Modular oil film damping test device and method

A test device and modular technology, applied in the field of modular oil film damping test and modular oil film damping test device, can solve the problems of lack of effective scientific guidance for rational design of oil film damper, affecting the development and application of oil film damper, etc. The test method and device are simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

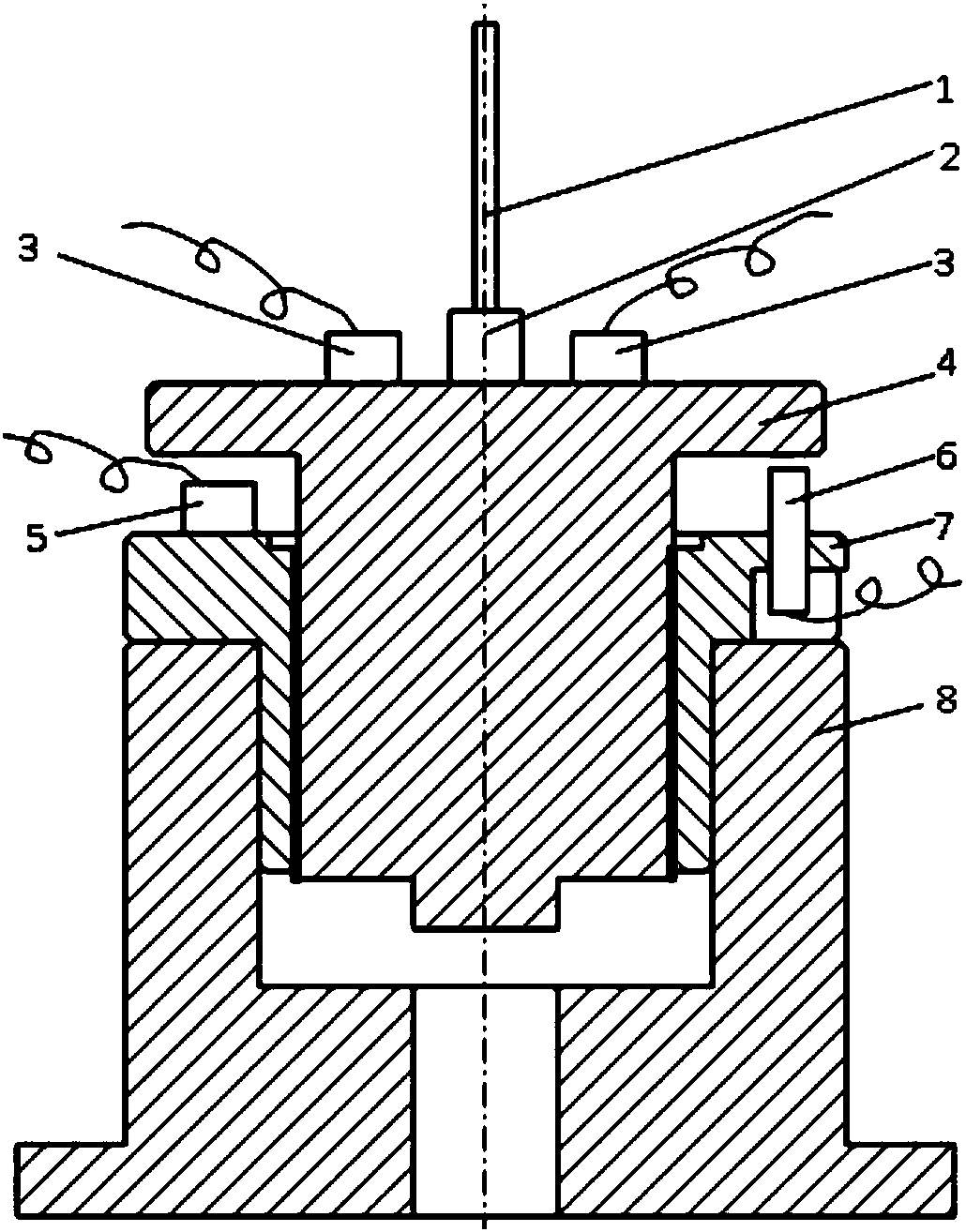

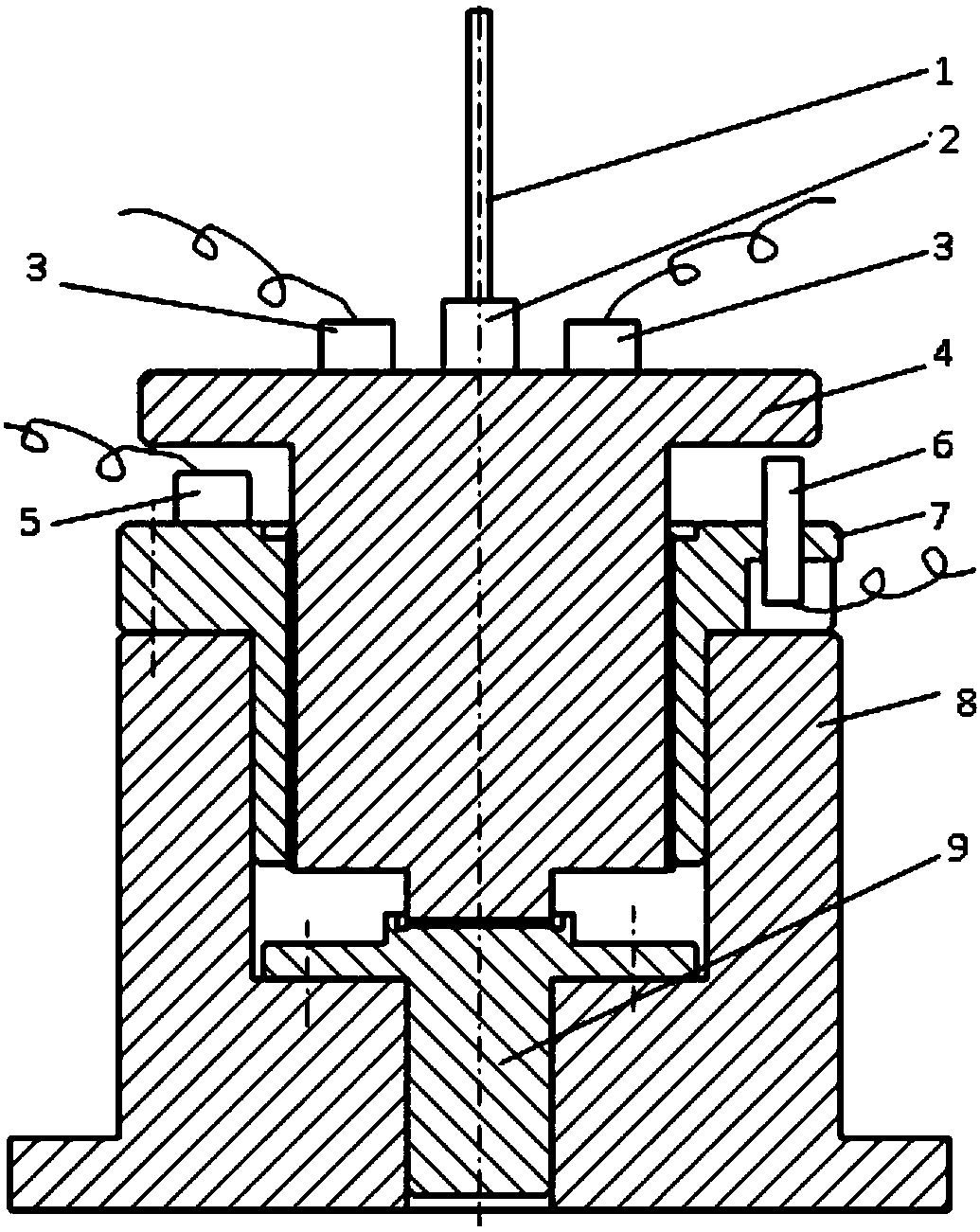

[0031] refer to figure 1 The structure of the device of the present invention is that the cylindrical upper test piece 4 is set in the sleeve 7 from top to bottom, and the contact surface of the upper test piece 4 and the sleeve 7 maintains a gap fit, and oil is injected into the gap to form an oil film. On the inner edge of the upper end surface of the sleeve 7 (near the gap side), there is an annular oil groove, which is filled with oil to maintain continuous oil supply to the oil film; the sleeve 7 is supported and fixed on the base 8 by the stepped flange on the outer periphery; A dynamic force sensor 2 is fixedly installed at the axial center position of the upper end surface of the piece 4, and the dynamic force sensor 2 is fixedly connected upward with an exciting rod 1, and an accelerometer-3 is installed on the upper end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com