Device of separating and drying wet and dry kitchen waste rapidly

A technology of kitchen waste and drying equipment, which is applied in the direction of drying garbage, drying solid materials, and drying solid materials without heating. It can solve the problems of polluting the environment, high moisture content and easy breeding of bacteria, etc., and achieve dry texture and solve hygiene problems. Problems related to high-value utilization and the effect of odor reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

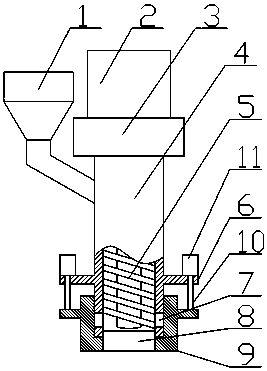

[0018] Such as figure 1 As shown, a quick separation and drying device for dry and wet kitchen waste includes a lower hopper 1, a drive motor 2, a reduction box 3, a cylinder body 4, a screw 5, a fixed support 6, a discharge port 7, a filter screen 8, and a sealing mold Head 9, clamping rod 10, hydraulic cylinder 11. Bottom hopper 1, driving motor 2, reduction box 3, cylinder body 4 and screw 5 form a material extrusion system, and sealing die 9, clamping rod 10, and hydraulic cylinder 11 form a hydraulic sealing mechanism.

[0019] Several outlets 7 are arranged at the front end of the cylinder body 4, two fixed supports 6 are arranged symmetrically on the sides of the cylinder body 4, and a filter screen 8 is arranged at the front end of the cylinder body 4, which is connected with the front end of the cylinder body 4 through threads, and the filter screen 8 The mesh number is about 120-170 mesh, which only allows liquids such as moisture and oil to pass through.

[0020] ...

Embodiment 2

[0022] This embodiment discloses the working principle of the dry and wet kitchen waste rapid separation and drying device. First, the dry and wet mixed kitchen waste is put into the lower hopper 1, and the kitchen waste enters the screw 5 under the action of its own weight, and the sealing die head 9 is locked. Tight, discharge port 7 is sealed.

[0023] The kitchen waste is conveyed forward under the rotation of the screw 5 and is compressed in the thread and the gap between the screw 5 and the filter screen 8 at the same time, and the water in the solid waste material is squeezed out and discharged through the filter screen 8 .

[0024] When the torque of the drive motor 2 reaches the set value, the hydraulic cylinder 11 drives the sealed die head 9 to open the mold through the clamping rod 19, opens the discharge port 7, and the compressed and squeezed material continues to be extruded from the discharge port 7, and the process is completed. Dry and wet separation of garba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com