Catalyst for low-temperature synthesis of methanol and preparation method

A technology for synthesizing methanol and catalysts, which is applied in the preparation of organic compounds, chemical instruments and methods, and the preparation of hydroxyl compounds, etc. It can solve the problems of increasing the investment in the synthesis gas manufacturing process and the cost of synthesis gas, poor high temperature resistance, and low single-pass conversion rate. , achieving high methanol synthesis activity and thermal stability, easy large-scale production, and simple operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The "direct method" fluidized bed process commonly used in the silicone industry is used to prepare 5g of waste contacts produced in the process of preparing organosilicon monomer methylchlorosilane. 2 nanometers to 10 microns, wherein the silicon content is 84wt%, the copper content is 6wt%, and the carbon content is 10wt%. .

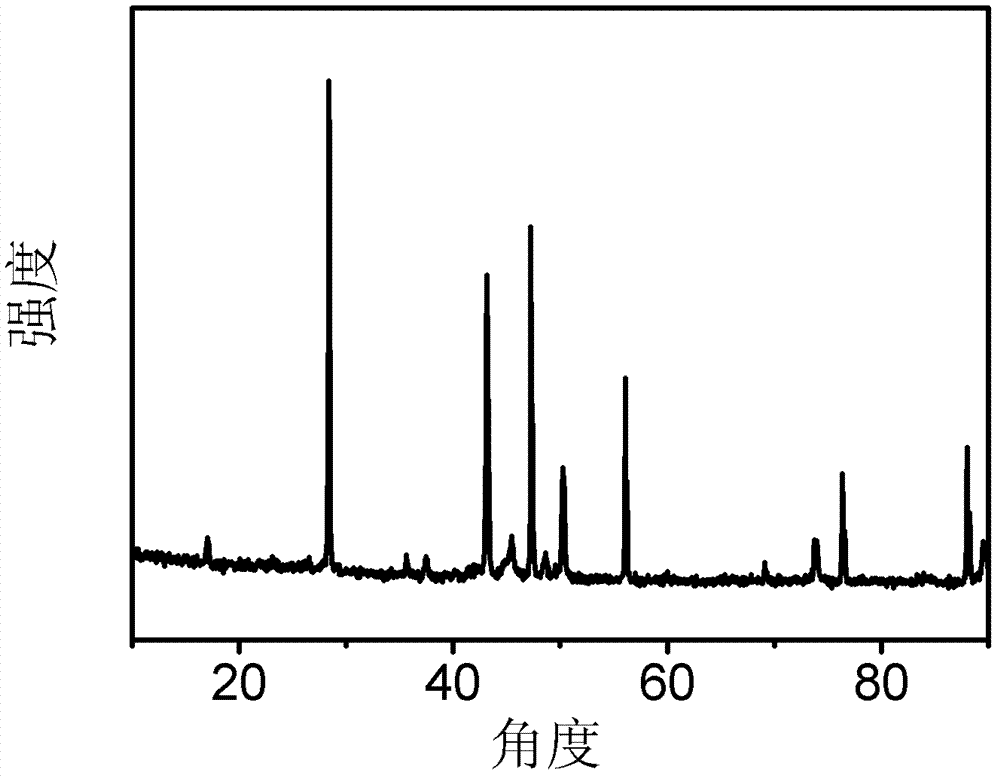

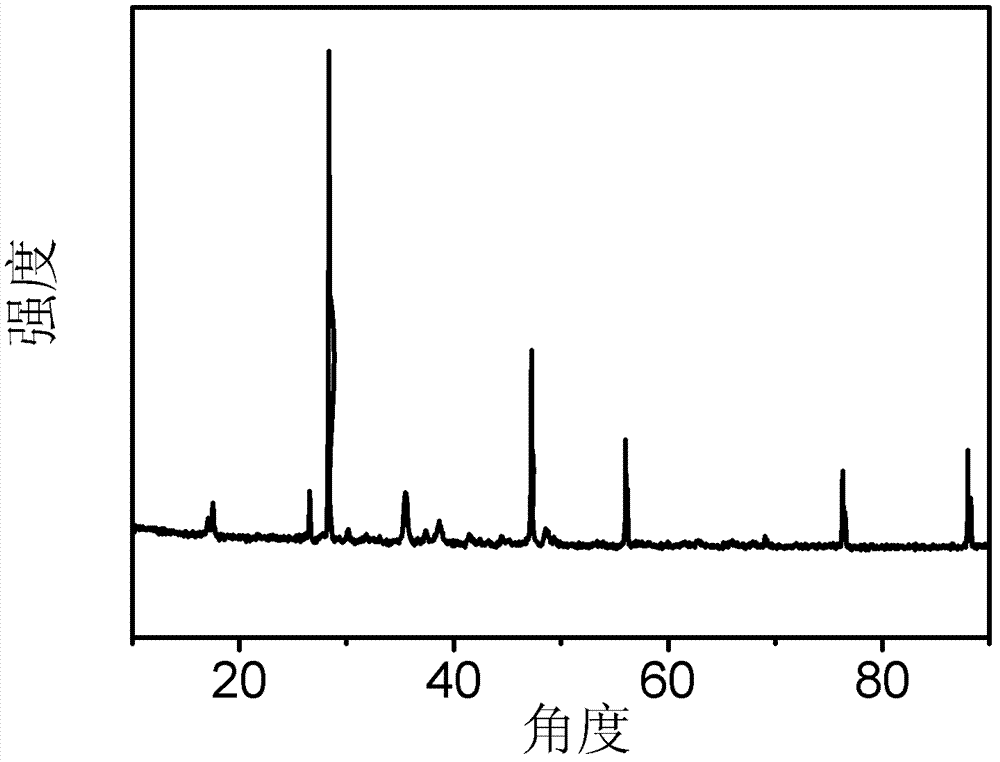

[0046] The catalyst material prepared above was subjected to XRD test on the X'Pert PROMPD multifunctional X-ray diffractometer produced by Panalytical Company (Panalytical) in the Netherlands.

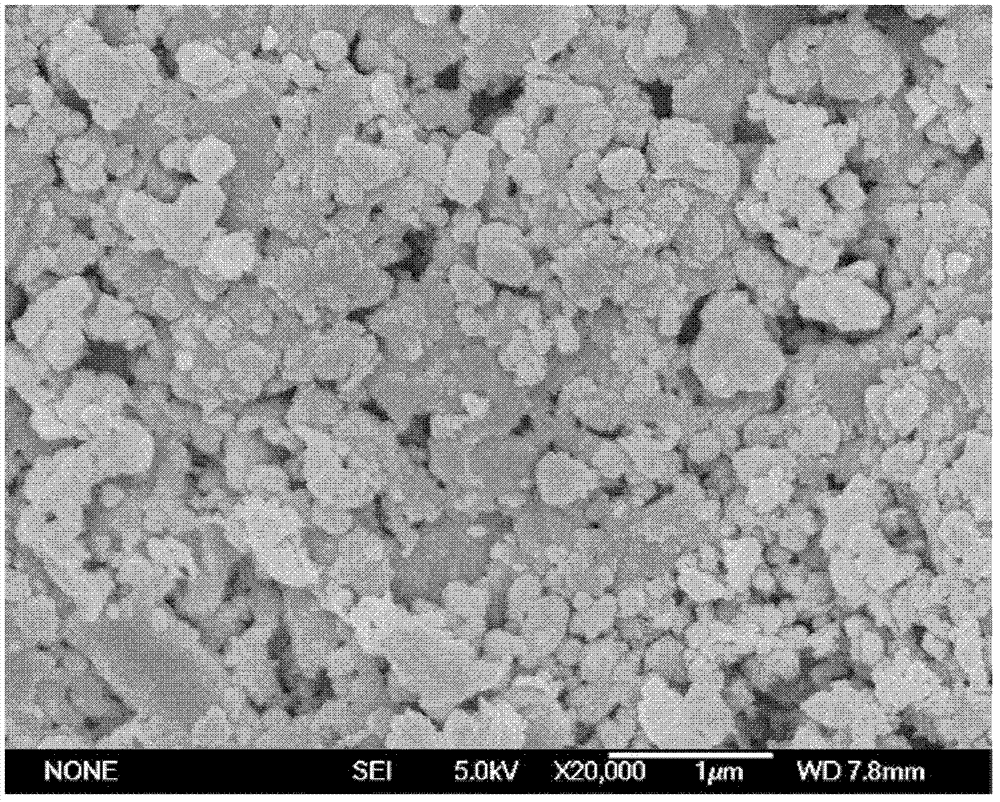

[0047] The surface morphology of the catalyst material prepared above was observed with a JSM6700 field emission scanning electron microscope produced by JEOL Ltd.

[0048] The catalyst material prepared above was subjected to a TG test on a model TG / DTA6300 enthusiasm analyzer produced by Japan SEICO.

[0049] The catalyst materials prepared above were tested by ICP on the Pekin-Elmer Inductively Coupled Plasma Atomic Emission Spectrometer in the Uni...

Embodiment 2

[0054] The "direct method" fluidized bed process commonly used in the silicone industry is used to prepare 5g of waste contacts produced in the process of preparing organosilicon monomer methylchlorosilane. 2 nanometers to 10 microns, where the silicon content is 84wt%, the copper content is 6wt%, and the carbon content is 10wt%. After washing twice with 100mL of benzene and chloroform, filter and dry in a vacuum oven at 100°C for 2 hours. , placed in a muffle furnace, heated at 100°C for 10h, and cooled to room temperature. The catalyst materials prepared above were tested by ICP on the Pekin-Elmer Inductively Coupled Plasma Atomic Emission Spectrometer in the United States, and the results are shown in Table 1.

[0055] figure 2 For the XRD pattern of the catalyst obtained in Example 2, wherein 2θ=28.6° is the characteristic peak of Si, the shoulder peak composed of 2θ=35.5° and 2θ=38.7° is the characteristic peak of CuO, and 2θ=26.6° is the characteristic peak of C Peak,...

Embodiment 3

[0059] The "direct method" fluidized bed process commonly used in the silicone industry is used to prepare 5g of waste contacts produced in the process of preparing organosilicon monomer methylchlorosilane. 2 nanometers to 10 microns, where the silicon content is 84wt%, the copper content is 6wt%, and the carbon content is 10wt%. After washing twice with 100mL of toluene and acetone, filter and dry in a vacuum oven at 100°C for 2 hours. , placed in a muffle furnace, heated at 900°C for 0.5h, then passed through an inert gas, heated at 800°C for 10h, and cooled to room temperature to obtain a silicon / copper oxide porous composite catalyst for synthesis gas to methanol. The catalyst materials prepared above were tested by ICP on the Pekin-Elmer Inductively Coupled Plasma Atomic Emission Spectrometer in the United States, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com