Cable-driven series-parallel palletizing robot with characteristics of light weight and high bearing capacity

A palletizing robot and cable-driven technology, which is applied in the stacking of objects, de-stacking of objects, and manipulators, etc., can solve the problems of large overall mass, small load, and poor dynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] Embodiments of the present invention will be described in detail below, and examples of the embodiments are illustrated in the drawings, in which the same or similar reference numerals represent the same or similar elements or elements having the same or similar functions. The following is exemplary, and is intended to be illustrative of the invention, not to be construed as limiting the invention.

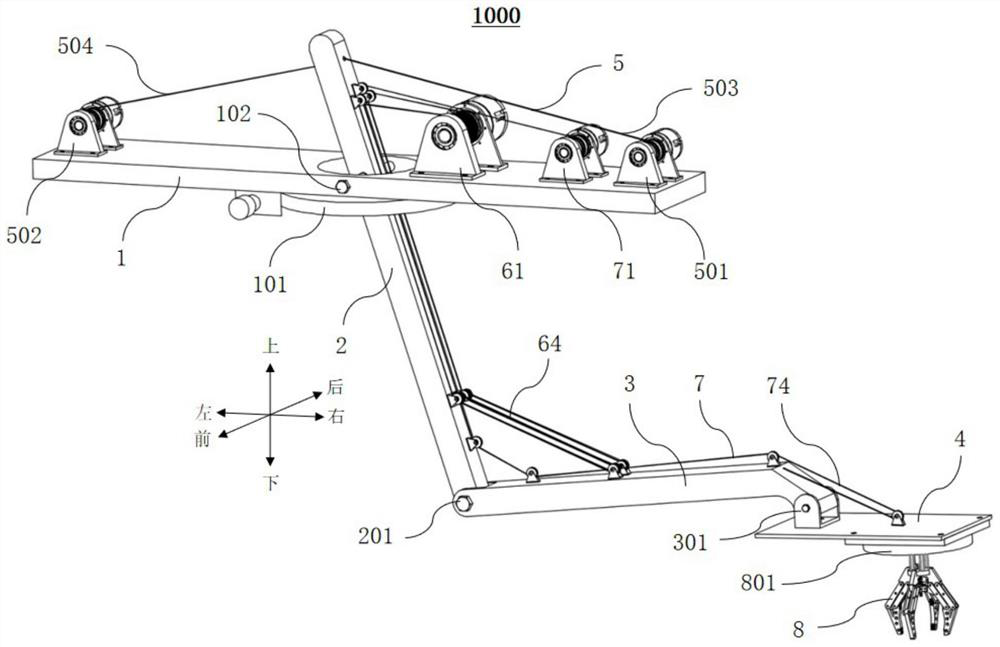

[0108] By below Figure 1 to 18 A ropolifier mixed chaitacler 1000 having a lightweight high bearing characteristic of the present invention is described herein.

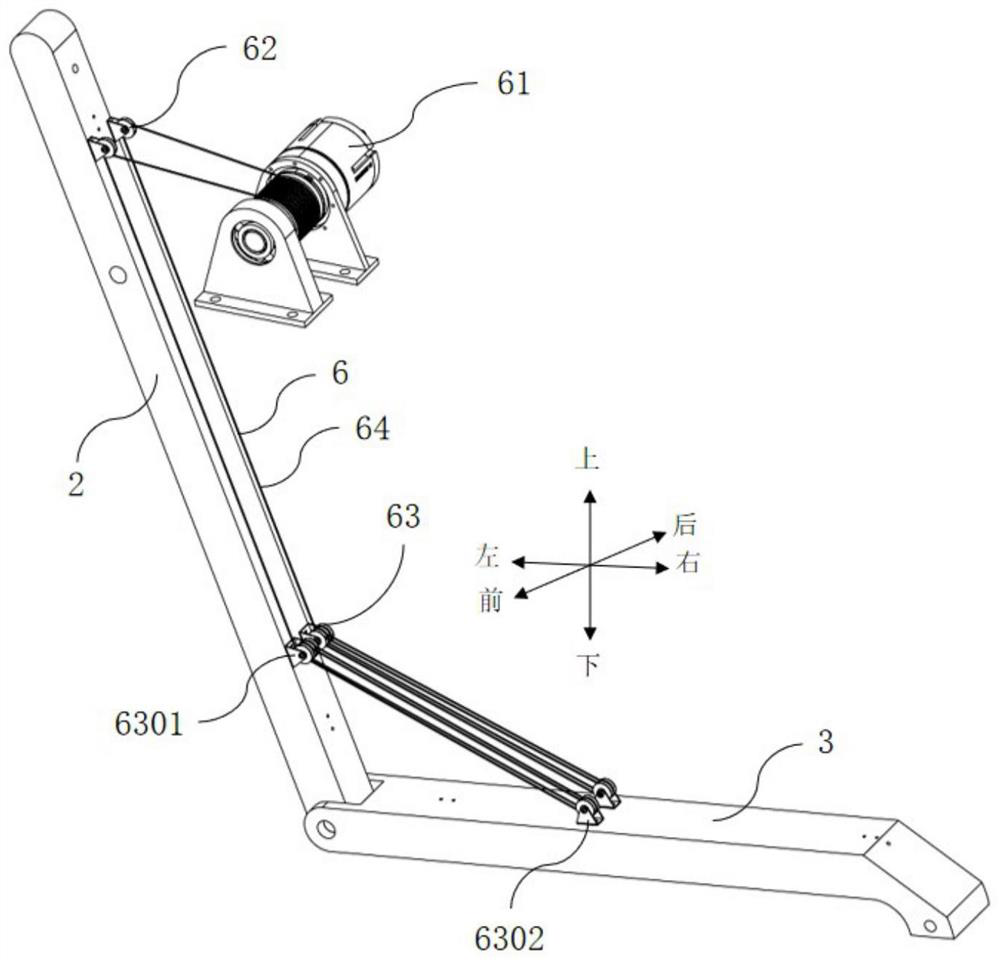

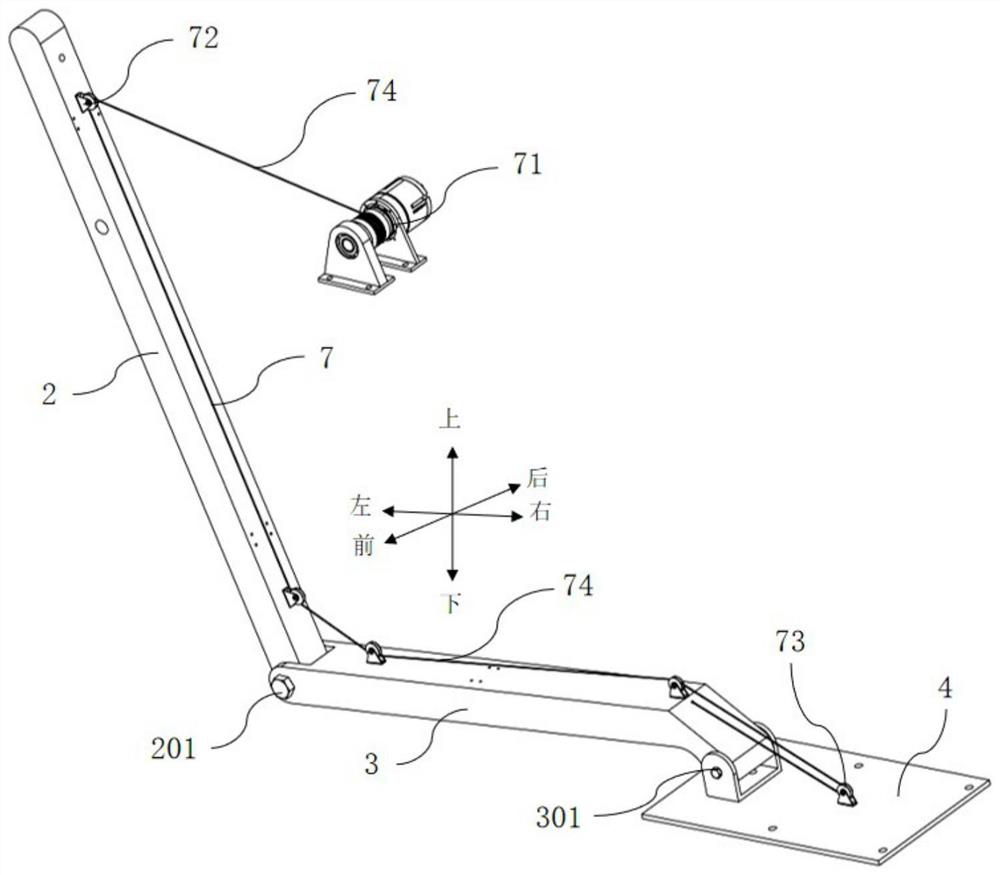

[0109] Such as figure 1 As shown, the ribo-drive mixed chalet of the present invention has a lightweight high bearing characteristic, including the base 1, the upper link 2, the lower rod 3, the connecting plate 4, shoulder softeduked branches. 5, elbow joint softening branches 6, wrist joint drive branches 7 and mechanical grab device 8. Among them, the rotary drive assembly 101 is mounted on the base 1, the rotary d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com