Catalyst for gas-phase hydrogenation of octenal to octanol and preparation method thereof

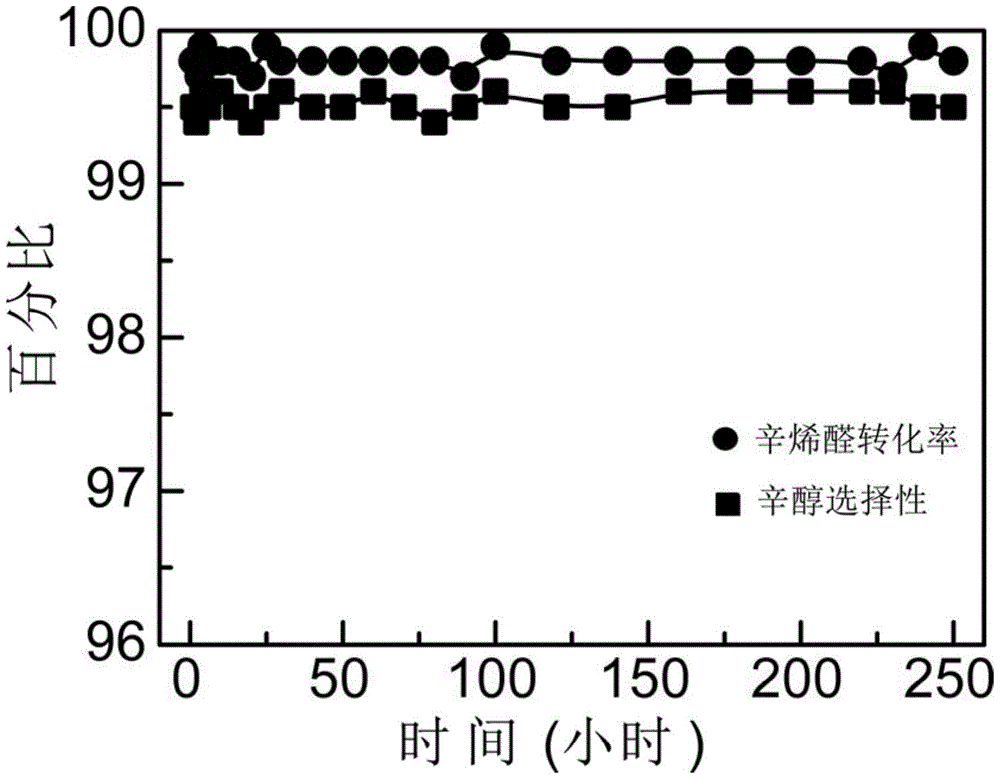

A catalyst, octenal technology, applied in hydrogenation preparation, chemical instruments and methods, hydroxyl compound preparation, etc., can solve the problems of poor dispersibility of octenal hydrogenation catalyst, cumbersome preparation process, environmental pollution, etc., and achieve high octanol. Selectivity and catalytic stability, simple operation method, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Take 10g of organic silicon waste contact body, whose particle size after crushing and sieving is 0.5-100μm; put it into a muffle furnace, roast at 450°C for 2h, and cool to room temperature; put it in a 1000mL beaker, add 0.5mol / L of nitric acid 200mL, react at 80°C for 2h under stirring; add 4gZn(NO 3 ) 2 ·6H 2 O, then add urea solution, adjust the pH value to 9, put it into a hydrothermal kettle, perform a hydrothermal reaction at 180° C. under autogenous pressure for 8 hours, wash and dry. Use nitrogen as carrier gas, control H 2 The content is 5%, and it is reduced at 160°C for 10h.

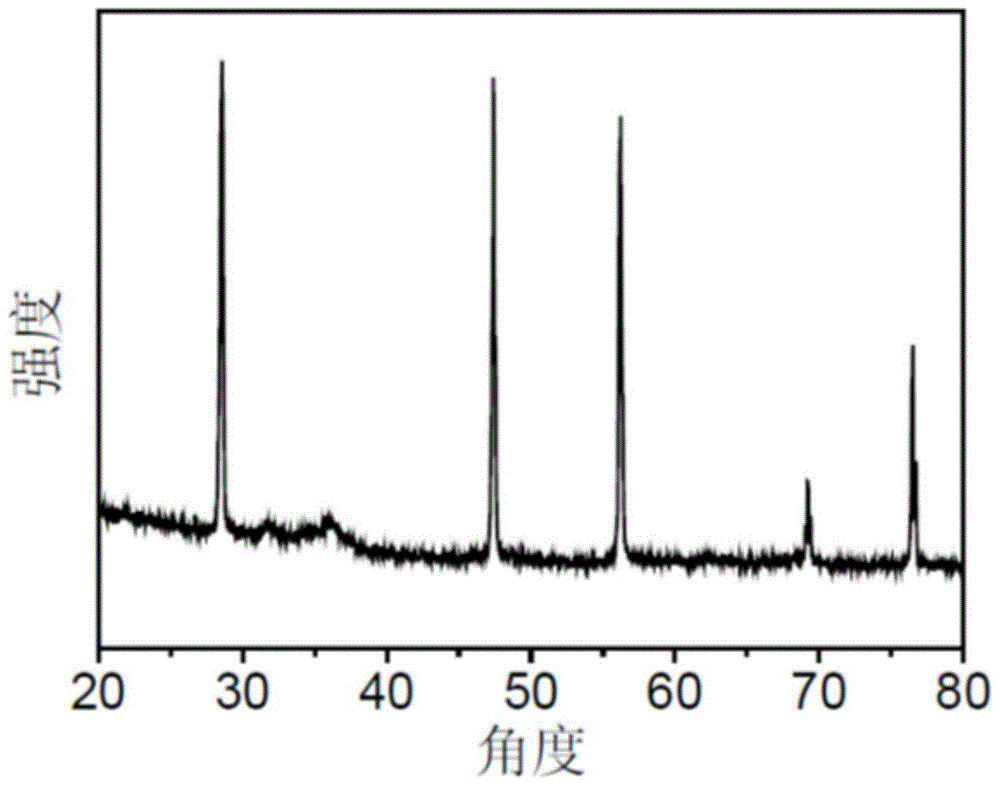

[0057] Carry out XRD test on the X 'Pert PRO MPD type multifunctional X-ray diffractometer of the X 'Pert PRO MPD type multifunctional X-ray diffractometer that the catalyst of above-mentioned preparation is produced in Holland Panalytical company (panalytical company); Carry out ICP test ( The same below).

[0058] figure 1 It is the XRD pattern of the unreduced catalyst in Ex...

Embodiment 2

[0060] Take 10g of organic silicon waste contact body, whose particle size after crushing and sieving is 0.5-100μm; put it into a muffle furnace, roast at 600°C for 4h, and cool to room temperature; put it in a 1000mL beaker, add 0.5mol / L sulfuric acid 200mL, reacted at 60°C for 6h under stirring; add 2gZn(NO 3 ) 2 ·6H 2 O, then add urea solution, adjust the pH to 12, put it into a hydrothermal kettle, perform a hydrothermal reaction at 140° C. under autogenous pressure for 12 hours, wash and dry. Use nitrogen as carrier gas, control H 2 The content is 7%, and it is reduced at 160°C for 10h.

[0061] ICP test results show that the copper element content is 8.3%, and the zinc element content is 3.2%.

Embodiment 3

[0063] Take 10g of organic silicon waste contact body, whose particle size after crushing and sieving is 0.5-100μm; put it into a muffle furnace, roast at 900°C for 8h, and cool to room temperature; put it in a 1000mL beaker, add 6mol / L of nitric acid 200mL, react at 40°C for 10h under stirring; add 10gZnSO 4 ·7H 2 O, then add urea solution, adjust the pH value to 14, put it into a hydrothermal kettle, perform a hydrothermal reaction at 120° C. under autogenous pressure for 16 hours, wash and dry. Use nitrogen as carrier gas, control H 2 The content is 8%, and it is reduced at 200°C for 4h.

[0064] ICP test results show that the copper element content is 23.8%, and the zinc element content is 9.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com