On-line vacuum arrangement apparatus

A vacuum and vacuum treatment technology, which is applied in the field of vacuum refining treatment of molten steel in steelmaking plants of iron and steel enterprises, can solve the problems that the offline layout structure does not meet the production needs of higher RH vacuum treatment ratio, and save the time of driving, saving time, Effect of Tapping Temperature Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing.

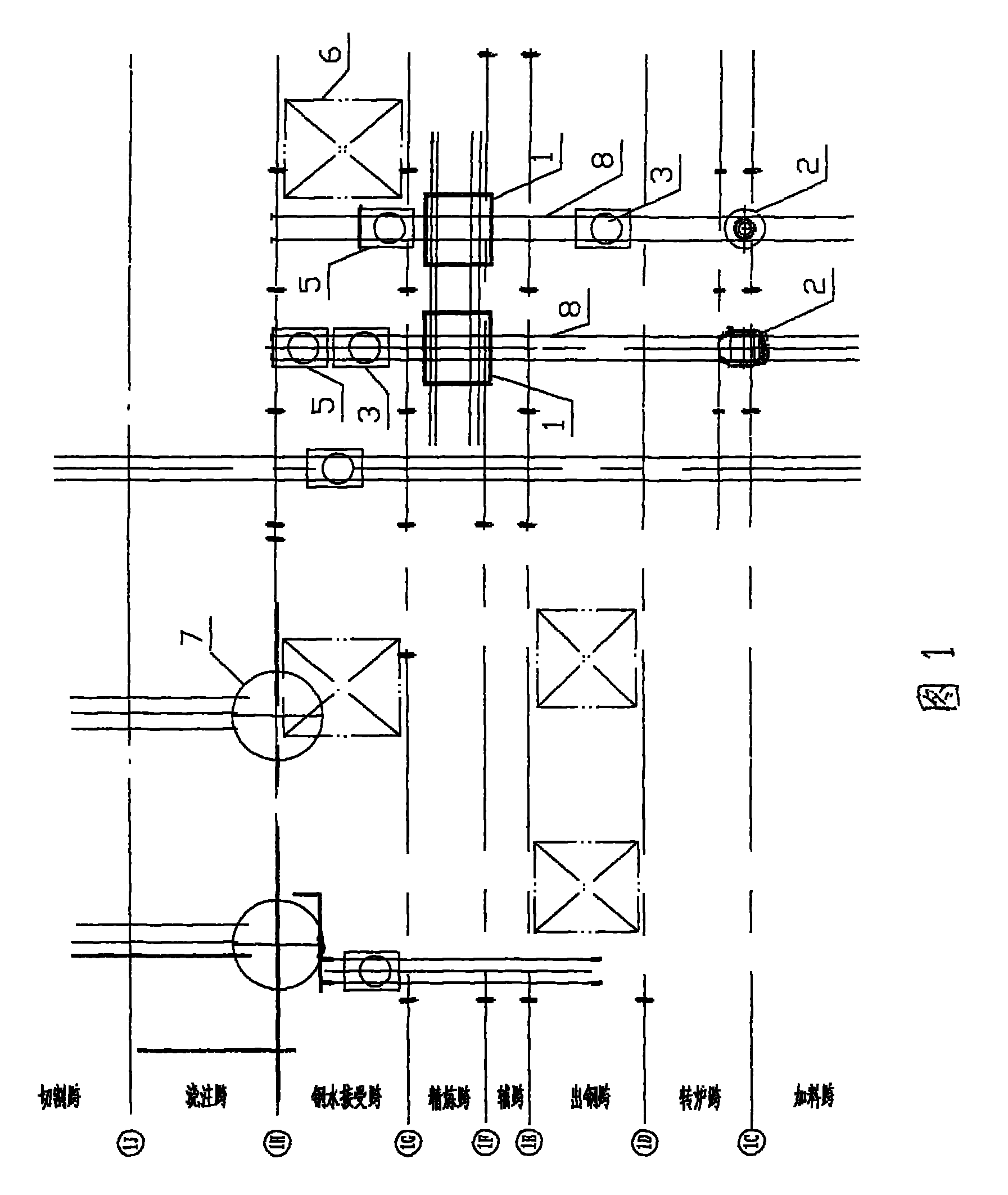

[0026] The vacuum online arrangement device includes a smelting furnace 2 and RH vacuum processing equipment 1 , and the RH vacuum processing equipment 1 is built above the tapping line 8 of the smelting furnace 2 . Two ladle cars are set on the tapping line 8 of the smelting furnace, one ladle car is responsible for transporting the molten steel after tapping the smelting furnace to the RH vacuum treatment equipment, this ladle car is called the ladle car 3 of the smelting furnace, and the other ladle car is responsible for Transport the molten steel treated by the RH vacuum treatment equipment to the molten steel receiving bay, and then be hoisted by the crane for continuous casting. This ladle cart is called RH ladle cart 5.

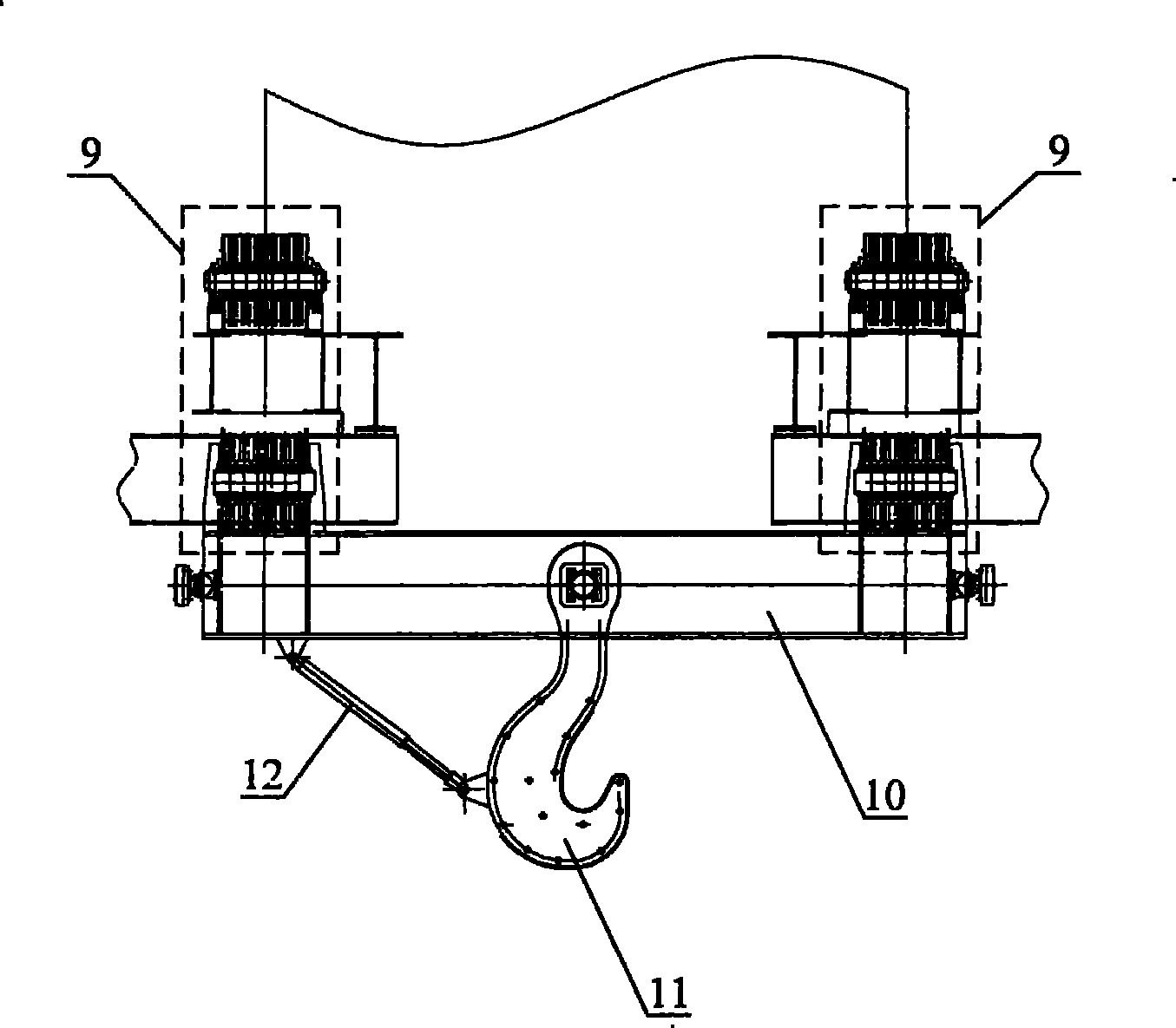

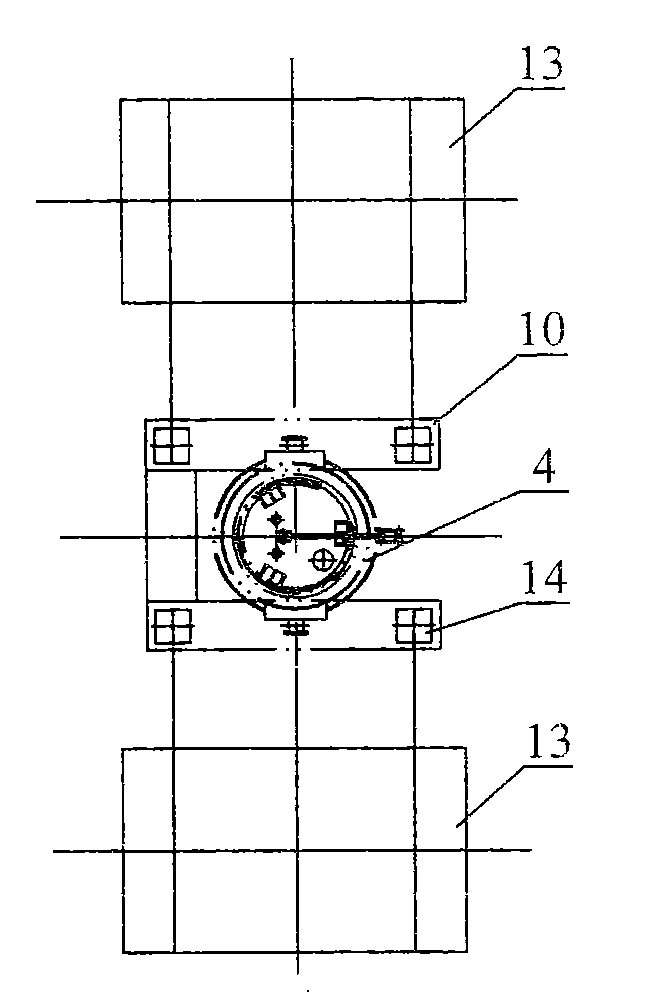

[0027] Simultaneously, a ladle hoisting device is provided above the RH vacuum treatment equipment 1, referring to Figure 2 to Figure 4 , it compri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com