Method for comprehensively utilizing waste residues and liquid waste of animal biochemical products

A technology of animal biochemical products, waste residue and waste liquid, which is applied in the direction of osmosis/dialysis water/sewage treatment, fermentation, etc., can solve the problems of high solid content in spray drying, not meeting the requirements of water recycling, and low utilization rate, etc. Environmental pollution and high-value utilization issues, the realization of comprehensive utilization of deep processing and economy, and the effect of improving the level of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

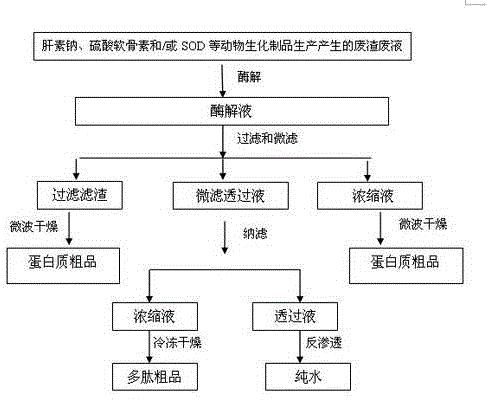

Image

Examples

Embodiment 1

[0031] The comprehensive utilization method of waste residue and waste liquid in the production of heparin sodium, chondroitin sulfate and SOD animal biochemical products: includes the following process steps:

[0032] Step 1: Use trypsin to catalyze the hydrolysis of waste residues and liquids generated during the production of animal biochemical products to obtain an enzymolysis solution; trypsin is added in an amount of 0.10% by weight, enzymolysis time is 5 hours, and the temperature is 50°C.

[0033] Step 2: Filter the enzymatic hydrolysis solution in the first step with a 100-mesh bag filter, and collect the filter residue and filtrate respectively; among them, the filter residue is a crude protein product with a protein content of 5% or more; the filtrate is subjected to subsequent microfiltration processing deal with.

[0034] The third step: the filtrate collected in the second step is concentrated by microfiltration with a 0.05 μm microfiltration membrane, and the co...

Embodiment 2

[0041] The comprehensive utilization method of waste residue and waste liquid in the production of heparin sodium, chondroitin sulfate and SOD animal biochemical products: includes the following process steps:

[0042] Step 1: Use trypsin to catalyze the hydrolysis of waste residues and liquids generated during the production of animal biochemical products to obtain an enzymolysis solution; trypsin is added in an amount of 0.15% by weight, enzymolysis time is 3 hours, and the temperature is 30°C.

[0043]Step 2: Filter the enzymolysis solution in the first step with an 80-mesh bag filter, and collect the filter residue and filtrate respectively; among them, the filter residue is a protein crude product above 80 mesh, and its protein content is 6%; the filtrate is subjected to subsequent microfiltration processing deal with.

[0044] The third step: the filtrate collected in the second step is concentrated by microfiltration using a 0.8 μm microfiltration membrane, and the conc...

Embodiment 3

[0051] The comprehensive utilization method of waste residue and waste liquid in the production of heparin sodium, chondroitin sulfate and SOD animal biochemical products: includes the following process steps:

[0052] Step 1: Use trypsin to catalyze the hydrolysis of waste residues and liquids in the production of animal biochemical products to obtain an enzymolysis solution; trypsin is added in an amount of 0.04% by weight, enzymolysis time is 6 hours, and the temperature is 70°C.

[0053] Step 2: Filter the enzymolysis solution in the first step with a 200-mesh bag filter, and collect the filter residue and filtrate respectively; among them, the filter residue is a crude protein product with a protein content of 3% or more; the filtrate is subjected to subsequent microfiltration processing deal with.

[0054] The third step: the filtrate collected in the second step is concentrated by microfiltration with a 0.1 μm microfiltration membrane, and the concentrate and permeate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com