Patents

Literature

30results about How to "Solve the problem of high value utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for comprehensively utilizing waste residues and liquid waste of animal biochemical products

InactiveCN102876763AHigh dissolution rateSolve UtilizationPeptide preparation methodsWater/sewage treatment bu osmosis/dialysisLiquid wasteMicrowave

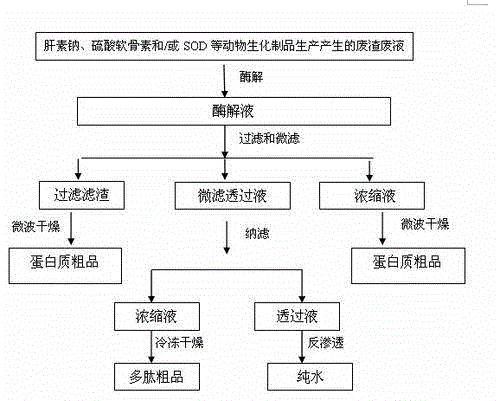

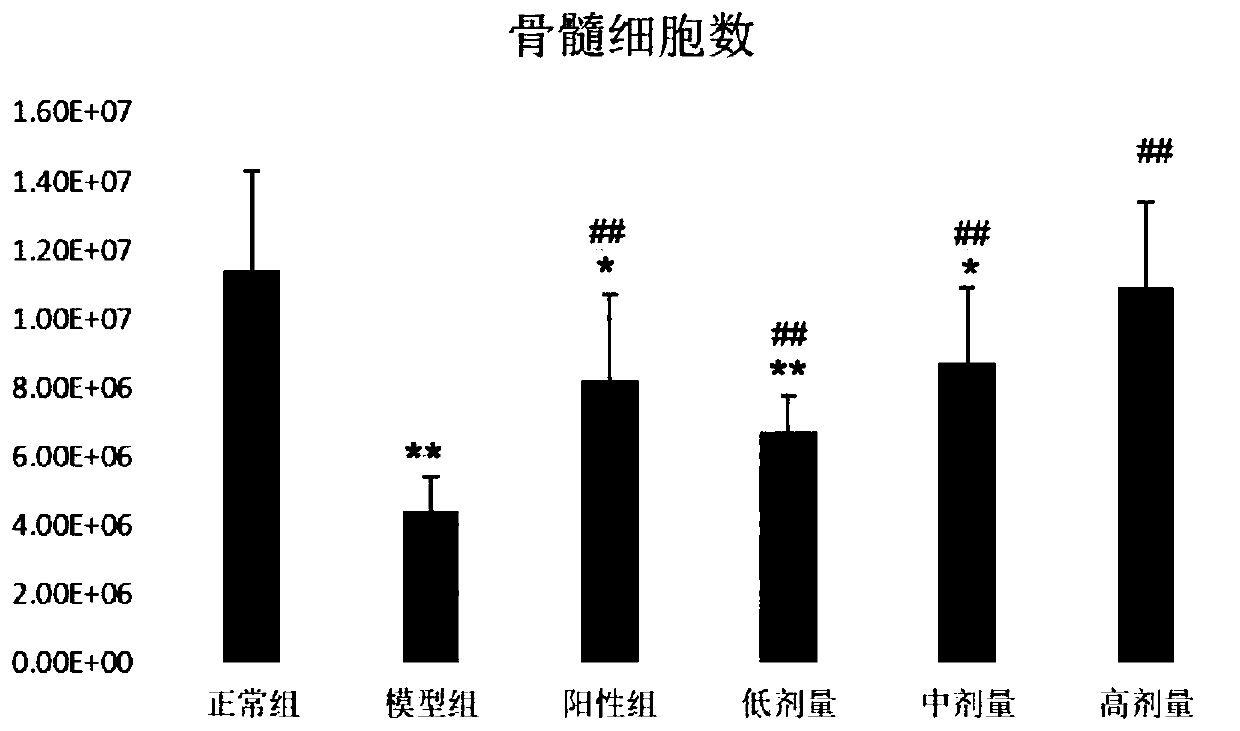

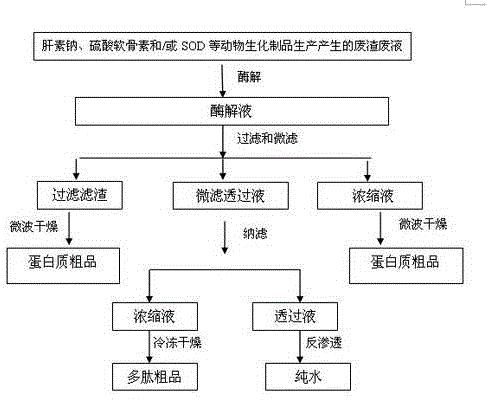

The invention relates to a method for comprehensively utilizing waste residues and liquid waste of animal biochemical products and belongs to the technical field of biology. The method includes steps of enzymolysis of waste residues and liquid waste; bag filtration of enzymolysis liquid to obtain filter residues and filtrate; filtrate filtering by a micro-filtration membrane to obtain concentrated liquid and permeating liquid; nanofiltration and concentration of the permeating liquid and obtaining concentrated liquid and permeating liquid; secondary nanofiltration and concentration of the permeating liquid to obtain concentration liquid and permeating filtrate; dechlorinating and purifying of the permeating liquid by the reverse osmosis technology and respectively collecting the concentrated liquid and the permeating liquid; mixing the concentrated liquid with the residues of the bag filtration, microfiltration and combining the concentrated liquid of the primary nanofiltration; vacuum drying via microwaves and obtaining animal protein crude products for feeding and edible animal protein crude products; freezing and drying of the concentrated liquid of the secondary nanofiltration and obtaining officinal polypeptide crude products. The method for comprehensively utilizing waste residues and liquid waste of the animal biochemical products is simple in process and low in production cost, products at various levels are good in quality, comprehensive utilization level of the waste residues and the liquid waste of the animal biochemical products is improved, and the problems about environmental pollution and high-valued utilization are solved.

Owner:四川茂森生物科技有限公司

Continuous reproduction technology using biomass wastes and waste liquid

InactiveCN105131984ARealize process continuous productionNot corrosiveBiocideOther chemical processesLiquid wasteGas phase

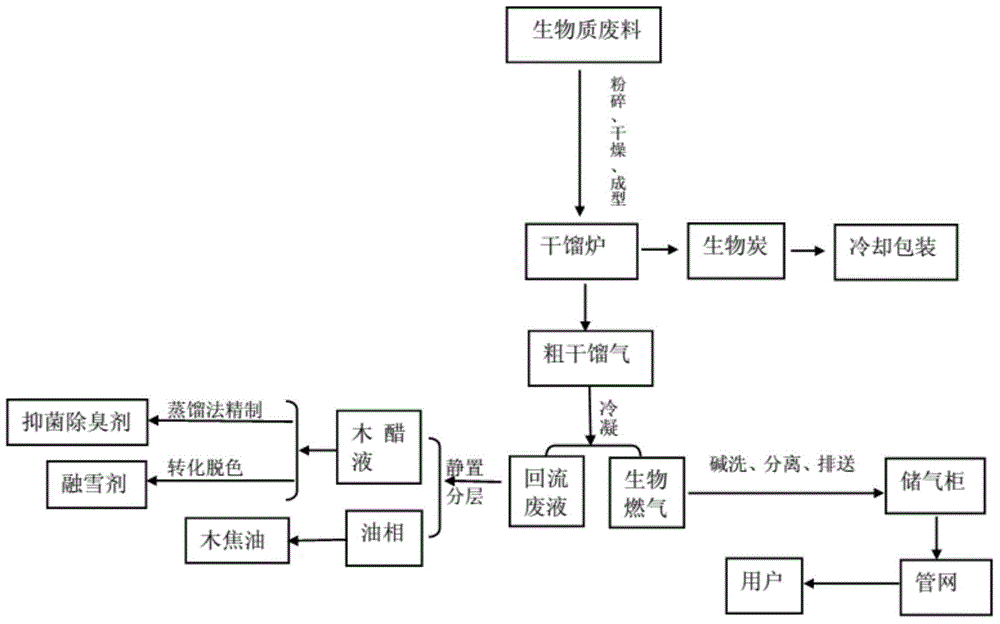

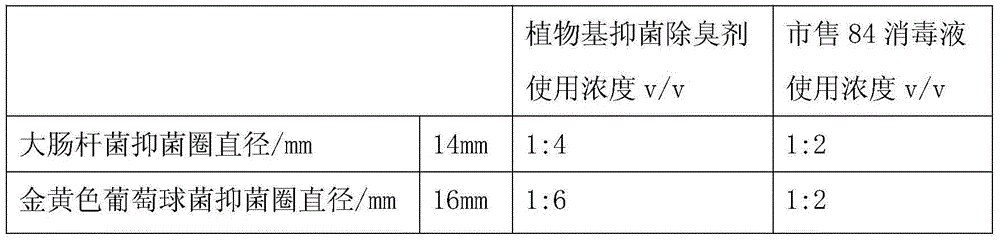

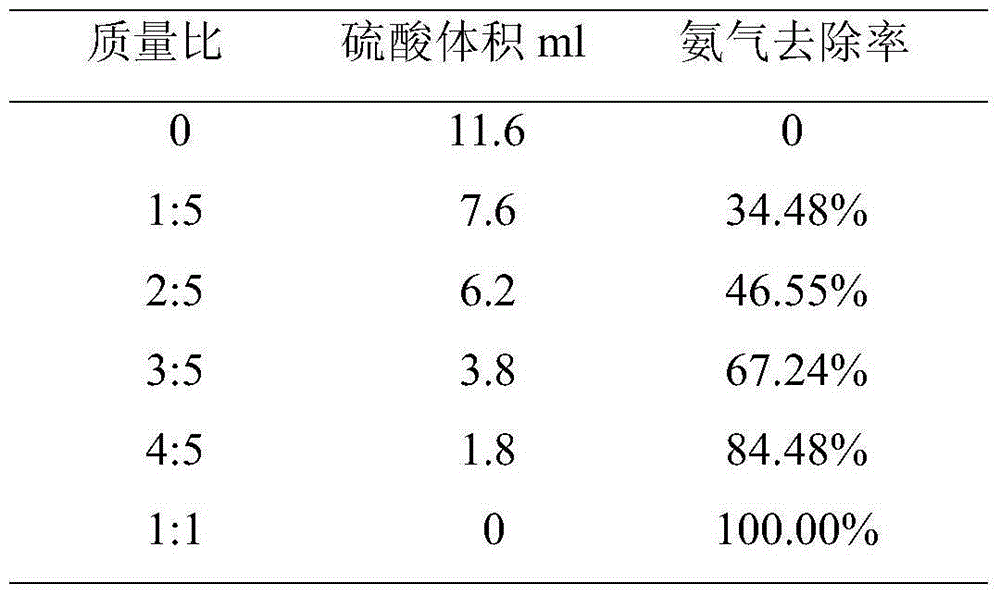

The invention provides a continuous reproduction technology using biomass wastes and a waste liquid. The technology comprises the following steps: crushing the biomass wastes, drying, molding, sending the obtained biomass wastes to a dry distillation furnace, and carrying out dry distillation to obtain charcoal and crude dry distillation gas; cooling charcoal, packaging to obtain a finished product, condensing the crude dry distillation gas to obtain a gas phase which is biogas, carrying out alkaline washing, separating, conveying to make the biogas enter a gas storage cabinet, and allowing the biogas to enter users through a pipe network; standing a refluxing waste liquid obtained after condensation of the crude dry distillation gas to realize layering and obtain an upper layer which is wood vinegar and a lower layer which is wood tar, collecting the wood tar, and packaging the collected wood tar to obtain a finished product; and determining organic matter components of the wood vinegar through gas chromatography-mass spectrometry, and respectively preparing a bacteriostasis and deodorization agent and an environmentally friendly botanical snow melting agent according to the content of acetic acid. The technology has the characteristics of continuousness, no emission of the waste liquid, and environmental protection, and solves the high value utilization problem of the waste liquid generated in the preparation of gas through biomass pyrolysis; and the bacteriostasis and deodorization agent has strong bacteriostasis, the ammonia odor removal rate can reach 100%, and the snow melting agent has the advantages of no corrosion, low snow melting temperature, chlorine harm eradication and excellent environmental protection performance.

Owner:DALIAN NATIONALITIES UNIVERSITY +2

Catalyst for low-temperature synthesis of methanol and preparation method

ActiveCN102773102ASolve the problem of high value utilizationLow costOrganic compound preparationHydroxy compound preparationReduction treatmentOrganic solvent

The invention relates to the production field of low-temperature synthesis of methanol, and particularly relates to a catalyst for low-temperature synthesis of methanol and a preparation method. The method includes the steps of: crushing and screening waste contacts generated from direct method production of methyl chlorosilane, and then using an organic solvent for cleaning. The method also can further include the following steps of: subjecting the cleaned waste contacts to one or more of an oxidation treatment, a reduction treatment and a heat treatment, thus obtaining the catalyst for low-temperature preparation of methanol from synthesis gas. The method provided in the invention solves the high value comprehensive utilization problem of solid residual waste contacts in the organosilicon synthesis industry. The prepared catalyst has the advantages of low raw material cost, simple operation method, as well as easy large-scale production, and shows higher methanol synthesis activity and thermal stability.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

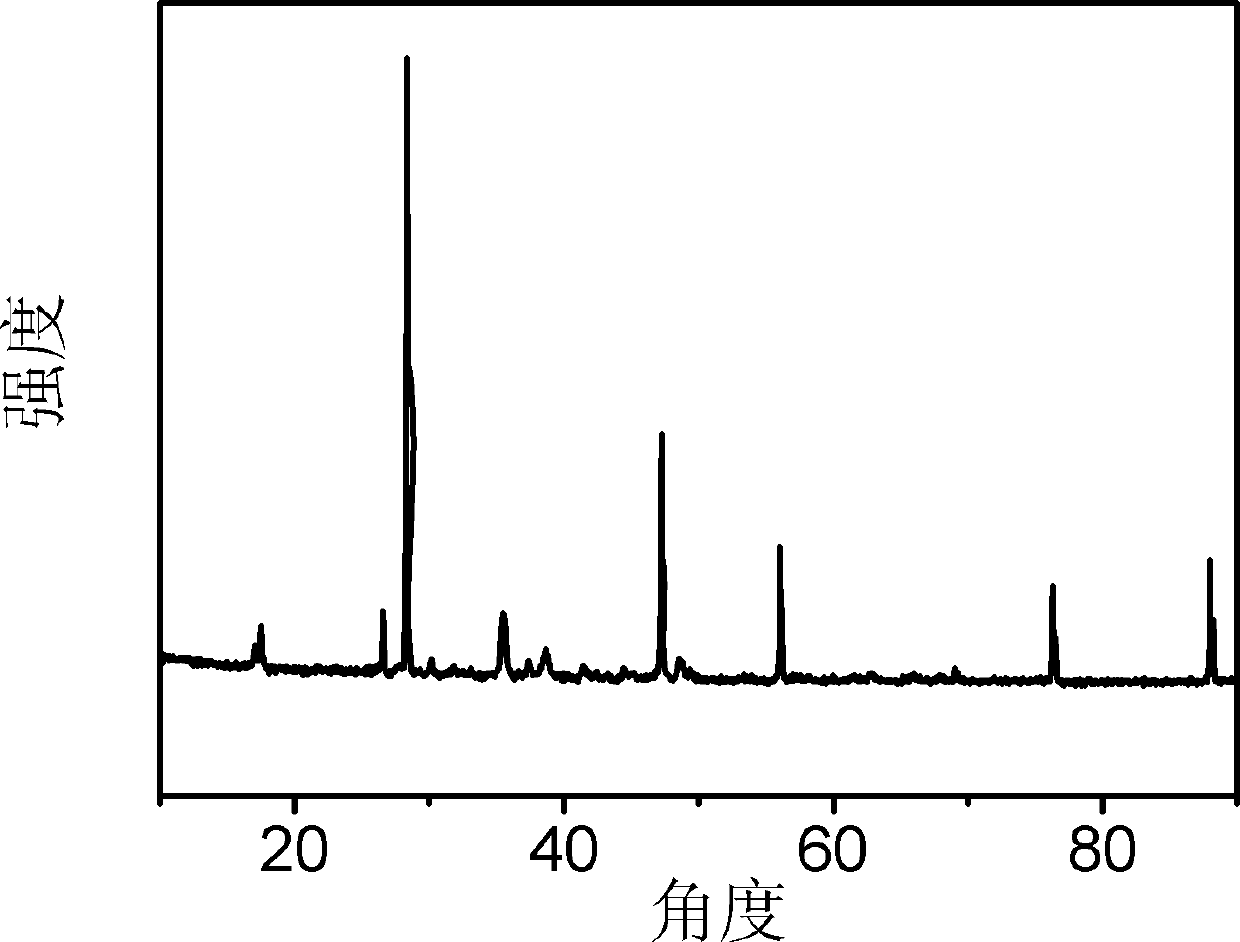

Preparation method of soil conditioner taking phosphogypsum as raw material

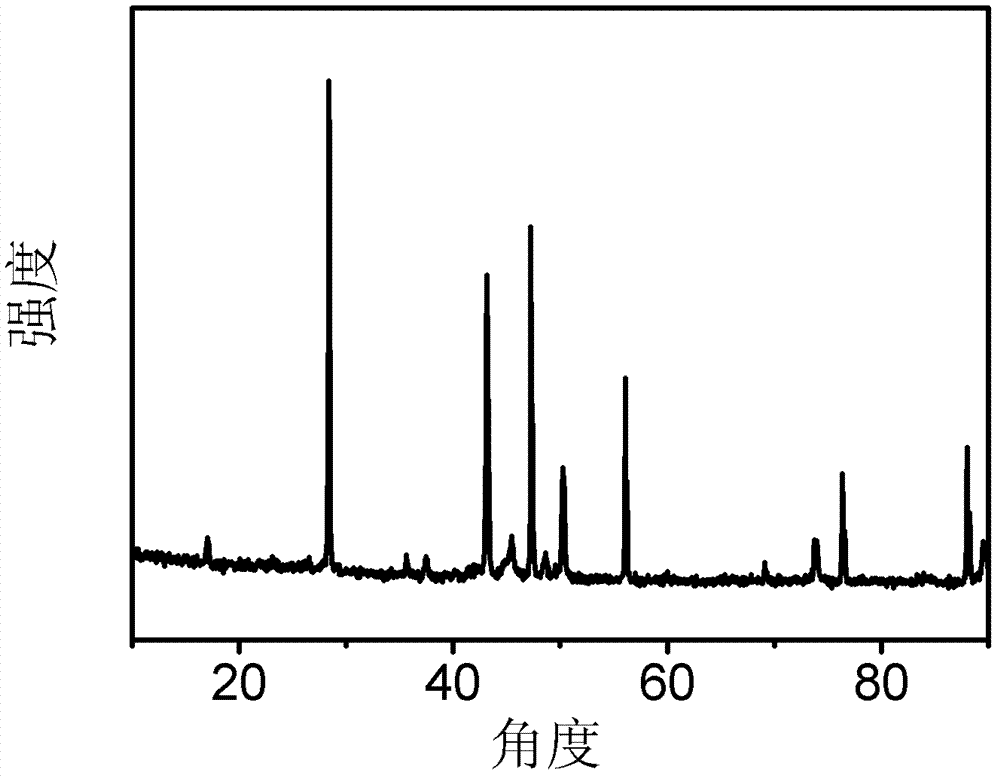

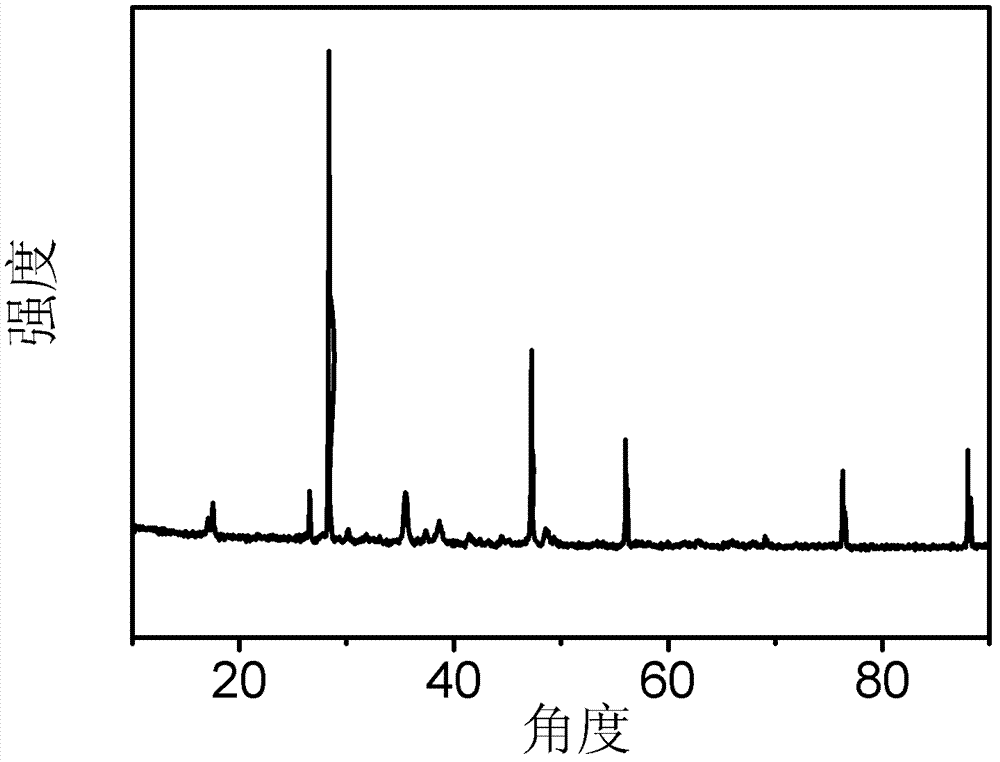

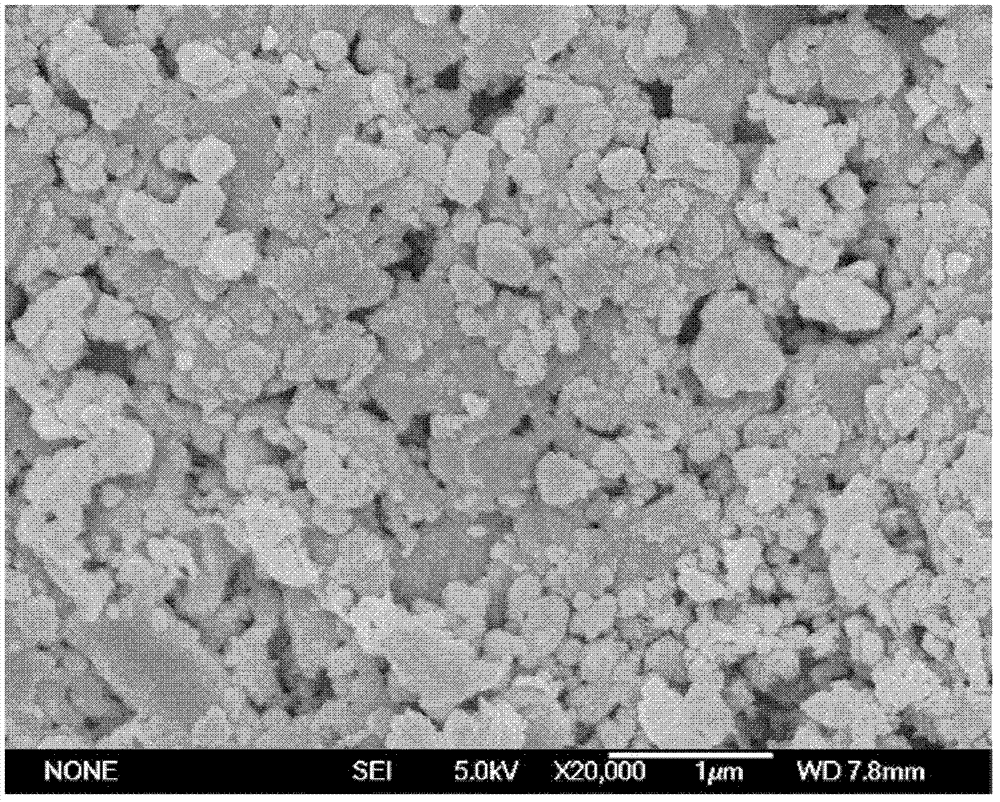

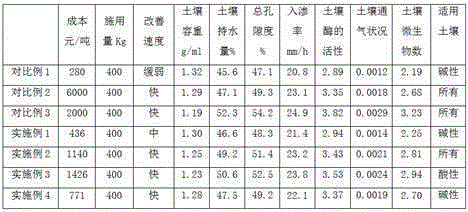

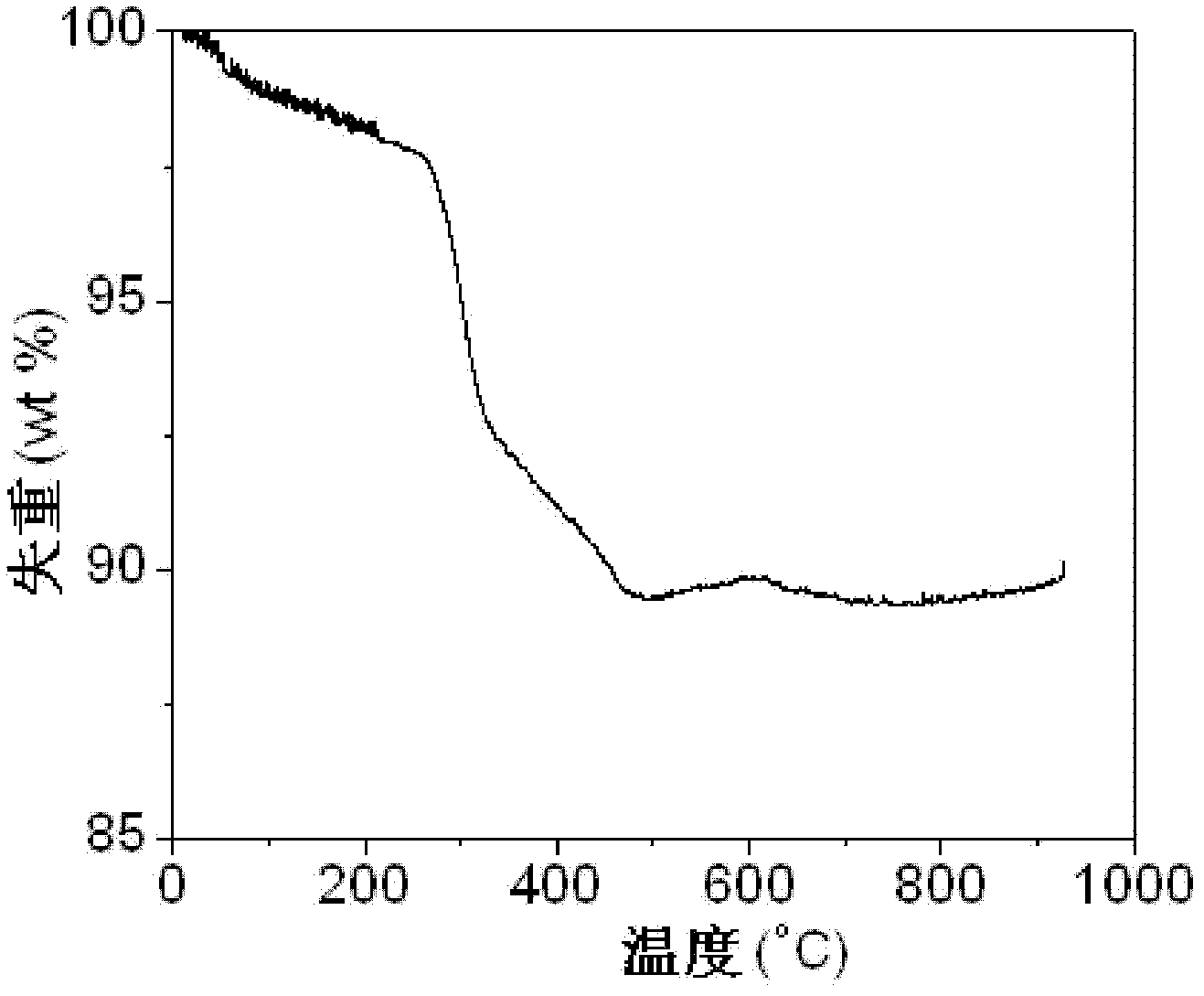

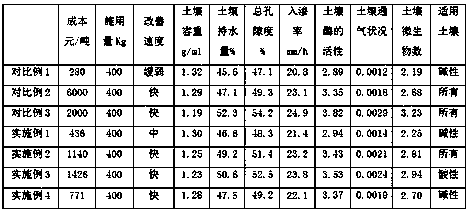

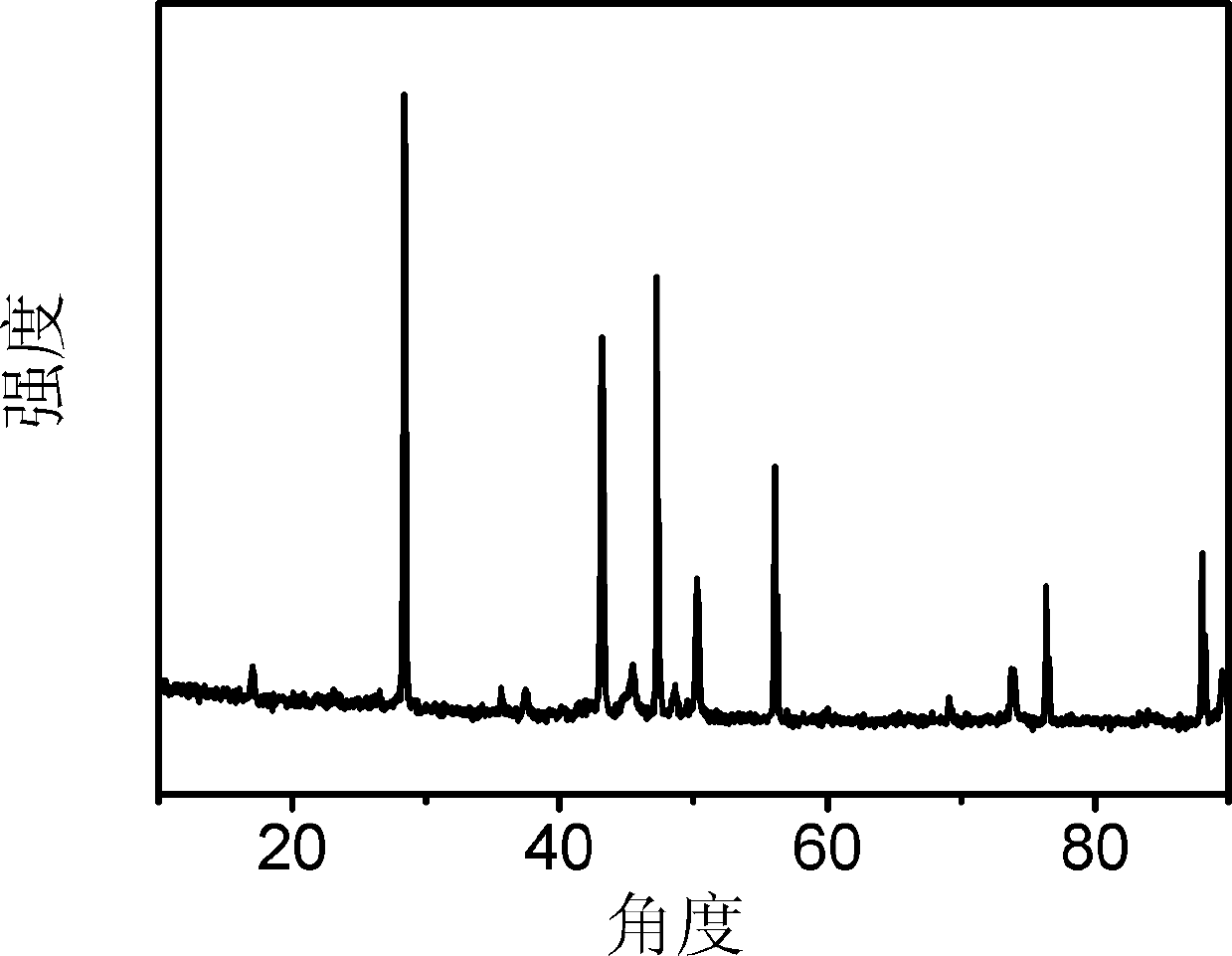

ActiveCN105001872AHigh specific surface areaImprove adsorption performanceAgriculture tools and machinesOther chemical processesChemistryAmmonium hydroxide

The invention discloses a preparation method of a soil conditioner taking phosphogypsum as a raw material, and belongs to the technical field of phosphogypsum resource utilization. The preparation method comprises the steps of smashing the raw material, namely the phosphogypsum, and mixing with wet-process activated carbon evenly according to a certain ratio, then adding ammonium hydroxide or ammonia-nitrogen wastewater to carry out an acid-base neutralization reaction, obtaining a solid product and filter liquor after performing solid-liquid separation on a reactant, and drying the solid product to obtain the soil conditioner. The obtained soil conditioner is charcoal grey and in the shape of amorphous wet powder particle, has flexibility and elasticity, has no dust, has high specific surface area and high adsorptive property, and meanwhile, contains multiple nutritional ingredients required by the growth of crops, wherein ammonium hydrogen phosphate and ammonium dihydrogen phosphate have the capabilities of adjusting and stabilizing the pH value. The soil conditioner strengthens the capability of conditioning soil, increases the storage property, and really has eurytopicity, specificity, versatility, environmental protection property and economy.

Owner:赵常然

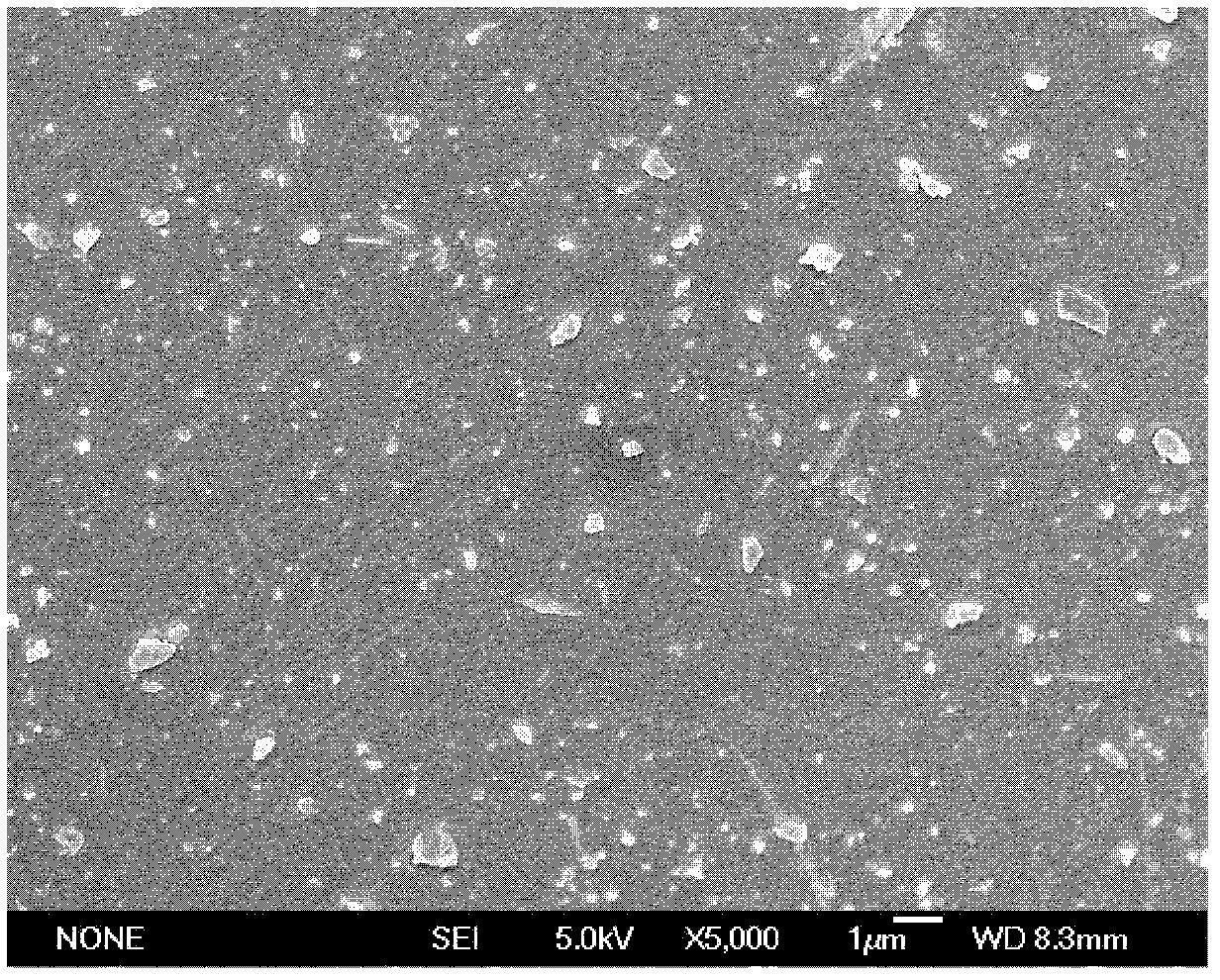

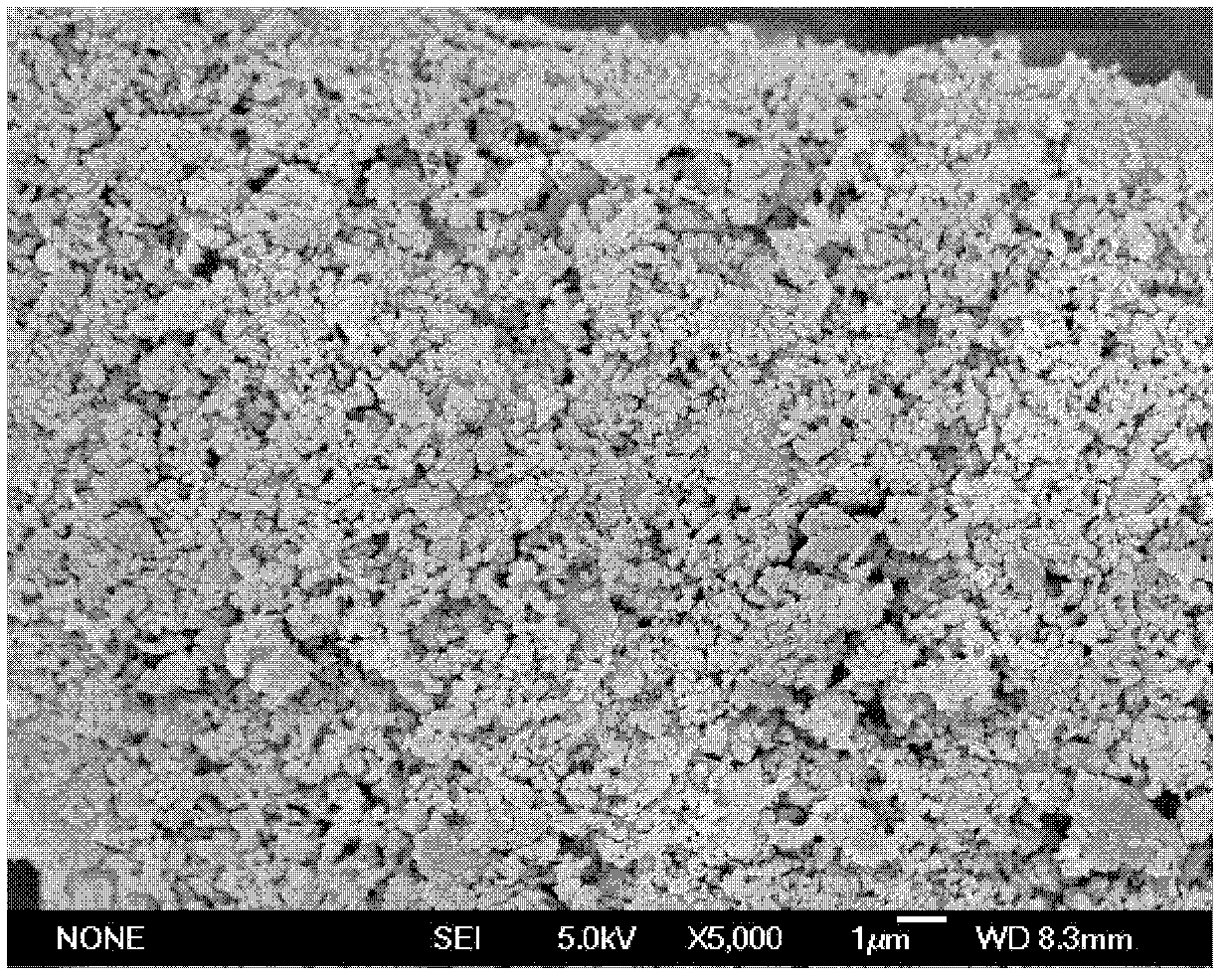

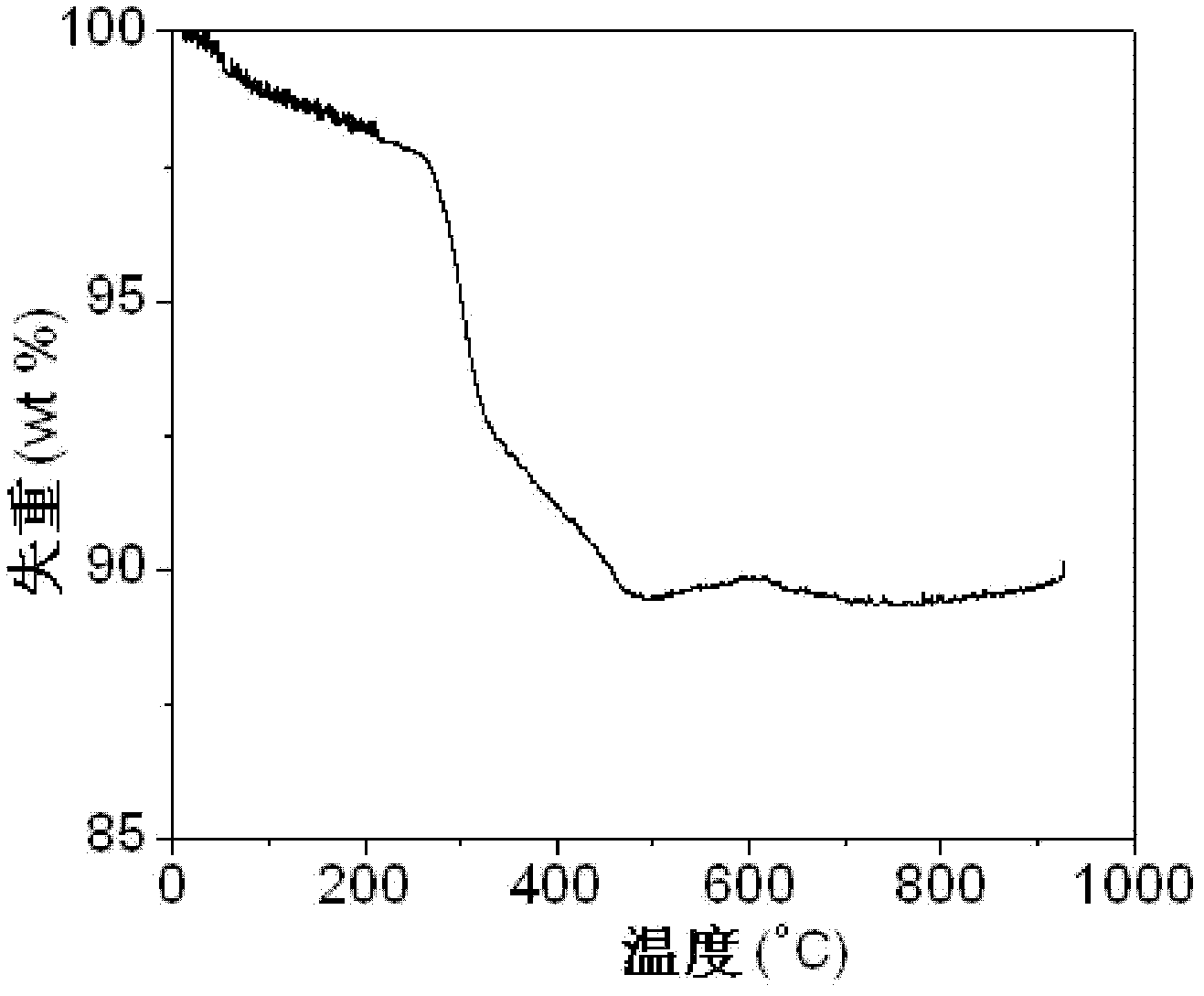

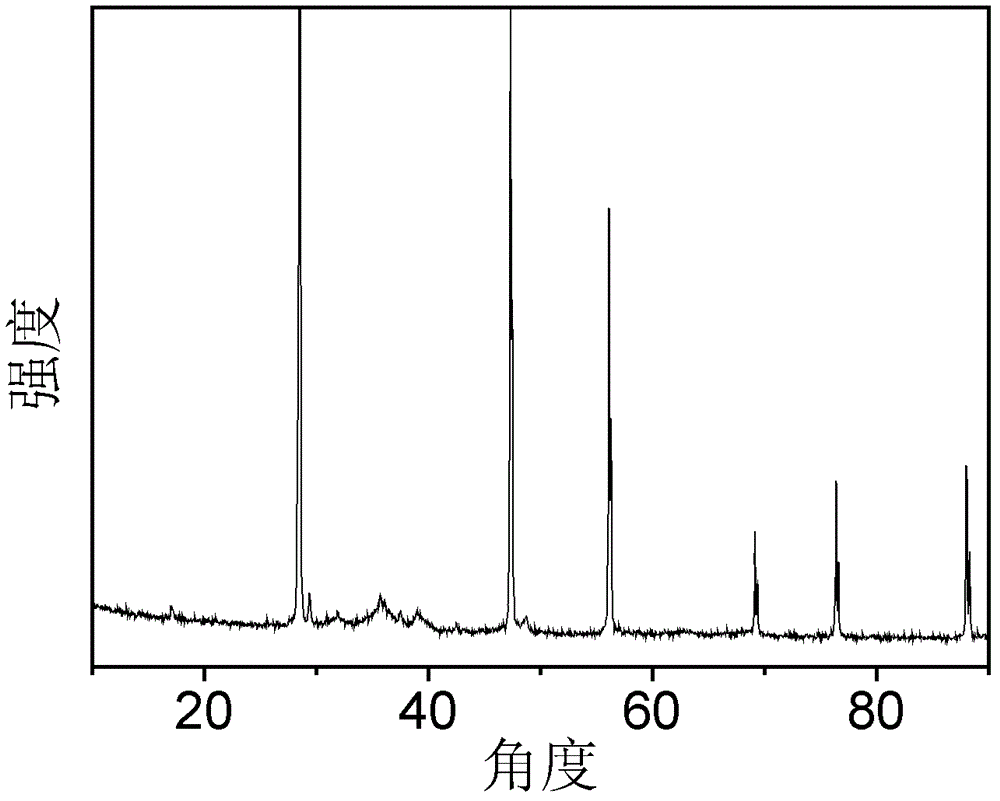

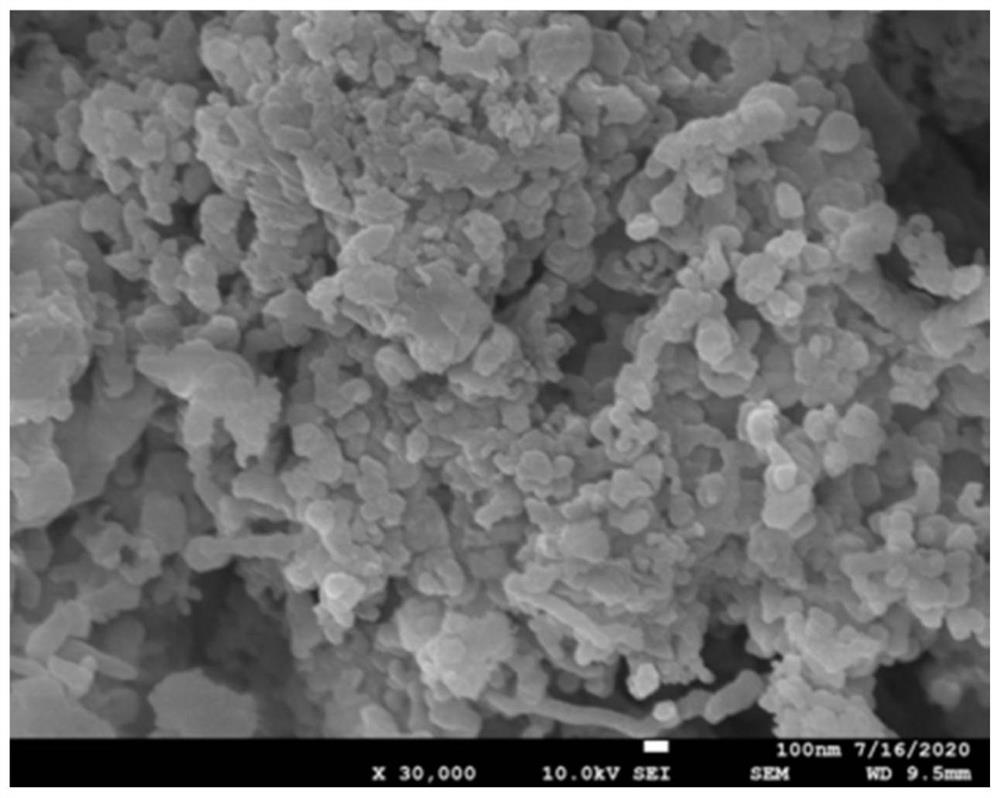

Application of waste contact as lithium ion battery negative material

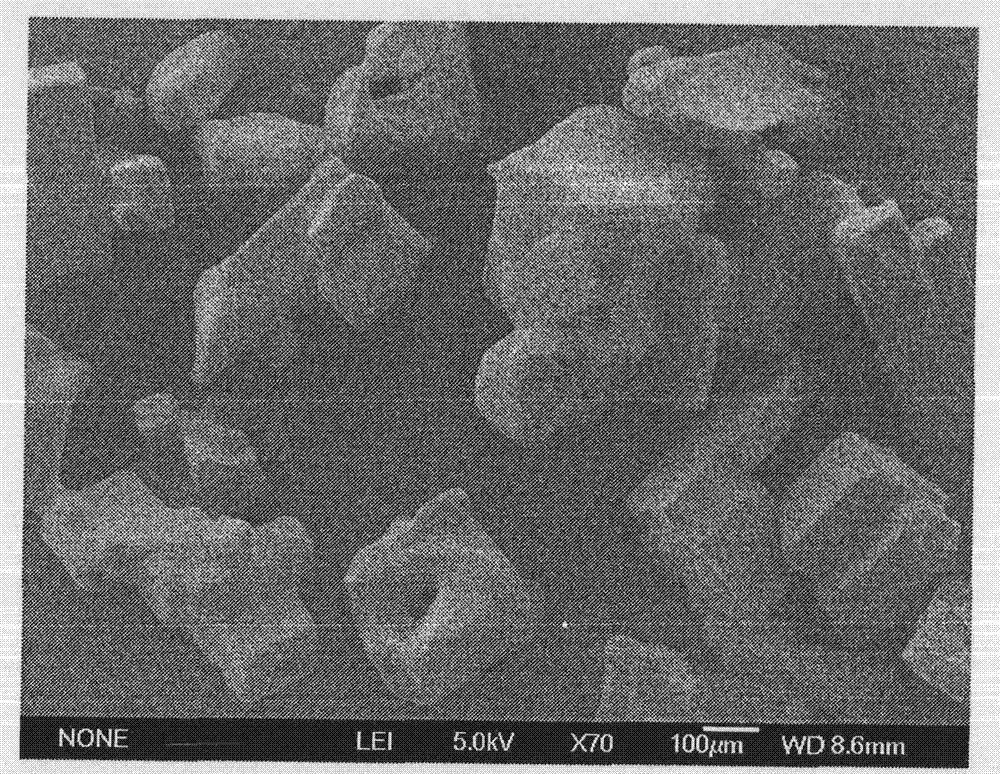

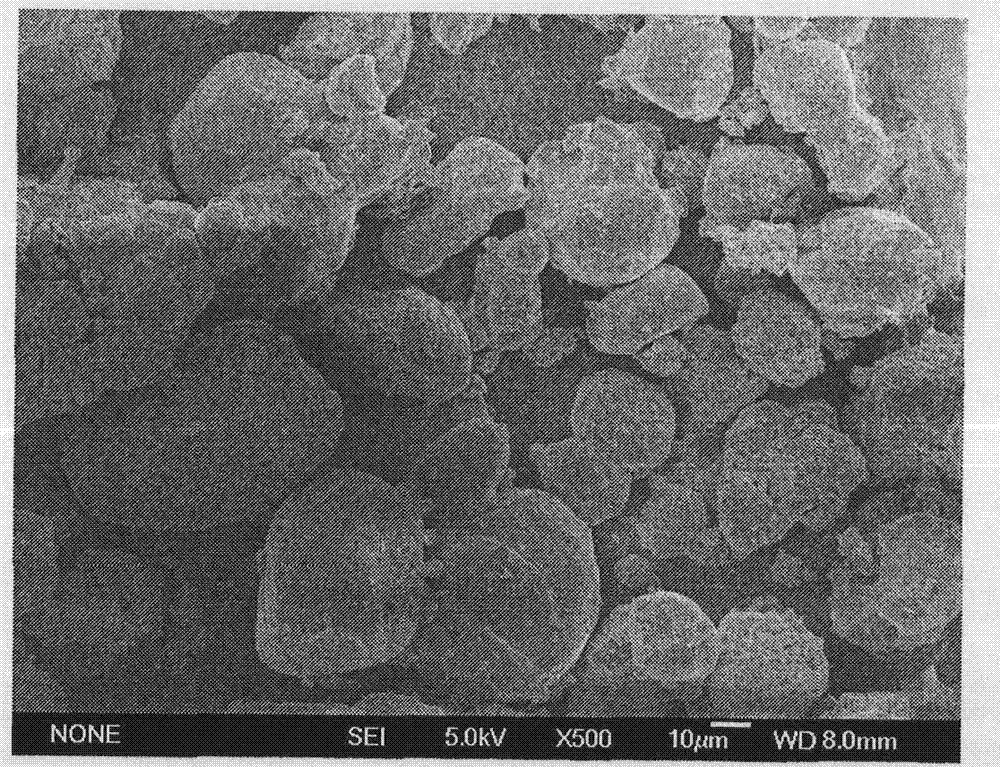

ActiveCN102637920ALow costThe modification method is simpleCell electrodesWaste accumulators reclaimingAcid washingCopper

The invention relates to the field of battery materials, in particular to application of waste contact generated in a methyl chlorosilane preparation process as a lithium ion battery negative material. The waste contact is a silicon-based porous composite material, mainly comprises components of elementary substances, such as silicon, carbon and copper and further comprises trace metal elements such as zinc, iron, aluminum and tin. According to the invention, the waste contact is modified by the steps of acid washing, oxidizing, reducing, pyrolyzing, thermal treating and the like so as to improve the electrochemical performance, thereby finally obtaining the silicon-based porous composite material capable of serving as the lithium ion battery negative material. The silicon-based porous composite material has the advantages of low cost, simpleness in the modification method, high charging / discharging capacitiy and good cycle performance, and is suitable for the lithium ion battery negative material; in addition, the solid waste contact generated in an organic silicon synthesis industrial process is utilized to create high value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Modified slag powder and preparation method thereof

ActiveCN104761160AExpand application channelsImprove performance indicatorsSolid waste managementCement productionHot blastGypsum

The invention relates to a modified slag powder and a preparation method thereof. The preparation method comprises the following steps: performing heat treatment on the silico-calcium slag to obtain the heat-treated silico-calcium slag; mixing the heat-treated silico-calcium slag with coal ash, slag, gypsum, a cement grinding aid and an additive and grinding to obtain the modified slag powder. According to the preparation method, the silico-calcium slag powder is prepared by use of the silico-calcium slag by-product of producing alumina from the coal ash, and therefore, the application ways of the silico-calcium slag are expanded and the performance indices such as the strength of the concrete can be improved; on the other hand, the modified slag powder prepared by use of the method is superior to common blast furnace slag powder in both early strength and long-term strength, and the various indices at least conform to the standards of the national S95 grade slag powder, and therefore, the modified slag powder can be used as a cement or concrete admixture; the production operation process of the modified slag powder is simple and convenient and the problems of consumption and high value utilization of the silico-calcium slag can be effectively solved; in short, the modified slag powder has great popularization and application value.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Method for producing amino acid fertilizer from soybean meal through solid-state fermentation

InactiveCN104557154ASolve the difficult to degradeSolve the problem of high value utilizationNitrogenous fertilisersBiotechnologyNutrition

The invention relates to a method for producing amino acid fertilizer from soybean meal through solid-state fermentation comprises the following processing steps: uniformly mixing soybean meal with nutritional supplements in a ratio of 1:(0.8-1.5), wherein initial PH is 7.0-7.5; sterilizing, inoculating bacillus and actinomycetes to form complex microbial inoculants, and carrying out solid-state fermentation, wherein inoculum sizes of bacillus and actinomycetes are 5-10% and 4-10% respectively, and turning over 1-2 times everyday during fermentation; stopping fermentation after the solid-state fermentation is carried out for 8-12 days, extracting fermented material with water for 0.5-1 hour according to a ratio of material to water of 1:(10-15); after extraction is finished, filtering by virtue of 200-mesh boulting cloth for separating insoluble substances; and concentrating filtrate to a certain concentration, carrying out spray drying and split charging. The method for producing the amino acid fertilizer from the soybean meal through solid-state fermentation has the advantages of mild reaction conditions, complete degradation, no pollution, low energy consumption, low production cost, formation of disease-resistant substances and the like, and the prepared amino acid fertilizer is of a total dissolution type.

Owner:OCEAN UNIV OF CHINA

Catalyst for preparing formate from CO2 and preparation method thereof

ActiveCN102794179ASimple processReduce manufacturing costOrganic compound preparationCarboxylic acid esters preparationChemical industryOrganic solvent

The invention relates to the field of chemical industry production of formate from CO2, particularly a catalyst for preparing formate from CO2 and a preparation method thereof. The method for preparing the catalyst for preparing formate from CO2-containing synthetic gas, which is a spent contact mass generated in an organosilicon monomer methyl chlorosilane production process, comprises the following steps: washing the spent contact mass with an organic solvent, filtering, roasting, dissolving with acid, precipitating with alkali, filtering, drying and calcining. The invention solves the problem of high-value comprehensive utilization of solid residue spent contact mass in organosilicon synthesis industry. The prepared catalyst for preparing formate from CO2-containing synthetic gas has the advantages of low raw material cost and simple operational method, and can easily implement large-scale production; and the catalyst provided by the invention has higher formate synthesis activity, higher heat stability and better reproducibility, and is beneficial to controlling the product quality.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing desalinated protein powder through efficient desalination and drying of salted egg white

The invention relates to a method for preparing desalinated protein powder through efficient desalination and drying of salted egg white, belonging to the technical field of deep processing of by-products of eggs. The method comprises the following steps: by-product salted egg white generated in salted egg yolk production is taken as a raw material and then is filtered, water is added and mixed with the filtered salted egg white, and ultrasonic wave and vacuum infiltration are carried out on the mixture for combined desalination treatment, so as to prepare the efficient, quality-assured, desalinated ultrafine egg white powder through low-temperature crushing, microwave freeze-drying and negative pressure microwave spouted bed drying by combination of drying and ultrafine pulverization technology, and the ultrafine egg white powder is applied to produce high protein noodles. The method has the advantages that through the combined treatment of the ultrasonic wave and vacuum infiltration, the desalination rate of the salted egg white reaches 95-98%; after combined drying by use of the microwave freeze-drying and the negative pressure spouted bed drying, the color change degree of thedesalinated egg white powder is within 3%, and the whiteness of the desalinated egg white powder reaches 88-91%. Then, the ultrafine pulverization is carried out, so that the granularity reaches 30-50mum, and the aim that the production of the desalinated salted egg white powder is efficient and quality-assured is achieved.

Owner:JIANGNAN UNIV +1

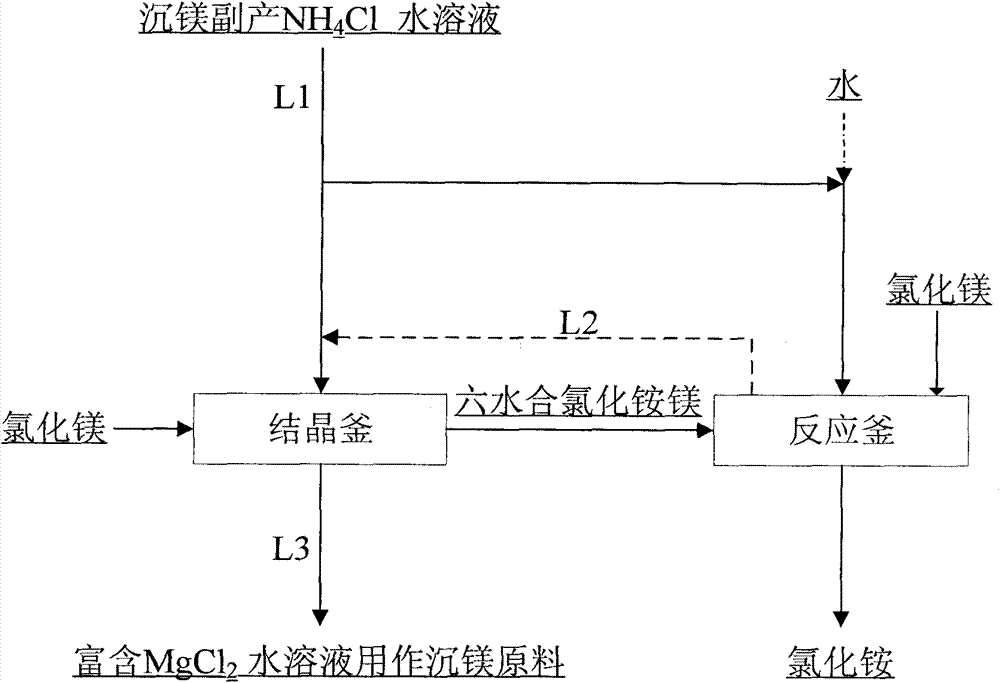

Method for recovering ammonium chloride by preparing complex salt of magnesium ammonium chloride hexahydrate

InactiveCN102145901BFacilitates the integration of production processesSimple methodChloride preparationAmmonium halidesChlorideAqueous solution

The invention relates to a method for recovering ammonium chloride by preparing complex salt of magnesium ammonium chloride hexahydrate (HH4MgC13 6H2O). The method comprises the following steps of: placing aqueous solution of ammonium chloride into a crystallizing kettle; regulating the pH of the solution to 4 to 6 by hydrochloric acid; controlling the temperature of the crystallizing kettle in the range of 10 to 80 DEG C; adding magnesium chloride into the crystallizing kettle under the stirring condition, stopping adding the magnesium chloride when the concentration of the magnesium chloride in the solution reaches 3 to 5mol / L and then continuously stirring for 30 to 120 minutes; drying filtered solid to obtain magnesium ammonium chloride hexahydrate; and decomposing the magnesium ammonium chloride hexahydrate at a lower temperature of 0 to 50 DEG C to obtain solid of ammonium chloride. With the adoption of the method, no waste liquid is discharged in the whole process, and an ammonium chloride recovery process and a magnesium precipitating process are well integrated. The method has strong operability and is easy to realize industrialization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Drainage anti-blocking device special for kitchen sink

InactiveCN110886352AAvoid cleaning hassleSolve health problemsDomestic plumbingEnvironmental engineeringFeed processing

The invention discloses a drainage anti-blocking device special for kitchen sinks, and belongs to the field of garbage cleaning devices. The drainage anti-blocking device comprises a sliding slottingmechanism, wherein the sliding slotting mechanism comprises a sliding groove body, a fixing head, a pull rod and a control handle, a garbage groove is formed in the space in the sliding groove body, and a drainage discharging device is arranged at the lower part of the garbage groove. According to the drainage anti-blocking device, the sliding type double-station garbage groove is adopted to holdand collect garbage, the trouble of manual re-cleaning is avoided, garbage in the groove can be easily cleaned through the control handle, and convenience and rapidness are achieved. The solid kitchenwaste in the water tank after adopting the drainage anti-blocking device can be discharged in time and collected in a centralized manner, the liquid in the kitchen waste is reduced to escape everywhere, the peculiar smell is greatly reduced, and the separated solid kitchen waste can be widely applied to feed processing and field returning fertilization after being refined and collected, so that the problem of sanitary problem and high-value utilization of kitchen waste is solved.

Owner:HUNAN UNIV OF TECH

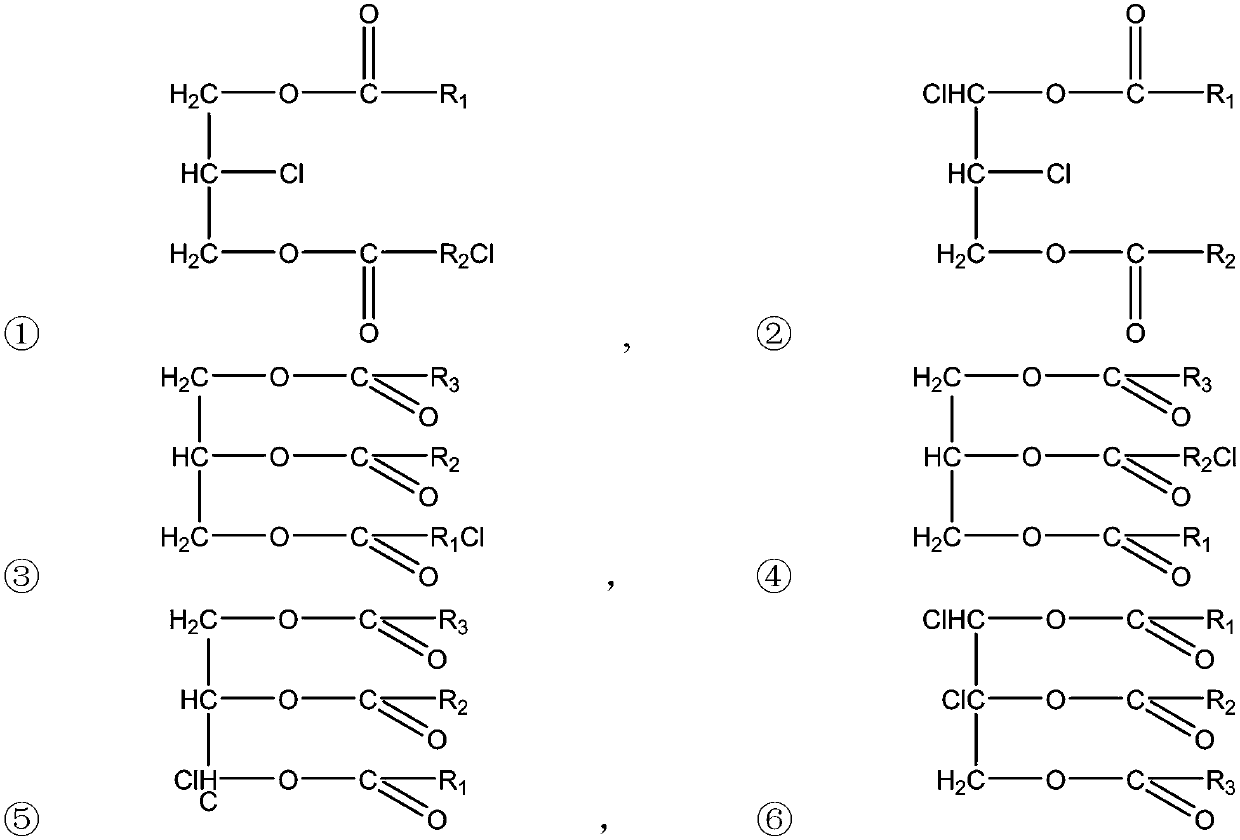

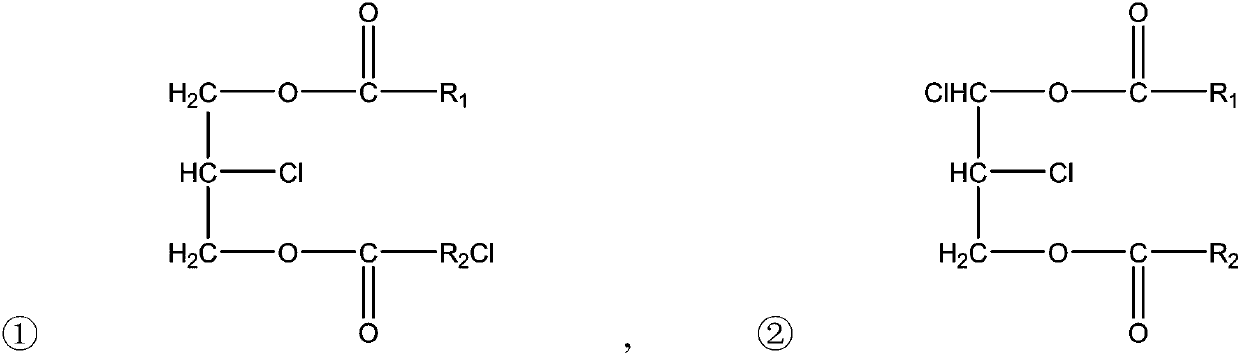

Composite plasticizer taking chlorinated glycerol ester as main body as well as preparation method and application thereof

InactiveCN107778878AIncrease added valueIncrease the chlor-alkali industry chainBenzoic acidBiodiesel

The invention relates to a composite plasticizer taking chlorinated glycerol ester as a main body. The composite plasticizer comprises: a combination of any three or more of formula (1) to formula (6), wherein R1, R2 and R3 represent H, and C1-C5 alkyl or phenyl respectively; 3 weight percent of a stabilizer, 0.5 weight percent of a surfactant and 5-10 weight percent of a viscosity reducer. The invention also provides a preparation method of the composite plasticizer, and the preparation method comprises reacting a biodiesel byproduct namely crude glycerol, alkyl acid or benzoic acid, a water-carrying agent, and an esterification catalyst, and other steps. The plasticizing efficiency of the composite plasticizer provided by the invention can be equivalent to that of dioctyl phthalate (DOP); moreover, the biodiesel byproduct namely crude glycerol is fully utilized, and direct high-value utilization with a high transformation rate of the crude glycerol and the problem that a large numberof byproducts cannot be treated are fundamentally solved at the same time; on the other hand, chlorine can also be utilized to increase the chlorine-alkali industry chain and increase economic benefits; the preparation process of the composite plasticizer is simple and reliable, and a produced plasticizer product is stable in chemical property and good in product processing property, avoids potential dangers at the same time, and is safe and environment-friendly.

Owner:SHANDONG YANHAI CONSTR RESOURCES

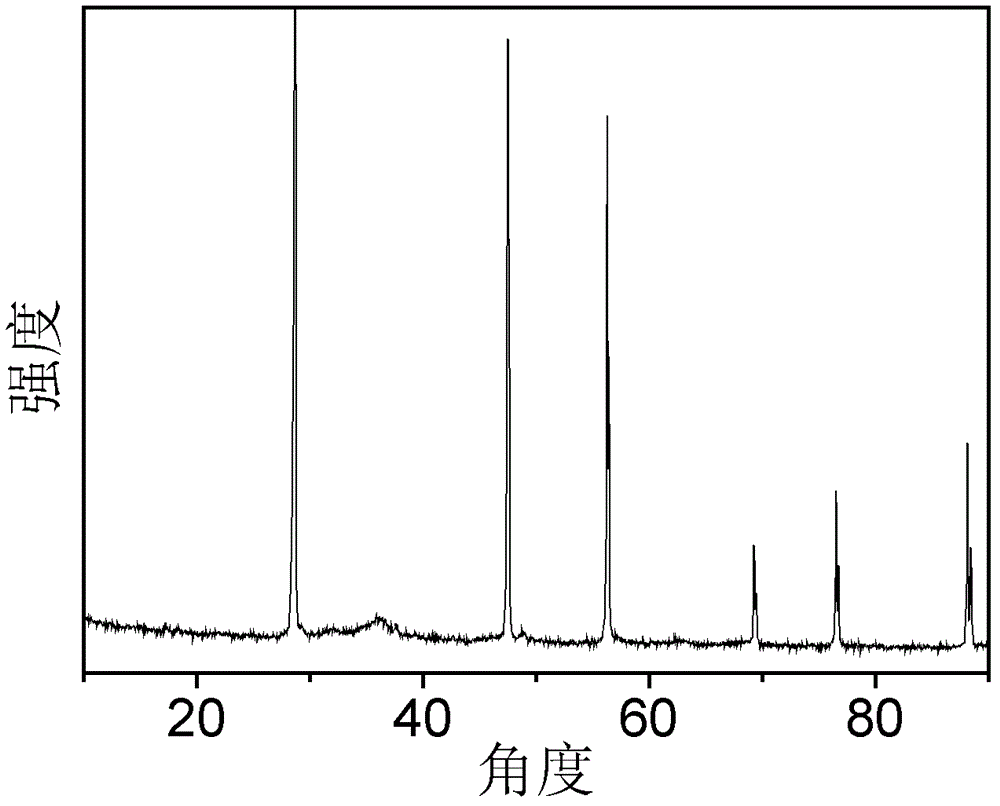

Application of waste contact as lithium ion battery negative material

ActiveCN102637920BSolve the problem of high value utilizationLow costCell electrodesWaste accumulators reclaimingAcid washingCopper

The invention relates to the field of battery materials, in particular to application of waste contact generated in a methyl chlorosilane preparation process as a lithium ion battery negative material. The waste contact is a silicon-based porous composite material, mainly comprises components of elementary substances, such as silicon, carbon and copper and further comprises trace metal elements such as zinc, iron, aluminum and tin. According to the invention, the waste contact is modified by the steps of acid washing, oxidizing, reducing, pyrolyzing, thermal treating and the like so as to improve the electrochemical performance, thereby finally obtaining the silicon-based porous composite material capable of serving as the lithium ion battery negative material. The silicon-based porous composite material has the advantages of low cost, simpleness in the modification method, high charging / discharging capacitiy and good cycle performance, and is suitable for the lithium ion battery negative material; in addition, the solid waste contact generated in an organic silicon synthesis industrial process is utilized to create high value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A kind of preparation method of soil conditioner using phosphogypsum as raw material

ActiveCN105001872BRealize resource utilizationLarge specific surface areaAgriculture tools and machinesOther chemical processesResource utilizationPhosphogypsum

The invention discloses a preparation method of a soil conditioner taking phosphogypsum as a raw material, and belongs to the technical field of phosphogypsum resource utilization. The preparation method comprises the steps of smashing the raw material, namely the phosphogypsum, and mixing with wet-process activated carbon evenly according to a certain ratio, then adding ammonium hydroxide or ammonia-nitrogen wastewater to carry out an acid-base neutralization reaction, obtaining a solid product and filter liquor after performing solid-liquid separation on a reactant, and drying the solid product to obtain the soil conditioner. The obtained soil conditioner is charcoal grey and in the shape of amorphous wet powder particle, has flexibility and elasticity, has no dust, has high specific surface area and high adsorptive property, and meanwhile, contains multiple nutritional ingredients required by the growth of crops, wherein ammonium hydrogen phosphate and ammonium dihydrogen phosphate have the capabilities of adjusting and stabilizing the pH value. The soil conditioner strengthens the capability of conditioning soil, increases the storage property, and really has eurytopicity, specificity, versatility, environmental protection property and economy.

Owner:赵常然

A kind of preparation method of modified slag powder

ActiveCN104761160BExpand application channelsHigh strengthSolid waste managementCement productionSlagCement grinding

The invention relates to a modified slag powder and a preparation method thereof. The preparation method comprises the following steps: performing heat treatment on the silico-calcium slag to obtain the heat-treated silico-calcium slag; mixing the heat-treated silico-calcium slag with coal ash, slag, gypsum, a cement grinding aid and an additive and grinding to obtain the modified slag powder. According to the preparation method, the silico-calcium slag powder is prepared by use of the silico-calcium slag by-product of producing alumina from the coal ash, and therefore, the application ways of the silico-calcium slag are expanded and the performance indices such as the strength of the concrete can be improved; on the other hand, the modified slag powder prepared by use of the method is superior to common blast furnace slag powder in both early strength and long-term strength, and the various indices at least conform to the standards of the national S95 grade slag powder, and therefore, the modified slag powder can be used as a cement or concrete admixture; the production operation process of the modified slag powder is simple and convenient and the problems of consumption and high value utilization of the silico-calcium slag can be effectively solved; in short, the modified slag powder has great popularization and application value.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Catalyst for low-temperature synthesis of methanol and preparation method

ActiveCN102773102BSolve the problem of high value utilizationLow costOrganic compound preparationHydroxy compound preparationReduction treatmentOrganic solvent

The invention relates to the production field of low-temperature synthesis of methanol, and particularly relates to a catalyst for low-temperature synthesis of methanol and a preparation method. The method includes the steps of: crushing and screening waste contacts generated from direct method production of methyl chlorosilane, and then using an organic solvent for cleaning. The method also can further include the following steps of: subjecting the cleaned waste contacts to one or more of an oxidation treatment, a reduction treatment and a heat treatment, thus obtaining the catalyst for low-temperature preparation of methanol from synthesis gas. The method provided in the invention solves the high value comprehensive utilization problem of solid residual waste contacts in the organosilicon synthesis industry. The prepared catalyst has the advantages of low raw material cost, simple operation method, as well as easy large-scale production, and shows higher methanol synthesis activity and thermal stability.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

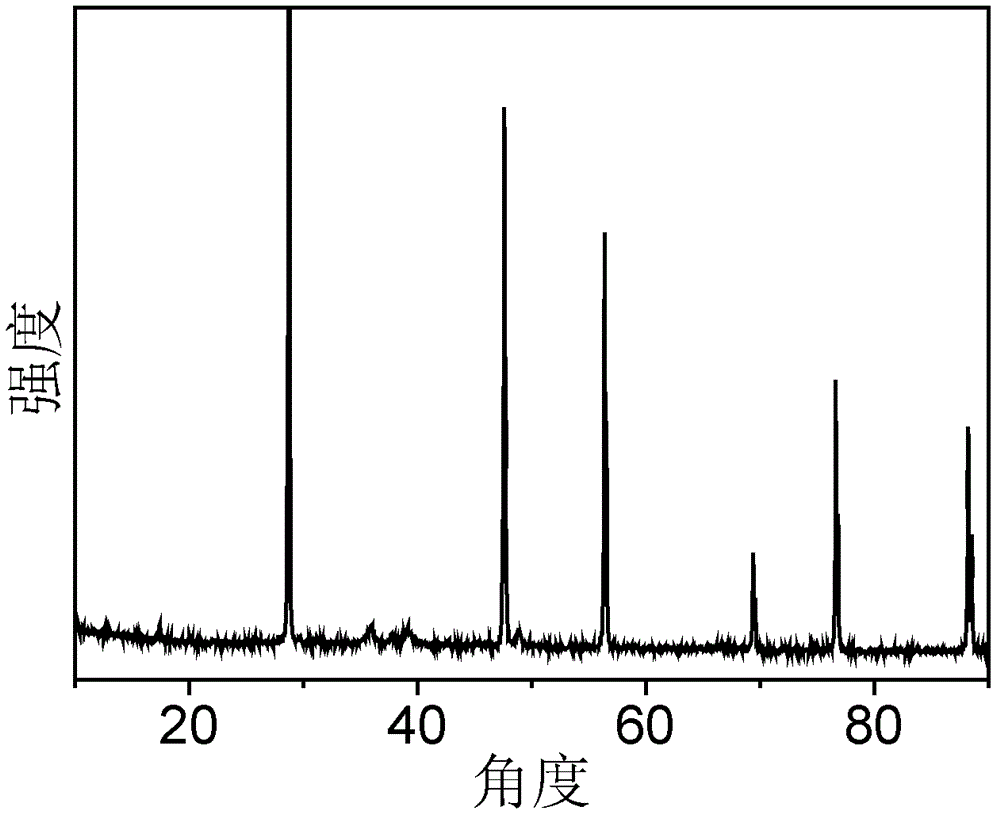

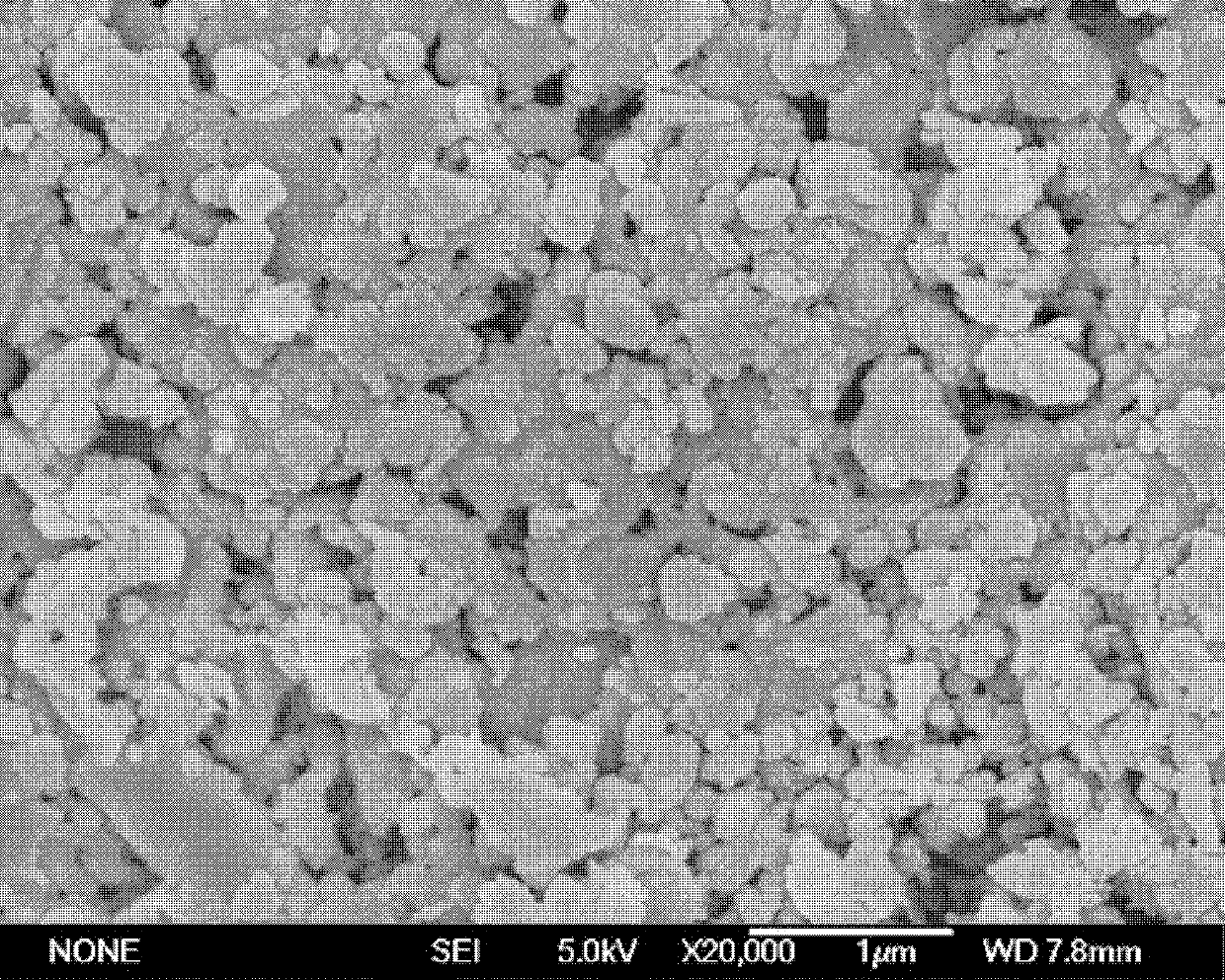

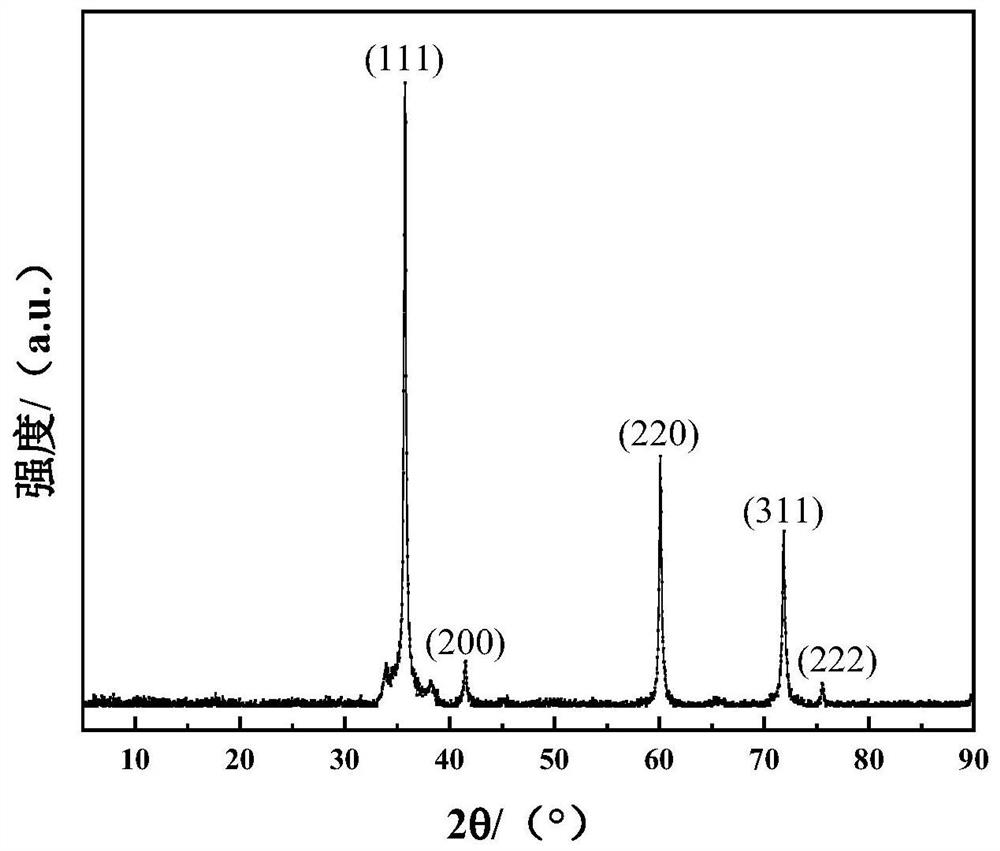

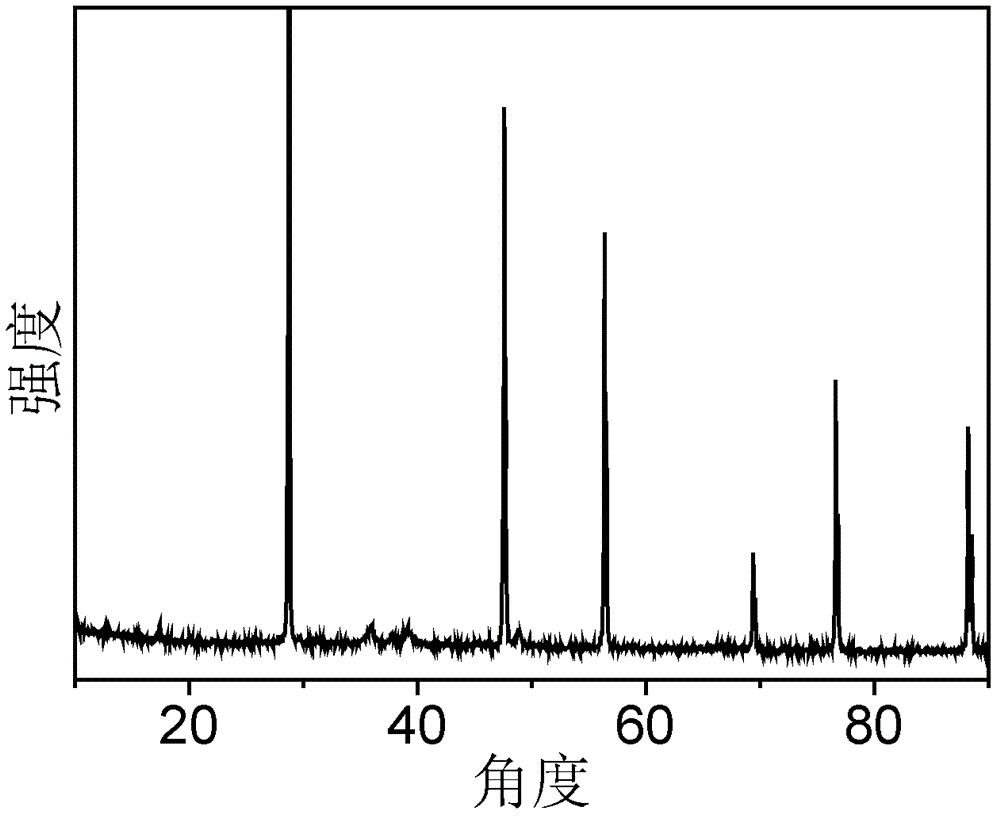

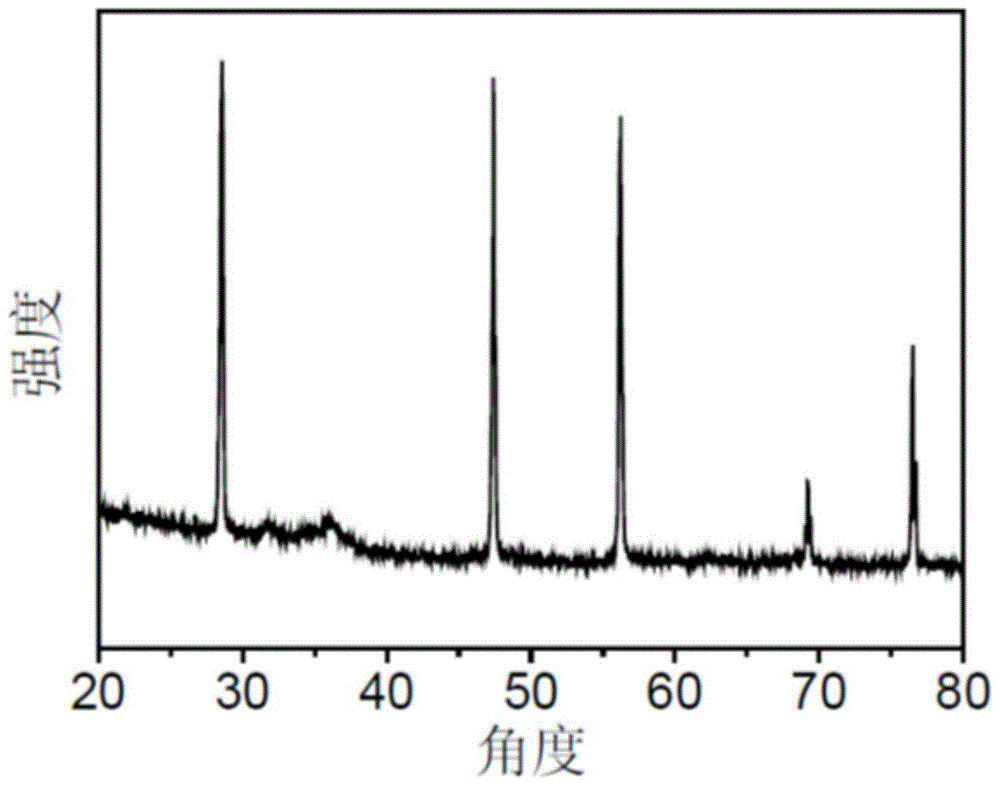

Preparation method of silicon carbide

PendingCN114149007ALow cost of preparationSolve the problem of high value utilizationSilicon carbideCarbide siliconWaste tires

The invention relates to a preparation method of silicon carbide, which comprises the following steps: (1) mixing tire semicoke with quartz sand to obtain a mixture; (2) carrying out heat treatment synthesis on the mixture obtained in the step (1) under a protective atmosphere to obtain a crude product; and (3) roasting the crude product obtained in the step (2) to obtain the silicon carbide product. The silicon carbide is prepared from the tire semicoke and the quartz sand through a specific preparation method, the purity of the obtained silicon carbide is high, the preparation cost of the silicon carbide is reduced, the problem of high-value utilization of the waste tire semicoke is solved, the raw material cost is low, the yield of the silicon carbide is high, the preparation process is simple, and industrialization is easy to realize.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

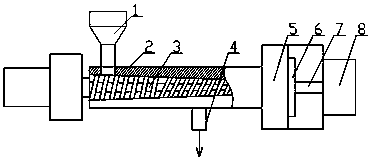

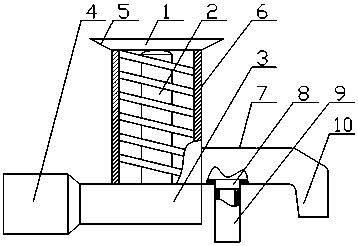

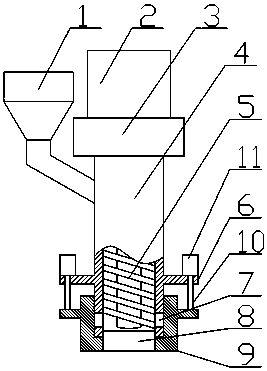

Kitchen waste particle preparation device

InactiveCN110901138ASolve health problemsSolve the problem of high value utilizationMetal working apparatusShaping pressEnvironmental engineeringFeed processing

The invention provides a kitchen waste particle preparation device. The device comprises a hopper for discharging and a barrel connected with the hopper; a pair of conical screws meshed with each other is arranged in the barrel; a water outlet is formed in the side wall of the barrel; a heater is arranged outside the barrel; the tail end of the barrel is connected with a granulating die head; a plurality of granulating holes are formed in the granulating die head; and a cutter is arranged at the discharging hole of the granulating die head. According to the kitchen waste particle preparation device of the invention, high-temperature kitchen waste is subjected to high-pressure extrusion by means of a miniature different-direction double-screw extruder, and drying and granulation are carriedout by a high-compression feeding extrusion dehumidification and heating dehumidification combined method; prepared kitchen waste particles are compact in texture and smooth in surface. The device can be widely applied to feed processing and kitchen waste-based field fertilization. With the device adopted, the sanitation problem and high-valued utilization problem of kitchen waste can be solved.

Owner:HUNAN UNIV OF TECH

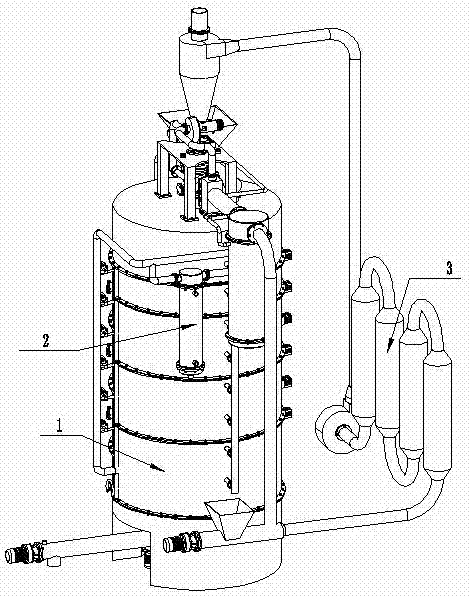

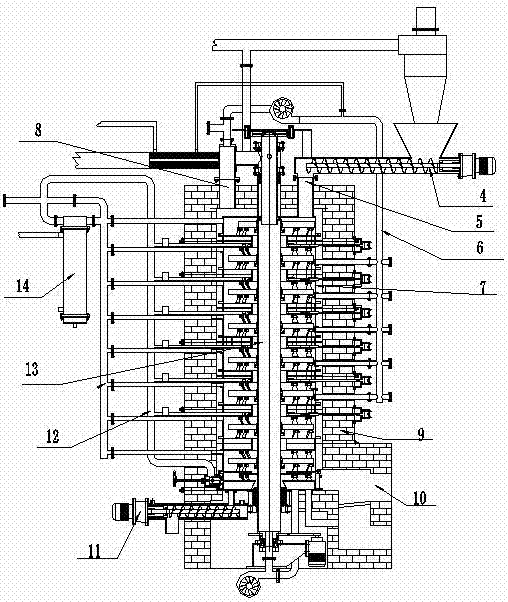

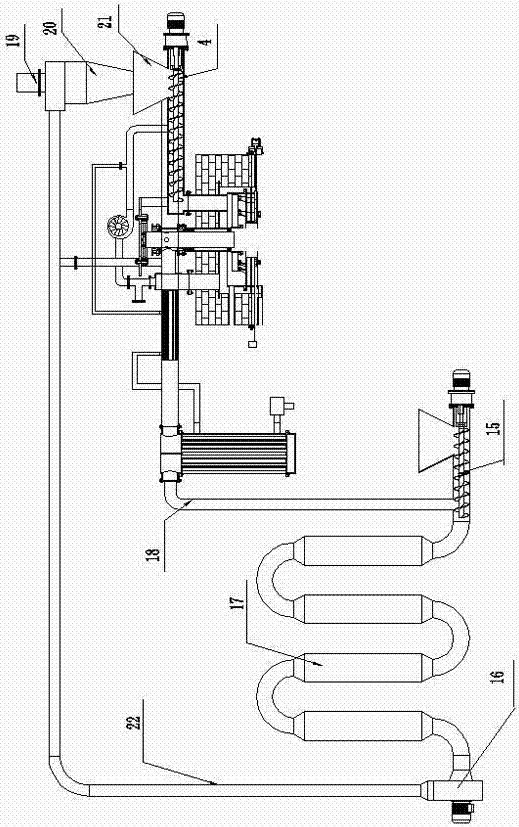

A system for producing activated carbon from straw

A system for producing activated carbon from straw, including a fried activated carbon furnace, a straw feeding system and a flue gas air activator delivery system. The straw feeding system includes a straw drying room, and a drying induced draft fan is installed at the discharge end , the feeding end is equipped with a broken straw screw propeller and a flue gas inlet pipe connected to the flue gas main pipe of the frying-type activated carbon furnace, and the discharge pipe provides dried straw for the frying-type activated carbon furnace through the cyclone dust collector; The above-mentioned flue gas air activator delivery system transports part of the flue gas discharged from the frying activated carbon furnace and the superheated steam generated by the system to the material frying and mixing chamber in the furnace section through the flue gas compressor. The production process is simplified and purified, the energy consumption is greatly reduced, and the product yield and product quality are improved.

Owner:LIANYUNGANG MINGJING BIOLOGICAL ENERGY CO LTD

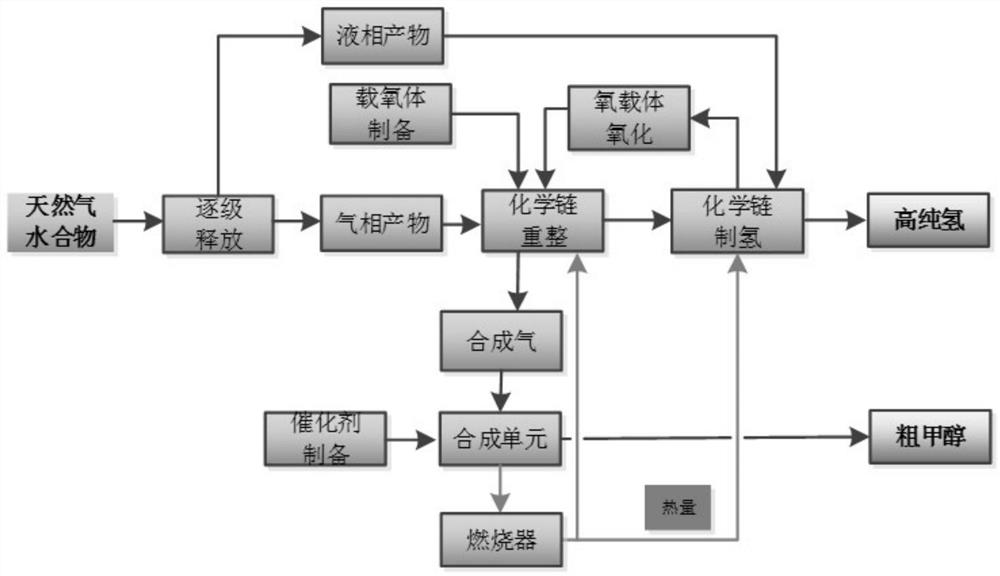

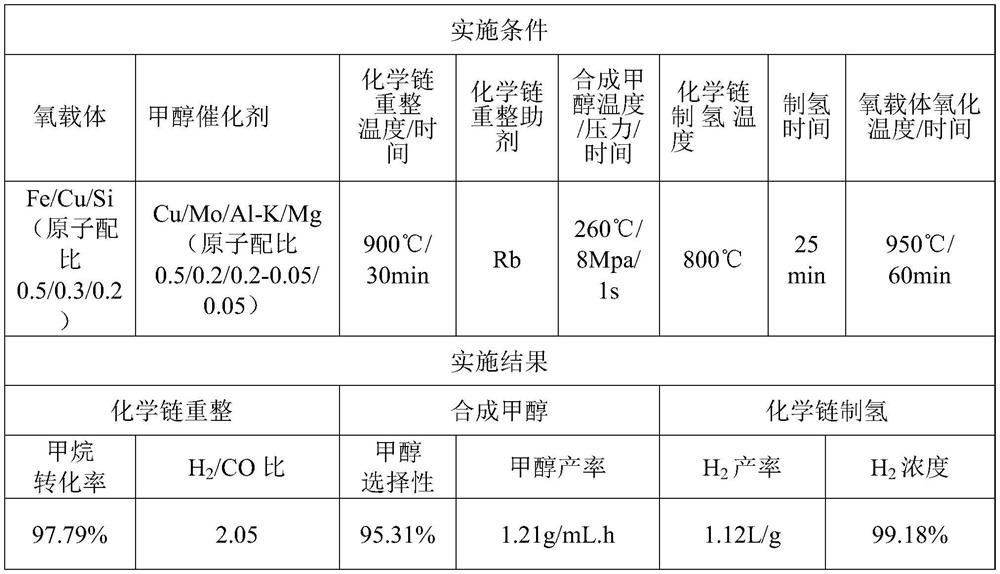

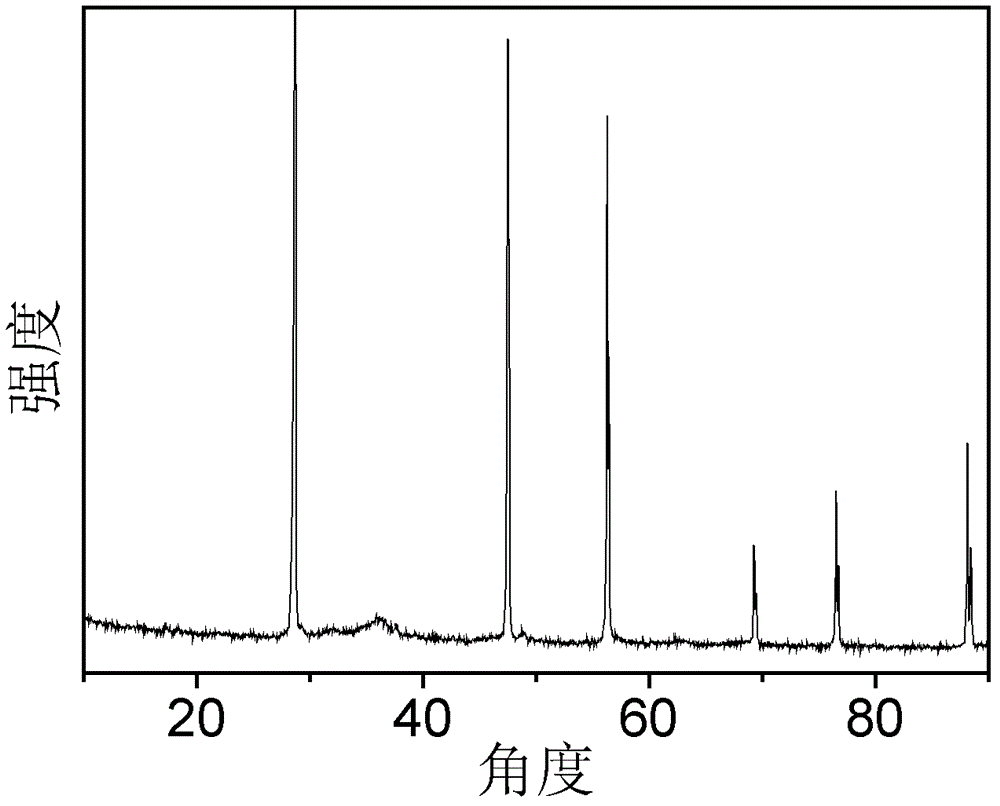

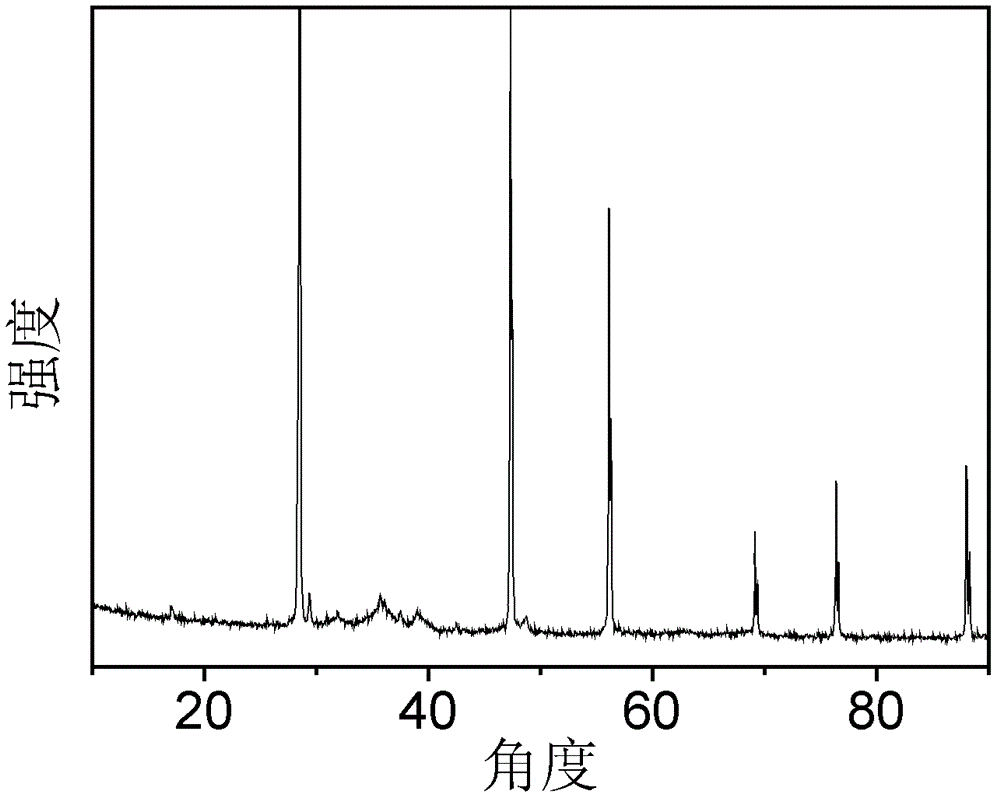

Method for co-producing alcohol and hydrogen through chemical chain conversion of natural gas hydrate

PendingCN114716300ASolve the problem of high value utilizationSimple and fast operationOrganic compound preparationCatalyst regeneration/reactivationAlcoholProcess engineering

The invention discloses a method for co-producing alcohol and hydrogen through chemical chain conversion of natural gas hydrate. According to the method, gas and liquid two-phase composition of the natural gas hydrate is converted into methanol and high-purity hydrogen through the steps of oxygen carrier preparation, chemical looping reforming, methanol synthesis, chemical looping hydrogen production, oxygen carrier regeneration and the like, high-value utilization of the natural gas hydrate is achieved, and the comprehensive utilization efficiency of resources is high. The technology does not need an oxidizing medium preparation process in the traditional methanol synthesis process, has the advantages of simple process, low cost, cleanness, environmental protection and good economic benefit of the product, partially solves the problem that the traditional natural gas hydrate is difficult to store and transport, and has a wide application prospect.

Owner:GUANGDONG LAB OF SOUTHERN OCEAN SCI & ENG GUANGZHOU +1

Catalyst for preparing formate from CO2 and preparation method thereof

ActiveCN102794179BSolve the problem of high value utilizationLow costOrganic compound preparationCarboxylic acid esters preparationChemical industryOrganic solvent

The invention relates to the field of chemical industry production of formate from CO2, particularly a catalyst for preparing formate from CO2 and a preparation method thereof. The method for preparing the catalyst for preparing formate from CO2-containing synthetic gas, which is a spent contact mass generated in an organosilicon monomer methyl chlorosilane production process, comprises the following steps: washing the spent contact mass with an organic solvent, filtering, roasting, dissolving with acid, precipitating with alkali, filtering, drying and calcining. The invention solves the problem of high-value comprehensive utilization of solid residue spent contact mass in organosilicon synthesis industry. The prepared catalyst for preparing formate from CO2-containing synthetic gas has the advantages of low raw material cost and simple operational method, and can easily implement large-scale production; and the catalyst provided by the invention has higher formate synthesis activity, higher heat stability and better reproducibility, and is beneficial to controlling the product quality.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

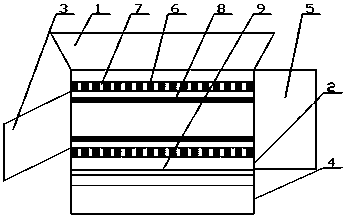

Electric anti-blocking drainage device for kitchen

InactiveCN110886353ASolve health problemsSolve the problem of high value utilizationDomestic plumbingEnvironmental engineeringRefuse Disposals

The invention discloses an electric anti-blocking drainage device for a kitchen, and belongs to the field of garbage clearing devices. The electric anti-blocking drainage device comprises a cylinder body, wherein the cylinder body is provided with a material extruding mechanism and communicates with a discharging pipe for drainage and discharging materials. According to the device, kitchen waste is conveyed, compressed and dehydrated through adopting a single screw, and the water-solid waste mixture is quickly converted into dry solid waste. The processed kitchen waste is dry in texture and iscollected in a centralized manner, thus reducing the escape of liquid in the kitchen waste, and greatly reducing peculiar smell. The dry kitchen waste can be widely applied to feed processing and field returning fertilization, thus solving the problems of sanitation and high-value utilization of the kitchen waste.

Owner:HUNAN UNIV OF TECH

Portable kitchen garbage granulating device

InactiveCN110917994ASolve health problemsSolve the problem of high value utilizationGranulation by pressingProcess engineeringFeed processing

The invention provides a portable kitchen garbage granulating device comprising a hopper and a cylinder body connected with the hopper. The cylinder body is internally provided with a pair of formingroller and pressing roller which synchronously rotate in different directions. A plurality of granulating holes are formed in the forming roller, the inner cavity of the forming roller is communicatedwith a discharging opening, and a material blocking rod is arranged in the inner cavity. A filter screen is arranged below the forming roller and the pressing roller. A drainage groove connected withthe cylinder body is formed below the filter screen. The kitchen garbage is extruded and dehydrated by adopting a double-roller structure, the solid garbage is forcibly pressed into granulating holesof the forming roller through the pressing roller to form continuous garbage strips, and the continuous garbage strips are cut off through the material blocking rod installed in the forming roller tobe manufactured into solid strips or particles with compact structures. The prepared kitchen waste strips or particles are smooth in surface and uniform in density and can be widely applied to feed processing and returning to fields for fertilization so that the sanitation problem and the high-valued utilization problem of kitchen waste can be solved.

Owner:HUNAN UNIV OF TECH

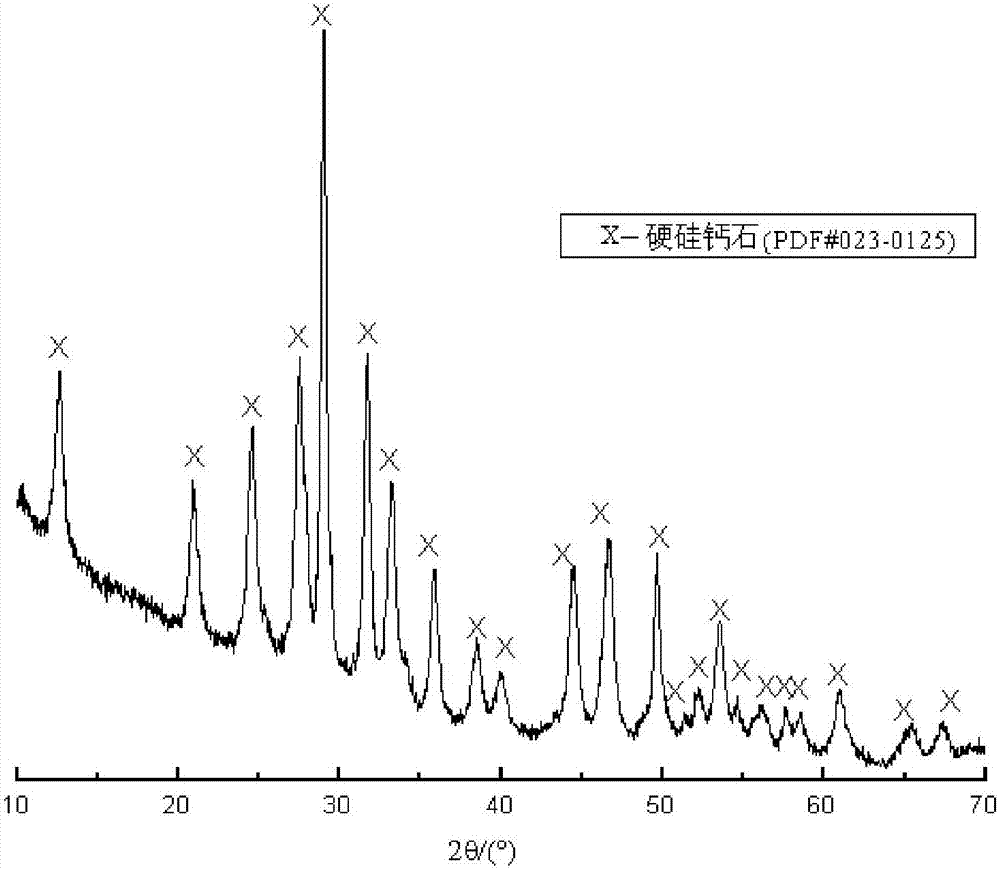

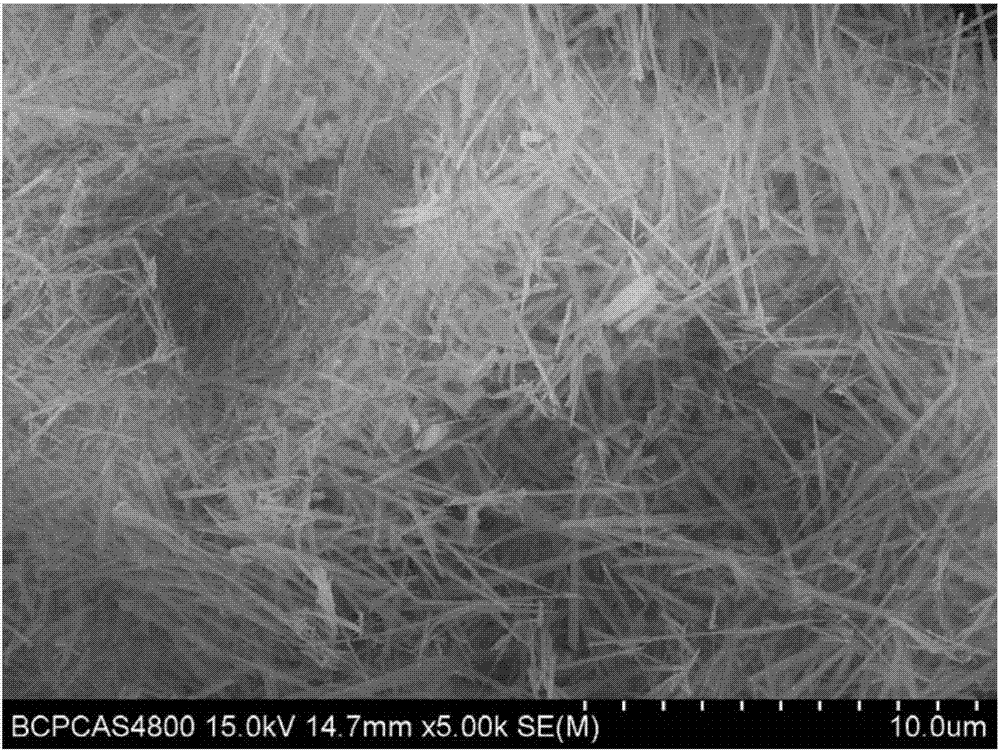

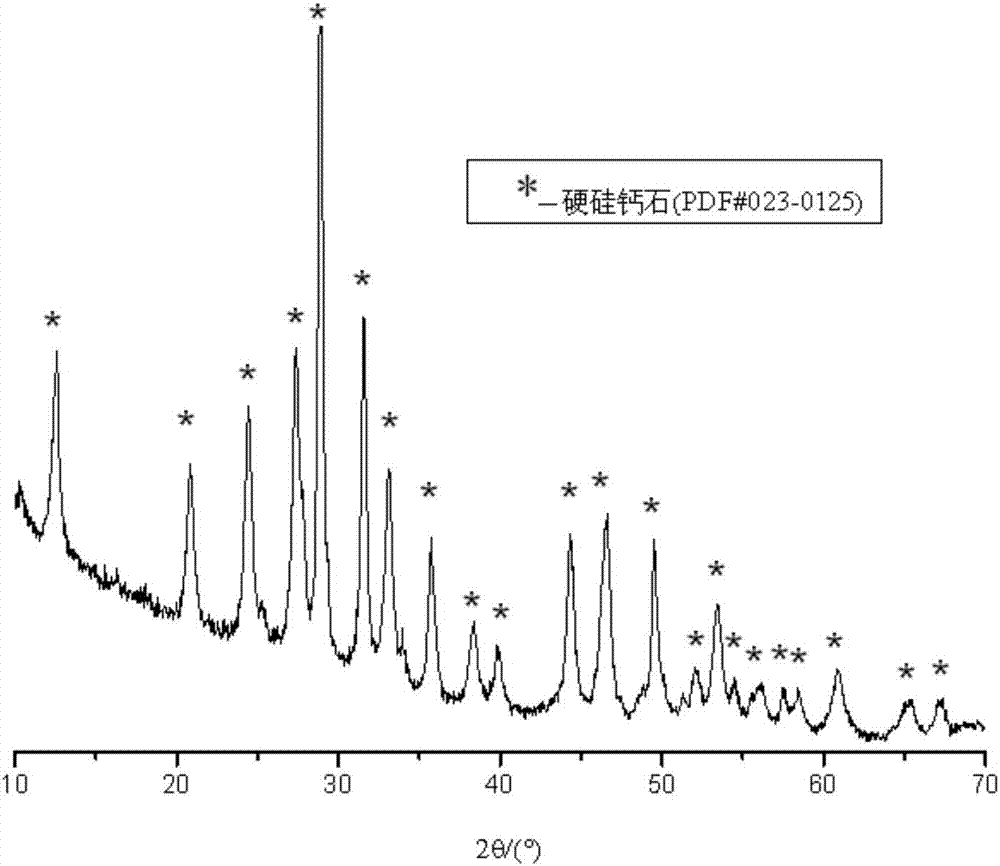

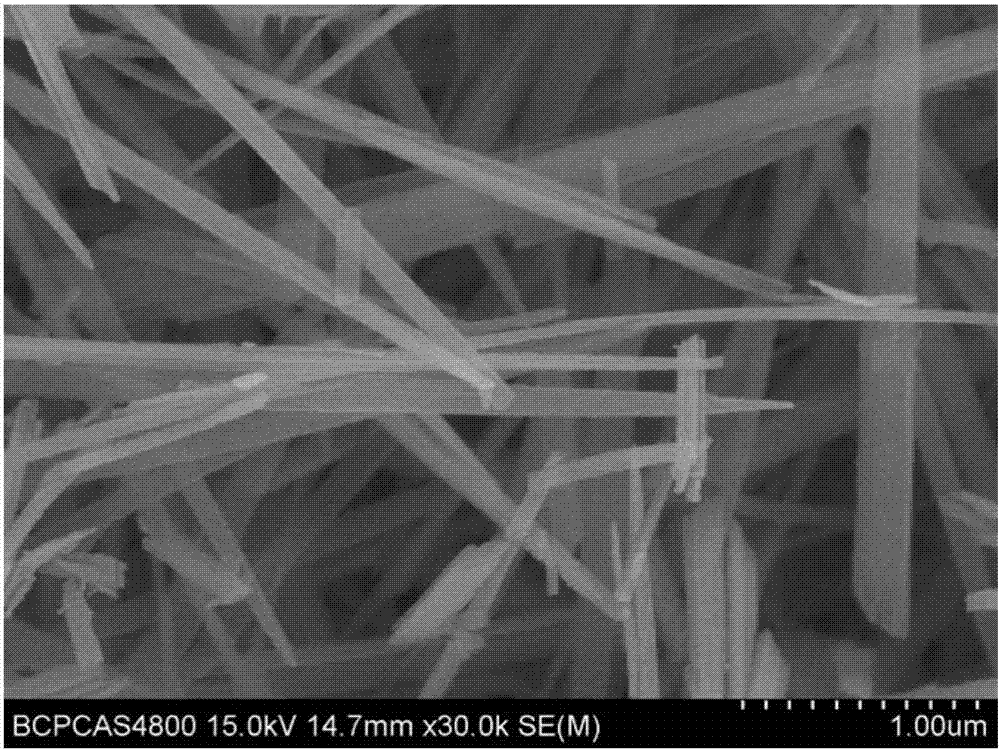

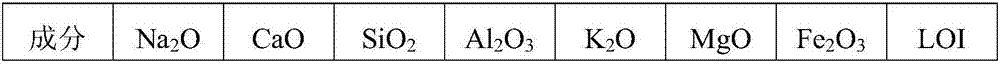

A kind of method that utilizes disodium calcium silicate to prepare xonotlite

ActiveCN105836752BReduce manufacturing costImprove performanceAlkaline-earth metal silicatesHigh concentrationThermal insulation

The invention provides a method for preparing xonotlite from calcium disodium silicate. The method comprises 1, mixing calcium disodium silicate and a sodium hydroxide solution, carrying out a reaction process at a temperature of 120-200 DEG C for 0.5-3h and orderly filtering and drying the reaction product to obtain a calcium silicate hydrate and 2, mixing the calcium silicate hydrate and water, carrying out gradient heating to a temperature of 200-260 DEG C, carrying out a thermal insulation reaction process for 1-8h and orderly filtering and drying the reaction products to obtain xonotlite. The method utilizes calcium disodium silicate-containing alkali-containing industrial residue as a raw material which has a low price and stable performances so that a xonotlite production cost is greatly reduced. The method can be operated by simple processes and has short reaction time. Alkali in calcium disodium silicate can be recovered and recycled in a form of a high concentration caustic solution so that the method is suitable for industrial production.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

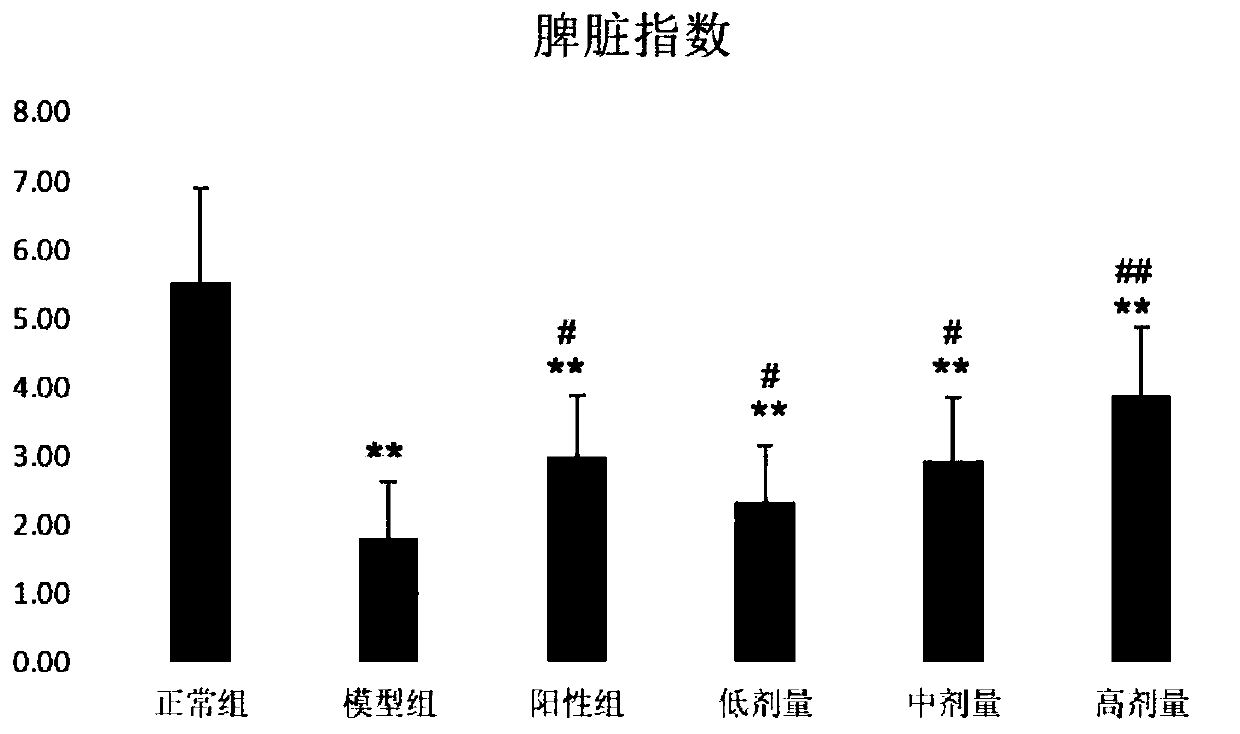

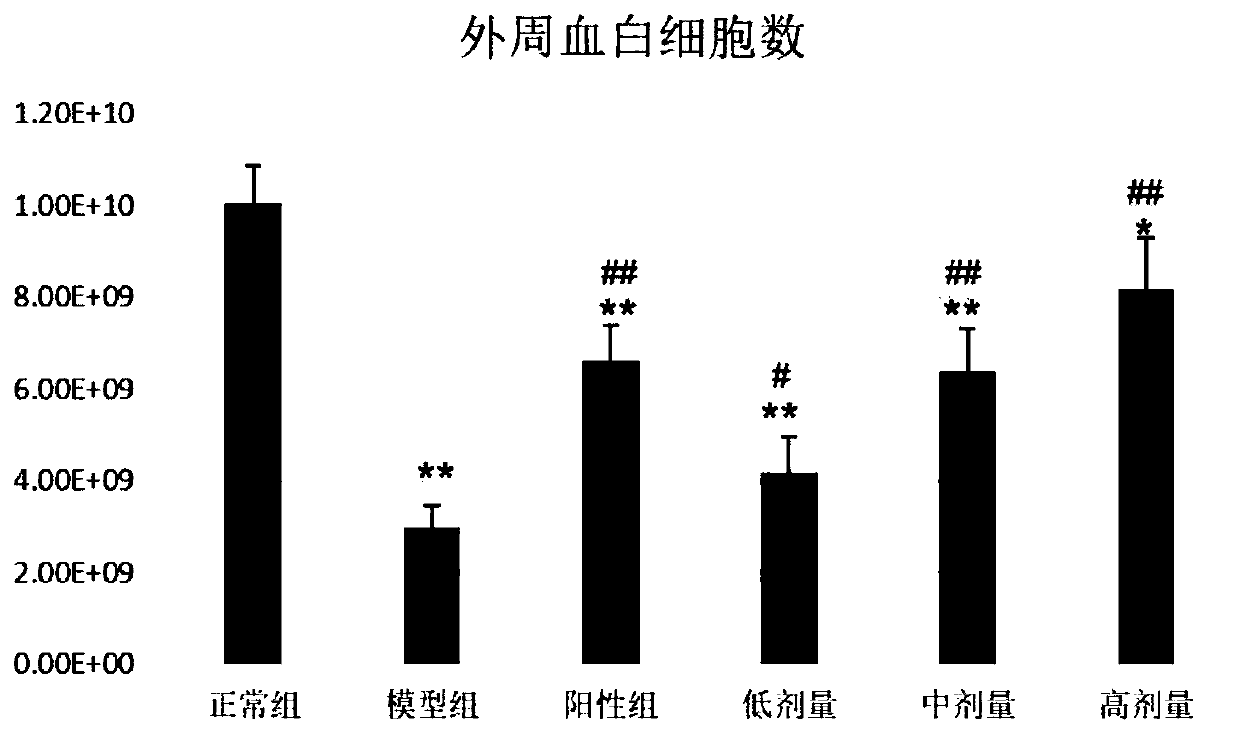

Pinctadafucata glycosaminoglycan containing effervescent tablet and preparation method thereof

InactiveCN109588604AEasy to removeShorten the enzymatic digestion timeFood ingredient functionsEffervescent tabletSide effect

The invention relates to a pinctadafucata glycosaminoglycan containing effervescent tablet and a preparation method thereof. The pinctadafucata glycosaminoglycan containing effervescent tablet comprises the following components in percent by weight: 15-25% of pinctadafucata glycosaminoglycan, 30-40% of a disintegrating agent, 1-3% of an adhesive agent, 1-3% of a lubricating agent, 2-4% of a flavoring agent and the balance of lactose. The pinctadafucata glycosaminoglycan containing effervescent tablet prepared by the preparation method provided by the invention is in the shape of a biplanarcircle, is clean and tidy in outer shape, smooth in surface and white and uniform in color and luster, is rapidly disintegrated and produces a large amount of gas in water, is soft in mouth feel and freeof impurities, has unique aroma and taste, is high in sensory quality and free of toxic and side effects, and helps to maintain the normal immune function of a body. By the preparation method, the technological operability is strong and the cost is low; the preparation method is suitable for industrial production; a technological innovation is provided for application of the pinctadafucata glycosaminoglycan and high-value development of shellfish meat; and the preparation method is of a great significance in promoting development of the pearl farming industry and the pearl processing industry.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

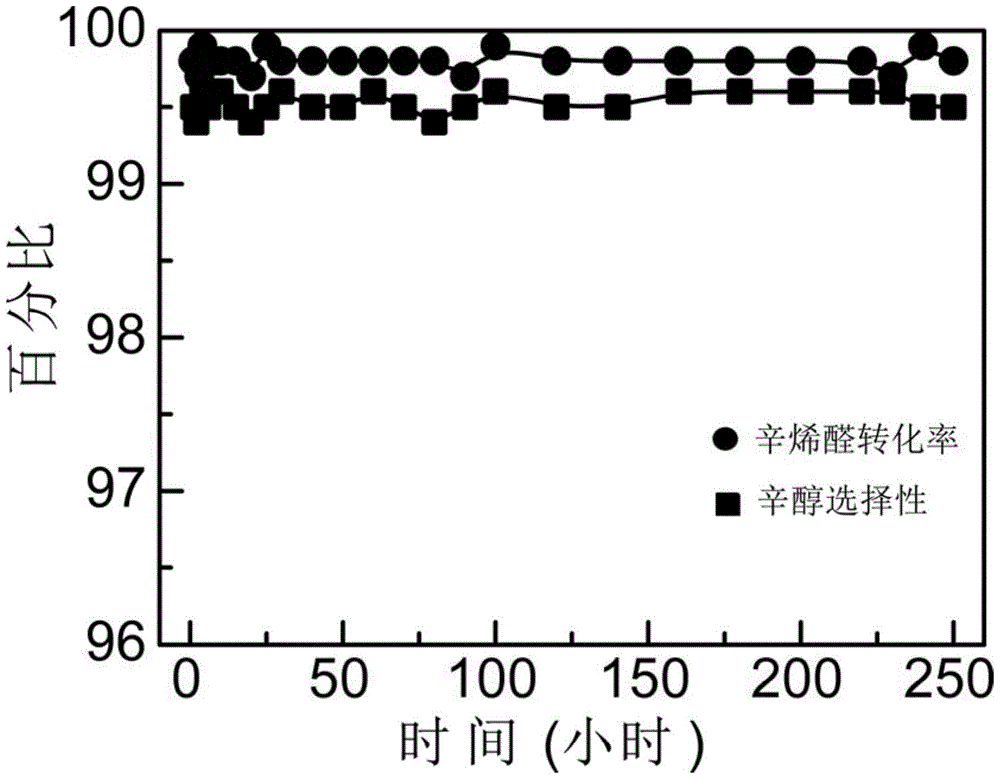

Catalyst for gas-phase hydrogenation of octenal to octanol and preparation method thereof

ActiveCN104549304BHigh selectivityImprove catalytic stabilityOrganic compound preparationPreparation by hydrogenationDispersityGas phase

The invention provides a catalyst for hydrogenating an octenal gas phase to prepare octanol and a preparation method of the catalyst. The method comprises the following steps: breaking and sieving a waste contact generated by producing methyl chlorosilane with a direct method; and carrying out steps of roasting, dissolving with acid, and hydrothermally settling with urea to modify so as to obtain the catalyst for hydrogenating the octenal gas phase to prepare octanol. The components include copper and zinc active components and a porous silicon oxide carrier. The catalyst has the advantages that the problem of high-value comprehensive utilization of the solid residue waste contact in an organic silicon synthesizing industry is solved; the cost of raw materials is low, the operation method is simple and the industrial production is easy to realize; and compared with an impregnation method and a co-precipitation method, the grain diameter of the catalyst prepared by a urea hydrothermal settling method is smaller and the dispersity is better, so that the catalyst has higher hydrogenating activity and higher octanol selectivity and catalyzing stability, the service life of the catalyst can be greatly prolonged and the repeatability is good.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

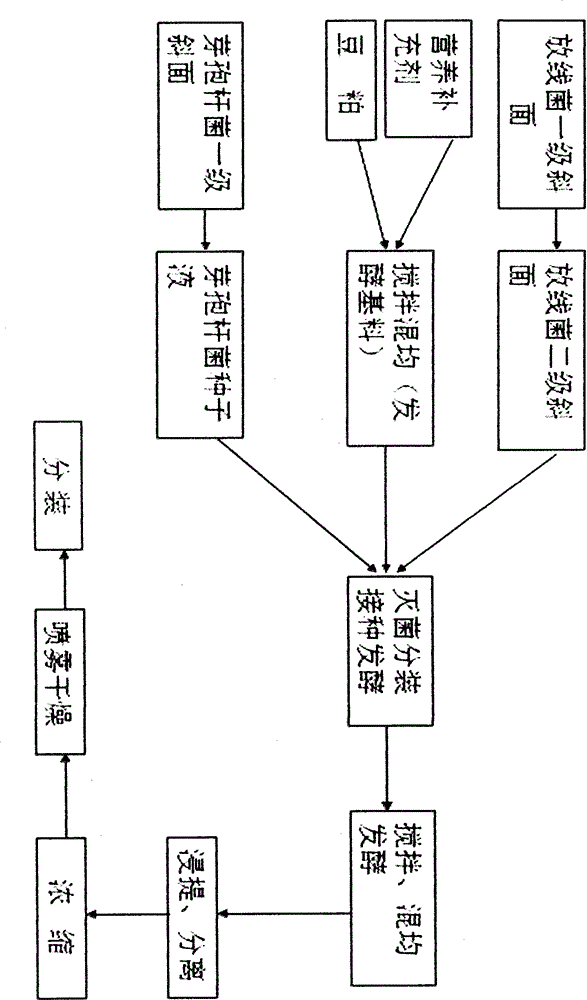

Method for comprehensively utilizing waste residues and liquid waste of animal biochemical products

InactiveCN102876763BHigh dissolution rateSimple processPeptide preparation methodsWater/sewage treatment bu osmosis/dialysisLiquid wasteMicrowave

The invention relates to a method for comprehensively utilizing waste residues and liquid waste of animal biochemical products and belongs to the technical field of biology. The method includes steps of enzymolysis of waste residues and liquid waste; bag filtration of enzymolysis liquid to obtain filter residues and filtrate; filtrate filtering by a micro-filtration membrane to obtain concentrated liquid and permeating liquid; nanofiltration and concentration of the permeating liquid and obtaining concentrated liquid and permeating liquid; secondary nanofiltration and concentration of the permeating liquid to obtain concentration liquid and permeating filtrate; dechlorinating and purifying of the permeating liquid by the reverse osmosis technology and respectively collecting the concentrated liquid and the permeating liquid; mixing the concentrated liquid with the residues of the bag filtration, microfiltration and combining the concentrated liquid of the primary nanofiltration; vacuum drying via microwaves and obtaining animal protein crude products for feeding and edible animal protein crude products; freezing and drying of the concentrated liquid of the secondary nanofiltration and obtaining officinal polypeptide crude products. The method for comprehensively utilizing waste residues and liquid waste of the animal biochemical products is simple in process and low in production cost, products at various levels are good in quality, comprehensive utilization level of the waste residues and the liquid waste of the animal biochemical products is improved, and the problems about environmental pollution and high-valued utilization are solved.

Owner:四川茂森生物科技有限公司

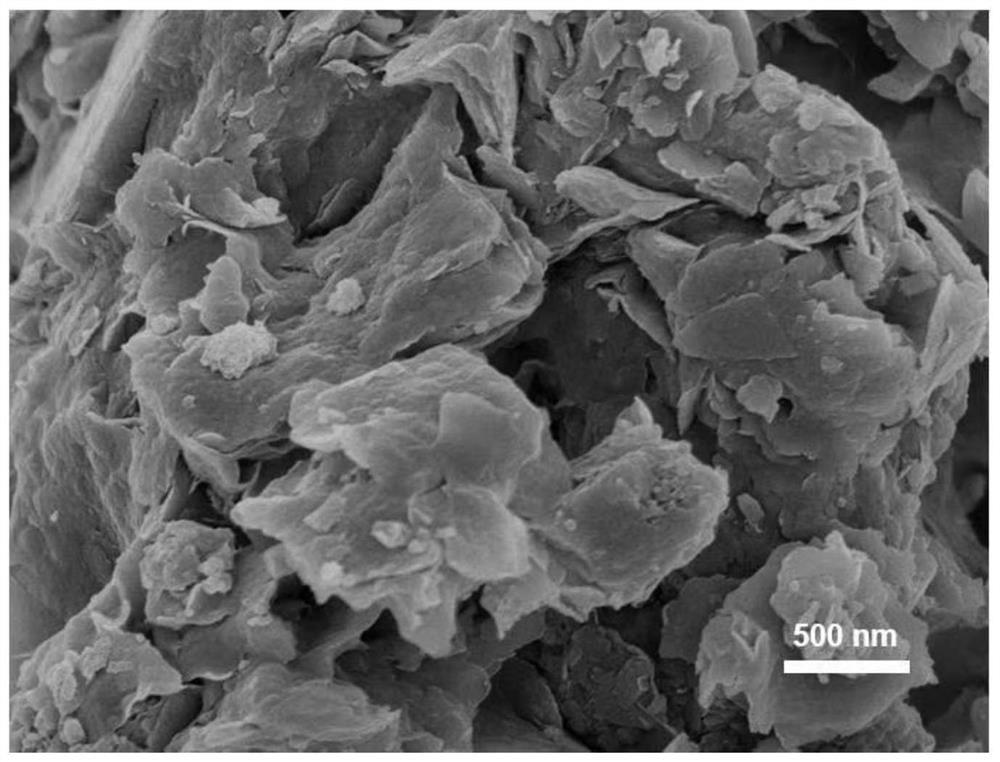

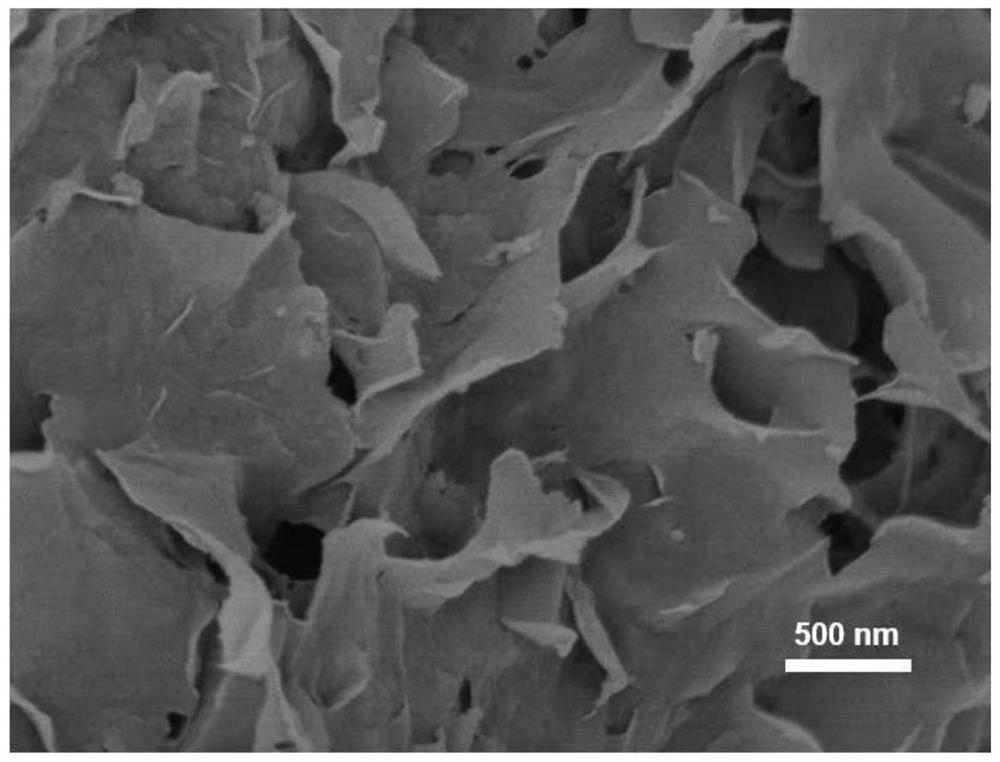

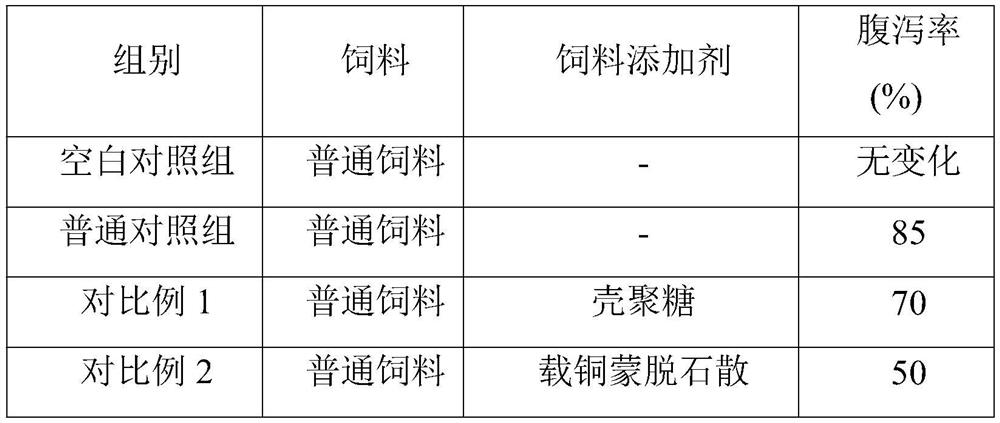

A kind of chitosan-copper-loaded montmorillonite intercalation composite material and its preparation method and application

ActiveCN112998147BProtectiveNo toxicityOrganic active ingredientsHeavy metal active ingredientsFeed additiveDiarrhea

The invention discloses a chitosan-copper-loaded montmorillonite intercalation composite material, a preparation method and an application thereof. Chitosan-copper-loaded montmorillonite intercalation composite material uses copper-loaded montmorillonite powder as the main material of the intercalation, and uses chitosan for intercalation composite, wherein the copper content of copper-loaded montmorillonite powder is 0.5% ~5%, the molecular weight of chitosan is 10~50kDa. The chitosan-copper-loaded montmorillonite powder intercalation composite material disclosed by the present invention has a large specific surface area. The copper-loaded montmorillonite powder is used as the main body of the intercalation composite material, and chitosan is used for intercalation fusion, which will have antibacterial properties. Combination of chitosan with astringent, mucosal repair and immune enhancement activities and copper-loaded montmorillonite powder with adsorption, antidiarrheal and antibacterial effects makes the two synergistic and can be better used for the treatment of porcine inflammatory bowel disease Prevention and control can reduce the diarrhea rate of weaned piglets and adult pigs to 20%, and can be widely used in the field of feed additives.

Owner:SHENZHEN INST OF GUANGDONG OCEAN UNIV

Device of separating and drying wet and dry kitchen waste rapidly

InactiveCN110887345AEasy to separate wet and drySolve health problemsDrying solid materials without heatSolid waste disposalEnvironmental engineeringFodder

The invention discloses a device of separating and drying wet and dry kitchen waste rapidly and belongs to the field of garbage cleaning devices. The device of separating and drying the wet and dry kitchen waste rapidly comprises a material extrusion mechanism arranged on a fixed support; the fixed support is fixedly provided with a hydraulic sealing mechanism; the material extrusion mechanism realizes separation and compression of wet and dry materials; and the hydraulic sealing mechanism controls discharge of the treated materials. According to the device of separating and drying the wet anddry kitchen waste rapidly, as a method of extruding forcibly by using a single screw, including the steps of firstly extruding liquid ingredients at a high pressure to remove water and then eliminating waste materials, is adopted, separation of wet and dry kitchen garbage can be carried out conveniently. The treated kitchen garbage powder is dry and the unpleasant odor thereof is reduced greatly;the dried kitchen garbage powder can be widely applied to feed processing and be returned to fields for fertilization; and the sanitation problem and the high-value utilization problem of the kitchengarbage are solved.

Owner:HUNAN UNIV OF TECH

A kind of method that utilizes disodium calcium silicate to prepare xonotlite

ActiveCN105819458BReduce manufacturing costImprove performanceAlkaline-earth metal silicatesXonotliteCalcium EDTA

The invention provides a method for preparing xonotlite from disodium silicate calcium. The method comprises the following steps that disodium silicate calcium and a sodium hydroxide solution are mixed, and the mixture is heated to reach the temperature of 200-260 DEG C through a temperature-gradient method and subjected to a heat-preserved reaction for 1-8 h; a reaction product is filtered and dried in sequence, and xonotlite is obtained. Alkali-containing industrial waste residue containing disodium silicate calcium is adopted as a raw material, the raw material is low in cost, easy to obtain and stable in performance, and therefore the production cost of the xonotlite is greatly reduced; in addition, the method is easy to operate, short in reaction time and particularly suitable for industrial production.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com