Online rolling and hot-forming process of heat-state plate/strip and application thereof

A forming process and hot state technology, applied in the field of rolling in the iron and steel metallurgy industry, can solve the problems of thick steel plate, large section size, large equipment capacity, etc., and achieve low residual stress, small bending angle, and reduced processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

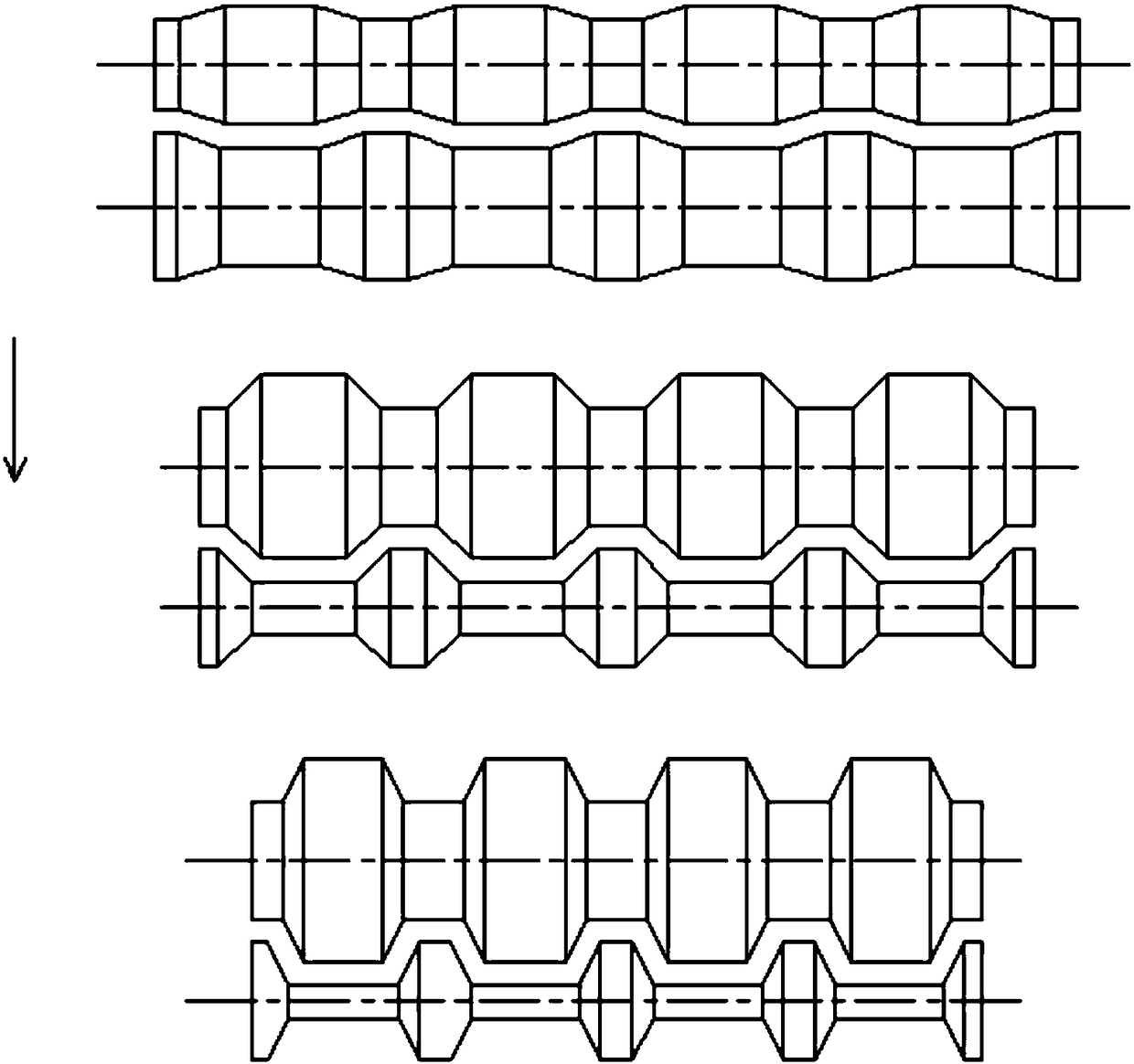

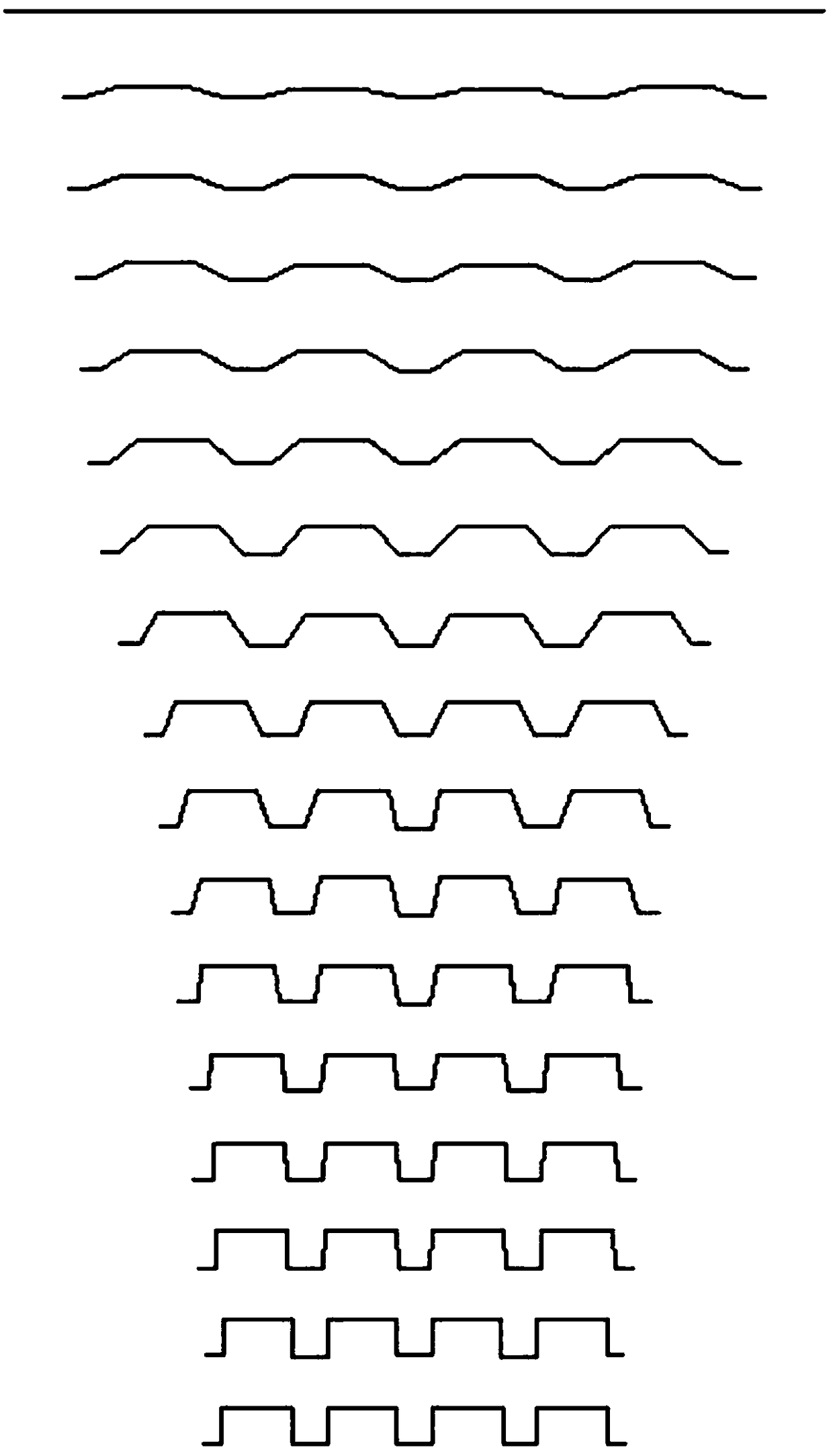

[0052] The invention provides an on-line rolling thermoforming process for hot plates / strips, which is used for hot bending forming of hot steel plates or strips, after the hot steel plates or strips are subjected to slitting process and hot bending process Become a section steel with a specified shape, wherein, the slitting process is before the hot bending process or the slitting process is after the hot bending process, and in the slitting process, the high temperature steel plate or strip is slit into strips; In the hot bending process, the high-temperature steel plate or steel strip is continuously hot-bent formed by the deformation roller group. The hot state and high temperature refer to the temperature range in which the steel plate or steel strip can be hot bent, and the temperature range is 500°C to 850°C.

[0053] This process utilizes the high temperature of the incoming material itself, which is convenient for continuous deformation of the plate or strip, and the ...

Embodiment 2

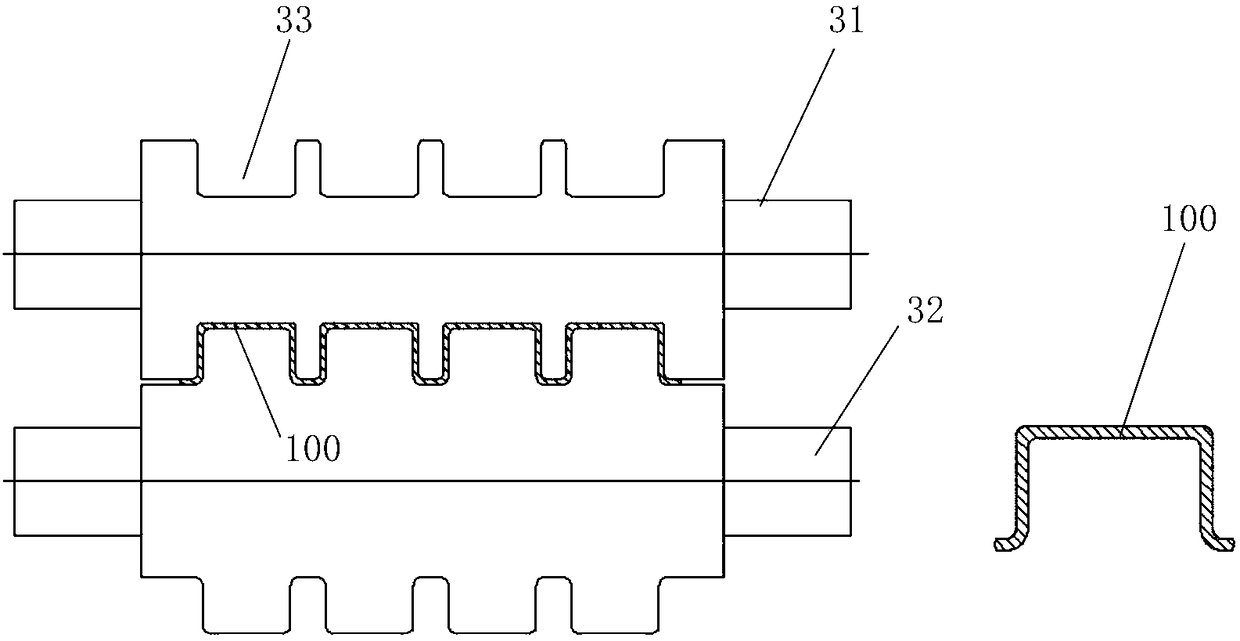

[0070] The present invention also provides an application of the online rolling thermoforming process of the hot plate / strip described in Embodiment 1 in the medium and thick plate rolling mill production line, the stations corresponding to the slitting process and the hot bending process (i.e. continuous hot bending Forming device 200) is arranged on the exit roller table of the medium and heavy plate rolling mill, see for details Figure 16 As shown, the continuous hot bending forming device 200 is arranged downstream of the finishing mill 104 of the medium and thick plate rolling mill production line, and the steel plate directly enters the slitting process and hot bending process from the rolling mill; thereby realizing continuous hot bending forming after hot rolling, fully utilizing The residual temperature of hot rolling.

[0071] Figure 15 Shown is a schematic elevational view of the continuous hot bending forming device 200 of the present invention arranged behind t...

Embodiment 3

[0079] On this basis, the present invention also provides an application of the online rolling thermoforming process of the hot plate / strip described in Embodiment 1 on the coil production line, wherein the continuous hot bending forming device 200 also includes the The slitting is before hot bending, the slitting is after hot bending, and the slitting and hot bending are carried out at the same time. The hot slitting unit 106 includes disc shearing and thinning cutting. The layout of the production line is similar to that of Embodiment 2, and the continuous hot bending forming device 200 is arranged behind the finishing mill or at the end of the rolling line. The difference is that the roughing mill 103 in this example is followed by a steckel mill 121 .

[0080] Figure 22 Shown is a schematic elevation view of the continuous hot bending forming device 200 of the present invention arranged behind the coil rolling mill 121 of the coil production line. Figure 23 It is a sch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com