Impact strength detection device for wine bottle packaging box

A technology of impact strength and testing devices, which is applied in the direction of measuring devices, impact testing, and testing of machine/structural components, etc. It can solve the adverse effects of measurement result analysis and judgment, the measurement height cannot be accurately determined, and the accuracy of measurement results is affected. problems, to achieve the effect of reducing the risk of unqualified products, simple structure, and saving testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

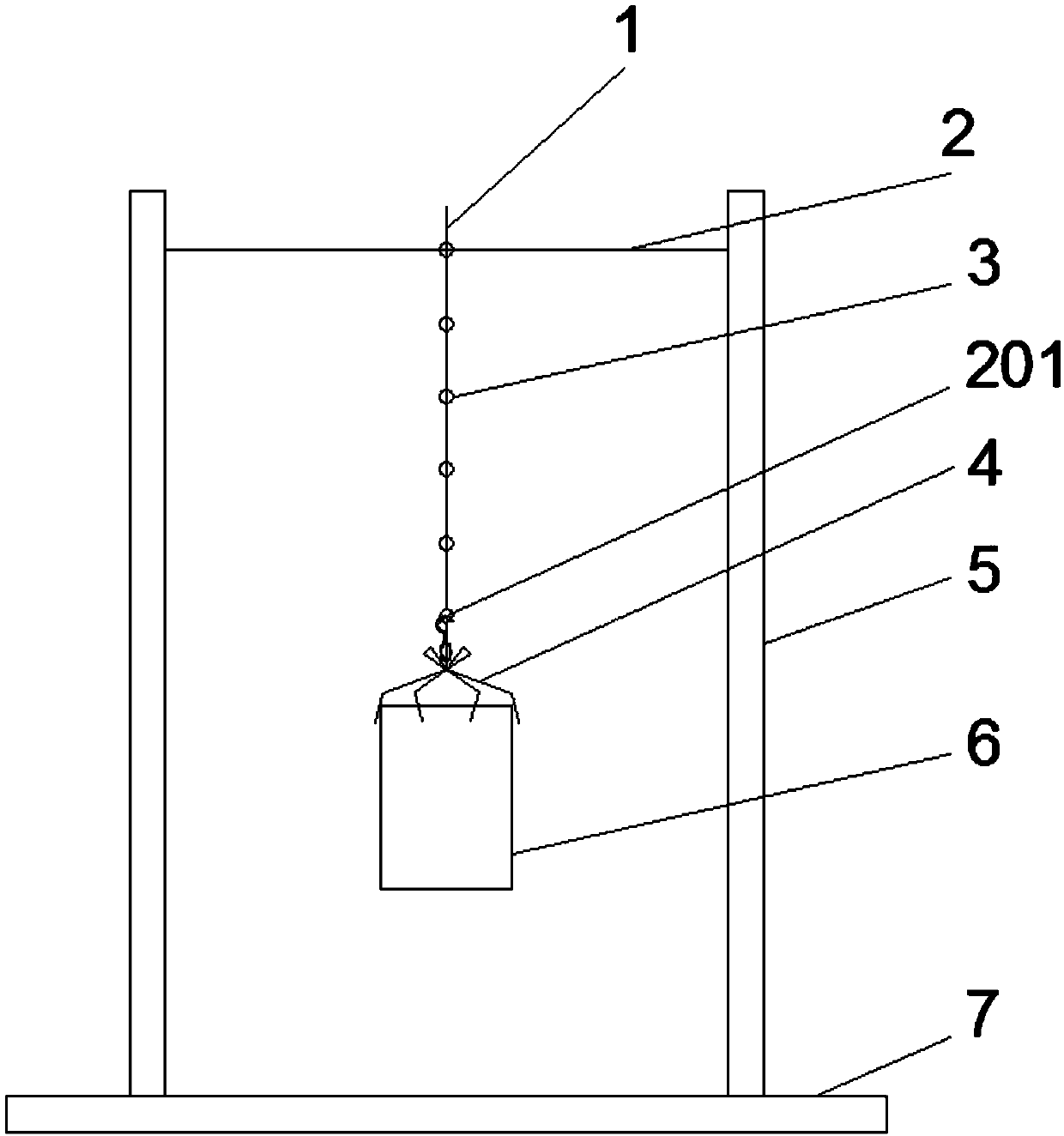

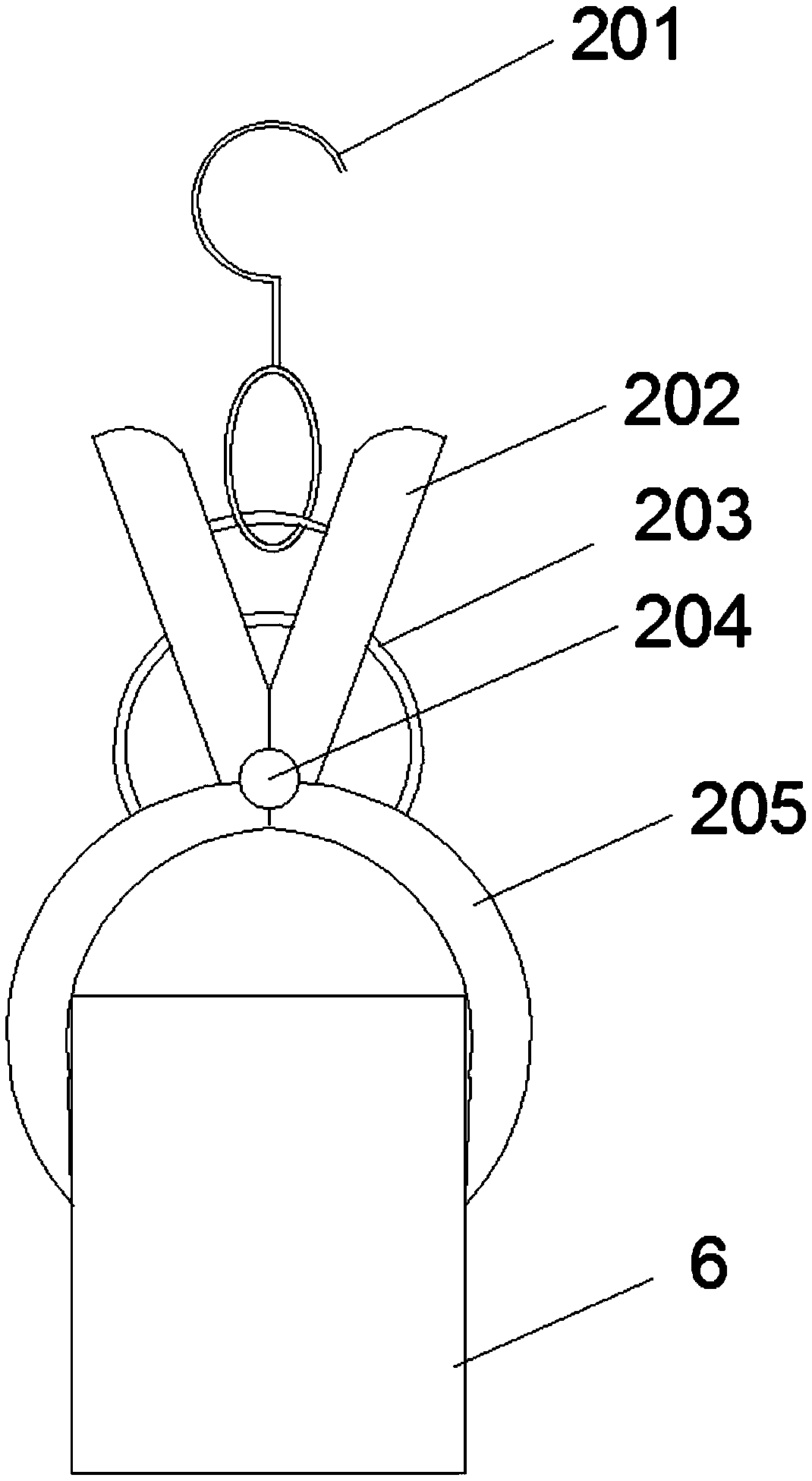

[0018] The technical scheme adopted in the present invention: as Figures 1 to 2 Shown is an embodiment of the present invention, a device for detecting the impact strength of a wine bottle packaging box, including a test platform 7, a door frame, a hanging chain 1 and a grasping part 4, and the door frame includes a vertically arranged on the test platform 7 Two support columns 5 on the top and a beam 2 erected between the support columns 5 and arranged horizontally with the test platform 7; one end of the lifting chain 1 is suspended on the beam 2, and the other end of the lifting chain 1 is connected to the grabbing Part 4, a plurality of ring-shaped hanging rings 3 are arranged on the hanging chain 1, and the distance between the hanging rings 3 is the same; the grabbing part 4 includes a handle for clamping the packaging box 6 and is connected with The hook 201 is detachably connected to the hanging ring 3 .

[0019] The gripper includes an opening and closing part 205, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com