Portable kitchen garbage granulating device

A waste-making and portable technology, applied in the field of portable kitchen waste granulation devices, can solve the problems of polluting the environment, high moisture content and easy breeding of bacteria, etc., achieve smooth surface, solve sanitation problems and high-value utilization problems, and uniform density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

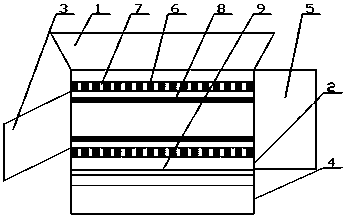

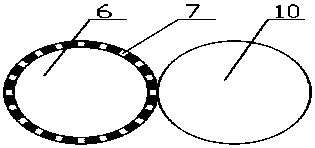

[0018] Such as figure 1 As shown, this embodiment provides a portable kitchen waste granulation device, which includes a hopper 1 and a connected cylinder 2; inside the cylinder 2 is provided a pair of forming rollers 6 and pressing rollers 10 that rotate synchronously and in different directions. The diameters are exactly the same, and they are respectively connected to the drive motors arranged on the side wall of the cylinder body; several granulation holes 7 are arranged on the forming roller 6; 8. A filter screen is provided under the forming roller 6 and the pressure roller; a drain tank 4 connected to the cylinder body 2 is provided below the filter screen 9, and the bottom of the drain tank is fixed to the slide rail.

[0019] The specific working method of the present invention is as follows: Put the kitchen waste into the hopper 1, and the kitchen waste enters the gap between the pressure roller 10 and the forming roller 6 under the action of the pressure roller 10, ...

Embodiment 2

[0021] This embodiment provides a portable kitchen waste granulation device, which includes a hopper 1 and a connected cylinder 2; inside the cylinder 2 there are synchronously rotating forming rollers 6 and pressing rollers 10, both of which have the same diameter. They are respectively connected with the driving motor arranged on the side wall of the cylinder body; several granulating holes 7 are arranged on the forming roller 6; 6 and the bottom of the pressure roller are provided with a filter screen; the bottom of the filter screen 9 is provided with a drainage groove 4 connected to the cylinder body 2, and the bottom of the drainage groove is fixed with the slide rail.

[0022] In this embodiment, both sides of the same pressing roller 6 are provided with forming rollers 6 that rotate in different directions synchronously with it, so that two sets of pressing work can be performed simultaneously in the cylinder, which improves the preparation efficiency of garbage particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com