Work order generation method and device

A technology for generating equipment and work orders, which can be applied in other database retrieval, other database retrieval, office automation and other directions based on metadata, and can solve problems such as affecting the normal operation of the work order engine, large instantaneous resource consumption, and unfavorable other tasks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

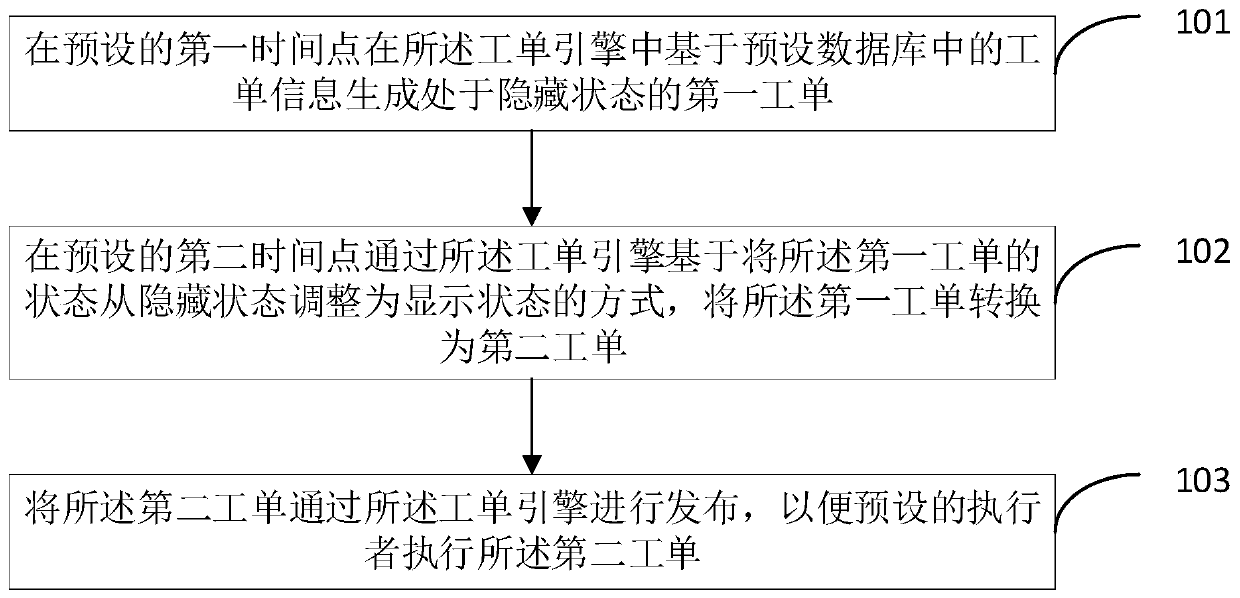

[0056]Embodiment 1 of the present invention discloses a method for generating work orders, which is applied to the generation process of periodic work orders in the work order engine, such as figure 1 As shown, the method includes the following steps:

[0057] Step 101: Generate a hidden first work order in the work order engine based on work order information in a preset database at a preset first time point; wherein, the work order information includes work order execution time information;

[0058] Specifically, for example, if the work order corresponding to the work order information is a scheduled maintenance work order, for example, if the work order execution time information is November 8, 2018, then at the first preset time point, for example, it can be 2018 The first work order was generated on November 6th. The first work order is hidden, that is, the first work order was actually generated, but it was not seen by the person to be executed.

[0059] Step 102: Con...

Embodiment 2

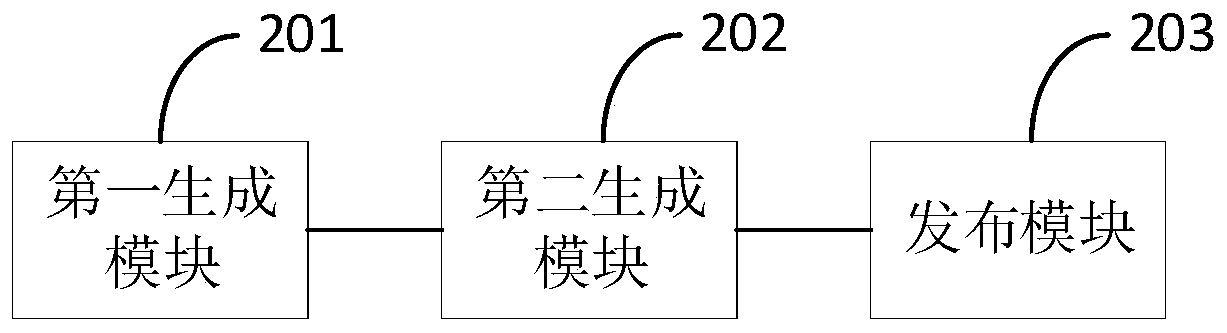

[0085] The embodiment of the present invention discloses a work order generation device, which is applied to the generation process of periodic work orders in the work order engine, such as image 3 As shown, the equipment includes:

[0086] The first generating module 201 is configured to generate a hidden first work order in the work order engine based on work order information in a preset database at a preset first time point; wherein, in the work order information Including work order execution time information;

[0087] The second generation module 202 is configured to convert the first work order by the work order engine based on the manner of adjusting the state of the first work order from a hidden state to a displayed state at a preset second time point It is a second work order; the first time point is earlier than the second time point; the time point corresponding to the work order execution time information is not earlier than the second time point;

[0088] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com