Linear motor

A linear motor, linear sliding technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of high input power and withstand voltage requirements, increase the difficulty of work, etc., achieve compact and reasonable structure, increase aesthetics, and facilitate The effect of maintenance repair or disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

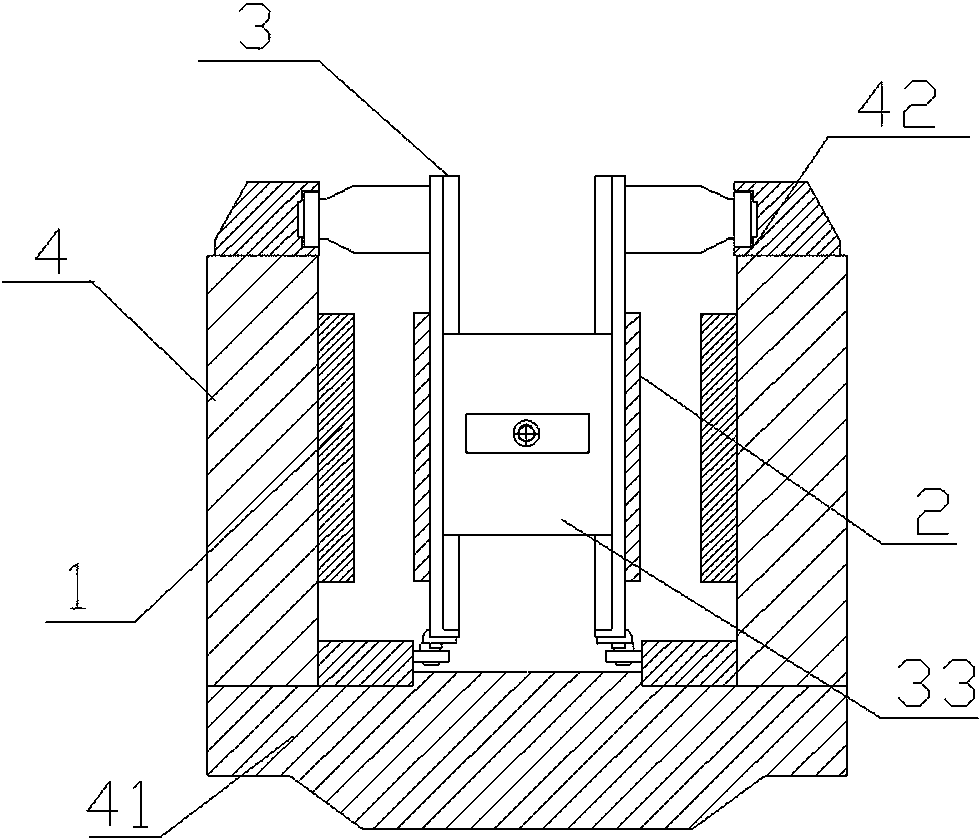

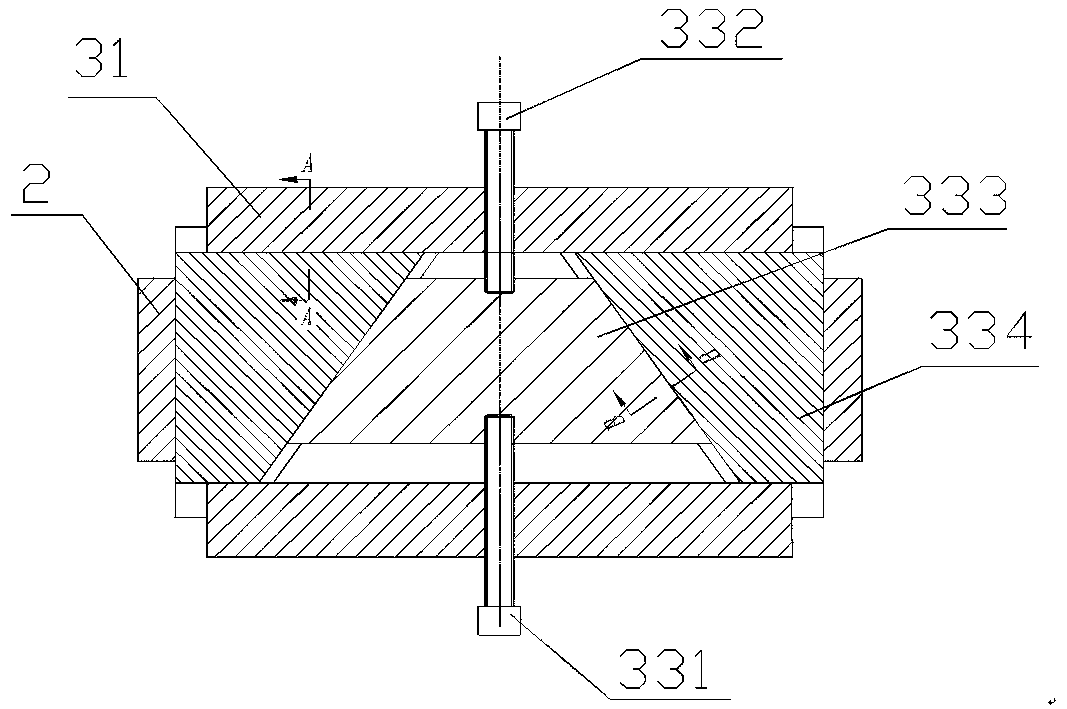

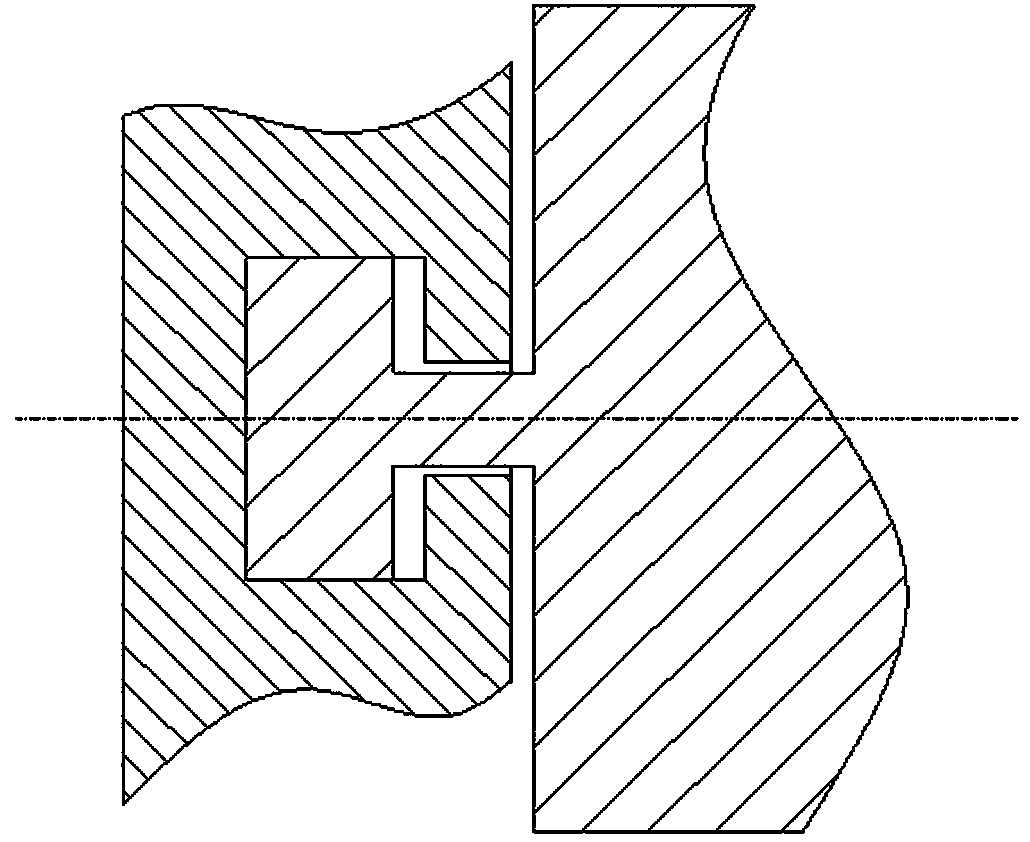

[0027] The present invention provides a linear motor, which includes two slideways 4 arranged in parallel. A group of primary modules 1 are respectively fixed on the inner sides of the two slideways 4. Two groups of primary modules 1 are symmetrically arranged, and a straight line is arranged between the two slideways 4. Slider 3, two sets of secondary modules 2 are fixed on both sides of the outer sides of the linear slider 3, wherein each set of secondary modules 2 and the primary module 1 are arranged oppositely, and there is a gap between the oppositely arranged secondary modules 2 and the primary module 1 Equally, the gap between the secondary module 2 and the primary module 1 is adjustable.

[0028] The above-mentioned primary module 1 is the primary of the motor, and the secondary module 2 is the secondary of the motor, both of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com