Threshing device used in corn processing

A corn processing and peeling technology, applied in application, threshing equipment, agricultural machinery and implements, etc., can solve the problems of corn cob crushing and entrainment, and achieve the effect of avoiding crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

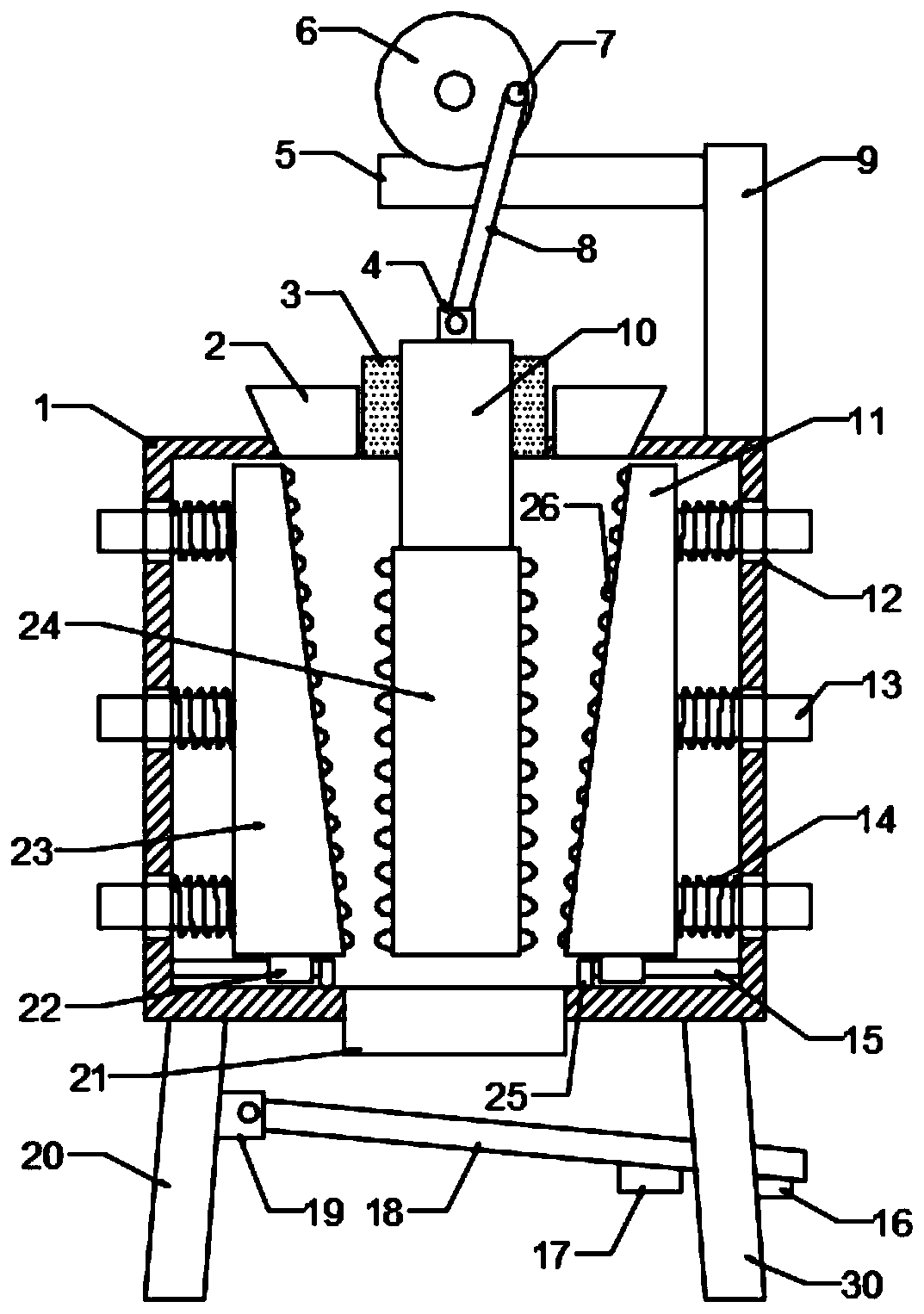

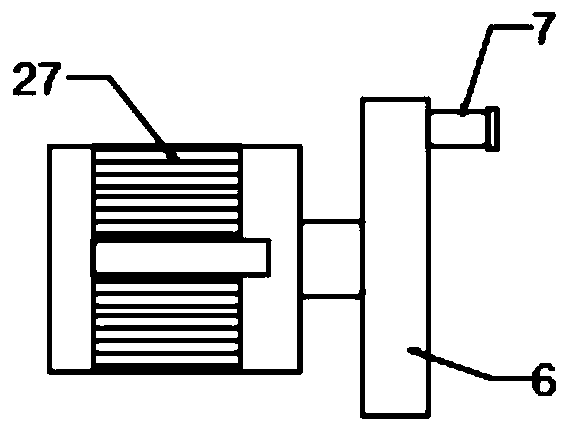

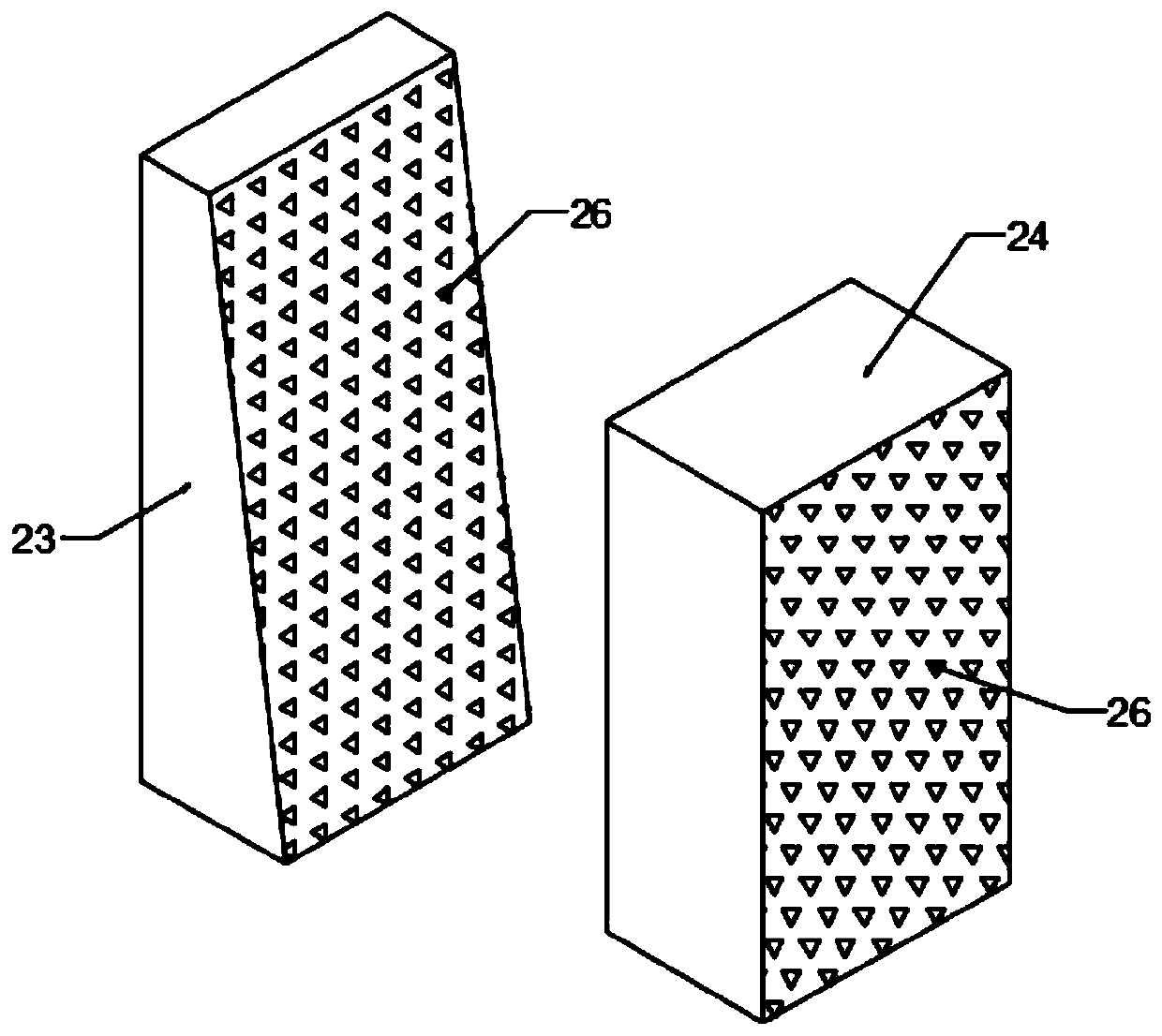

[0027] see Figure 1-3 , in an embodiment of the present invention, a peeling device for corn processing includes a box body 1, a first leg 20 and a second leg 30 are installed on the bottom of the box body 1, and on the top wall and the bottom wall of the box body 1 A hopper 2 and a discharge port 21 are respectively provided; a second wedge-shaped plate 23, a lifting plate 24 and a first wedge-shaped plate 11 are arranged in the box body 1, and the second wedge-shaped plate 23 and the first wedge-shaped plate 11 are positioned on the lifting plate. 24, the sides of the first wedge-shaped plate 11, the second wedge-shaped plate 23 and the lifting plate 24 are all provided with peeling protrusions 26, and the sides of the second wedge-shaped plate 23 and the first wedge-shaped plate 11 are all provided with slide bars. 13. The side wall of the box body 1 is embedded with a second guide sliding sleeve 12 that is slidingly matched with the sliding rod 13. The sliding rod 13 pass...

Embodiment 2

[0039] see Figure 4 , in the embodiment of the present invention, a peeling device for corn processing is different from embodiment 1 in that a support frame 29 is fixed on the second leg 30, and a deflector swash plate 28 is fixed on the support frame 29, The sloping plate 28 is positioned at the lower side of the sieve plate 18; the corn kernels falling from the sieve plate 18 fall on the sloping plate 28, and slide down along the sloping plate 28 after being diverted by the sloping plate 28, so as to facilitate collection .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com