Lead crimping platform assembly

A wire crimping platform and wire crimping technology are applied in the direction of equipment for connecting/terminating cables, etc., which can solve problems such as low work efficiency, waste of manpower, material resources, labor and time, and achieve the effect of reducing burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

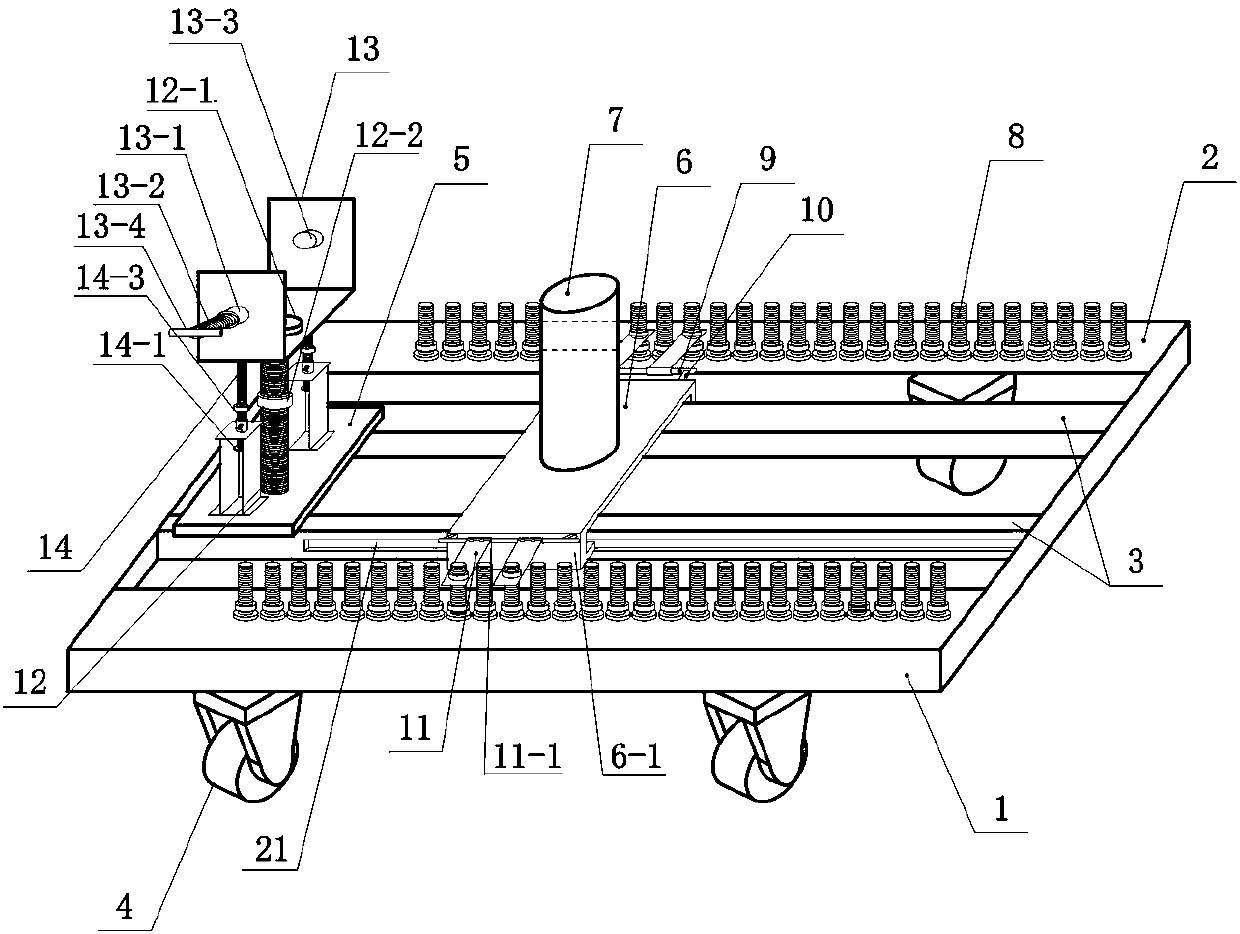

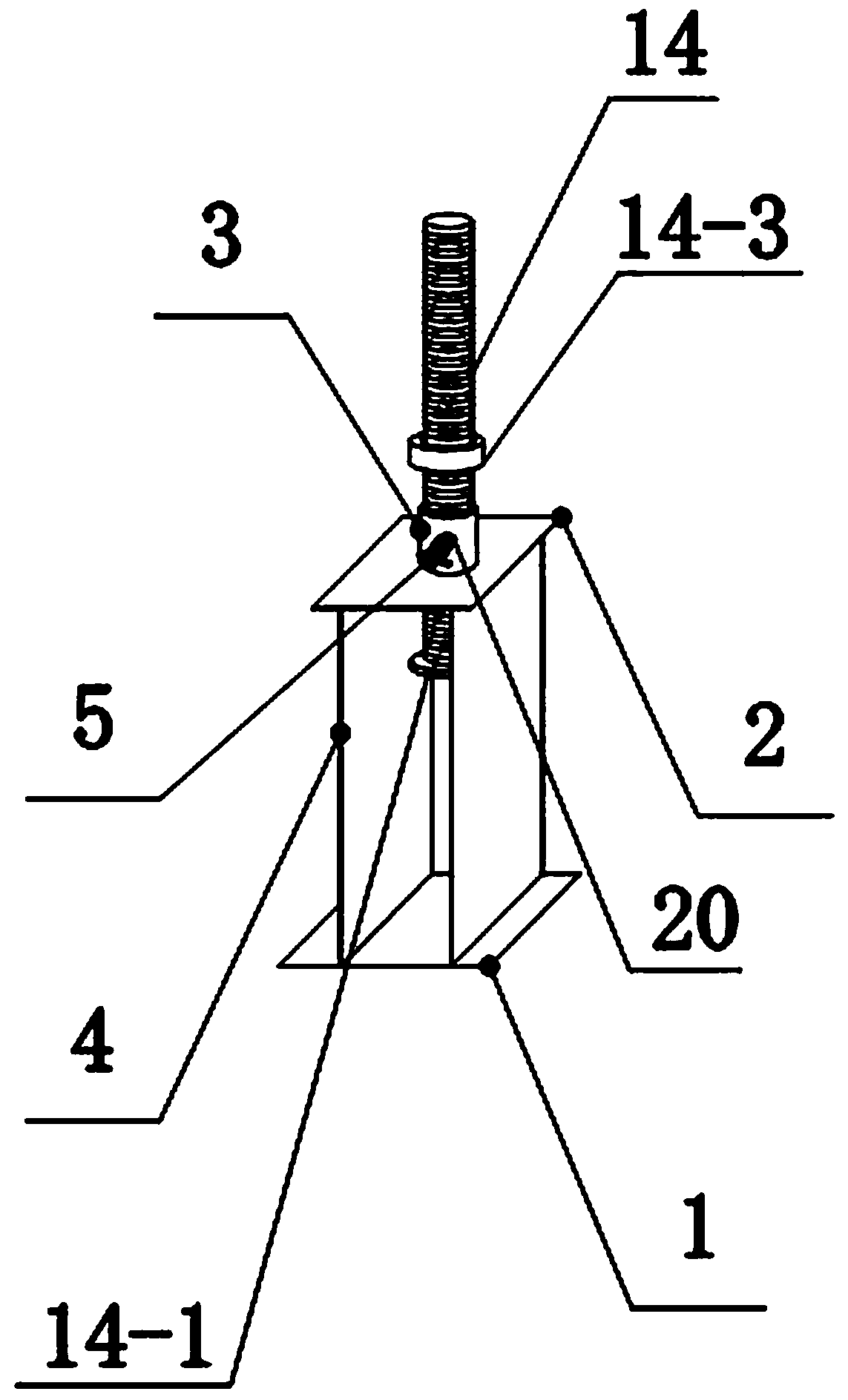

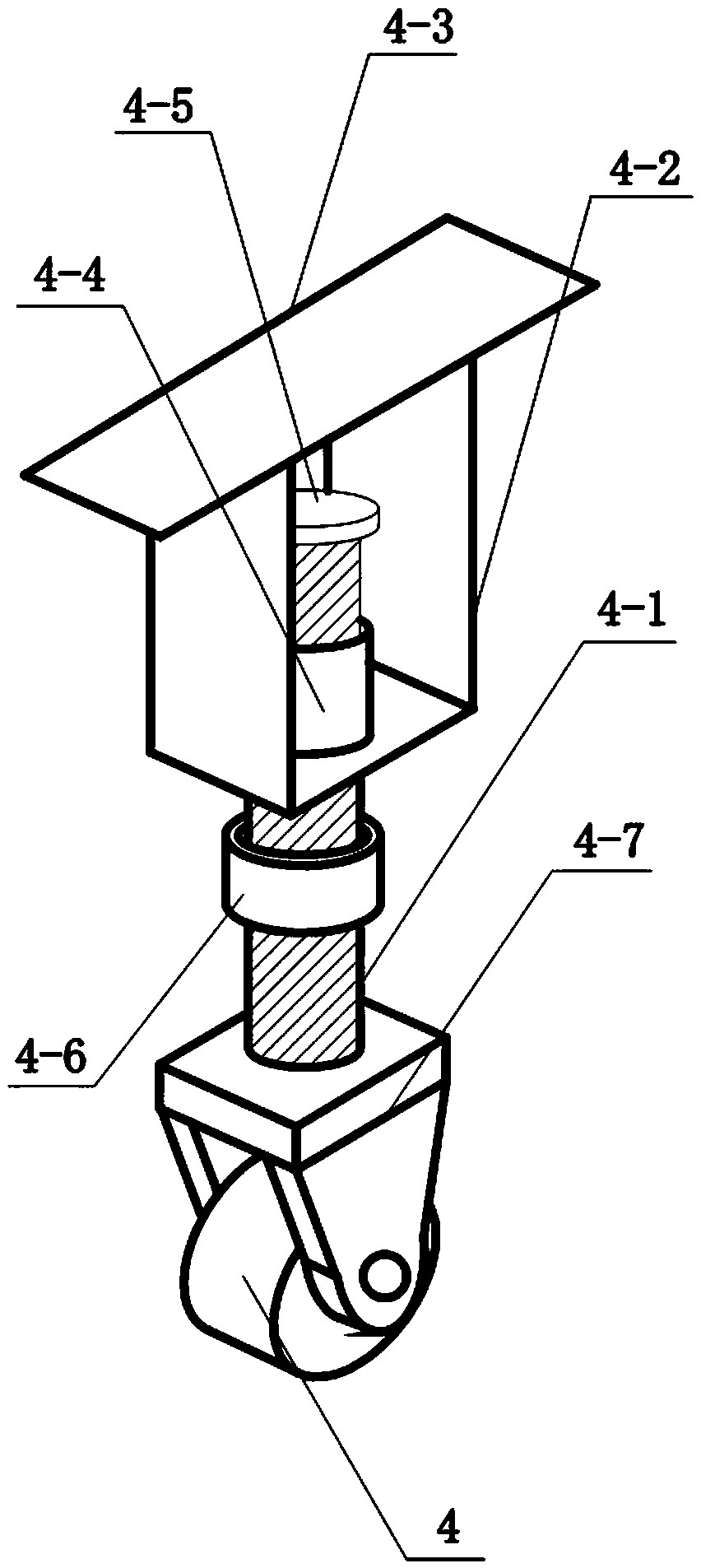

[0024] Introduce a drawing below to further explain and illustrate the present invention:

[0025] see Figure 1-Figure 3, a wire crimping platform assembly, including a bottom frame 1, a fixed plate 2, a connecting rod 3, a movable plate 6 and hydraulic wire crimping pliers 7, two fixed plates 2 are welded on the upper side of the bottom frame 1 respectively and the inside of the lower side; there are two connecting rods 3, which are respectively welded on the inner sides of the two bottom frames 1, and the two ends of the two connecting rods 3 are respectively fixedly connected with the inner walls of the bottom frame 1; the two connecting rods A bottom plate 5 is arranged between the left sides of the rods 3, and a wire adjustment mechanism is arranged on the bottom plate 5; a moving plate 6 is connected slidingly on the two connecting rods 3 on the right side of the bottom plate 5, and the two ends of the moving plate 6 are fixed. The "L"-shaped plates 6-1 are connected, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com