A system for producing activated carbon from straw

A technology for producing activated carbon and straw, applied in inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of increasing the cost of activated carbon, high equipment corrosion, polluting the environment, etc., to achieve unique equipment, fast construction, increase yield and quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

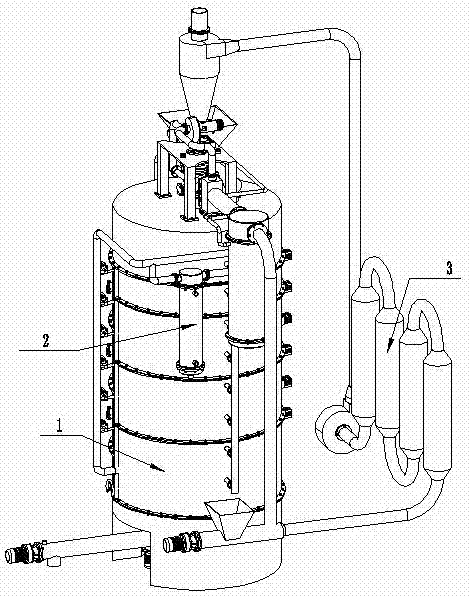

[0024] A system for producing activated carbon by using straw, including a fried activated carbon furnace 1, a straw feeding system 3 and a flue gas air activator delivery system 2,

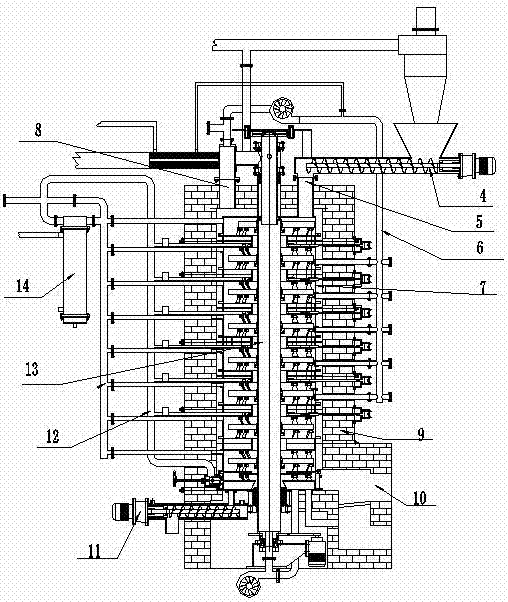

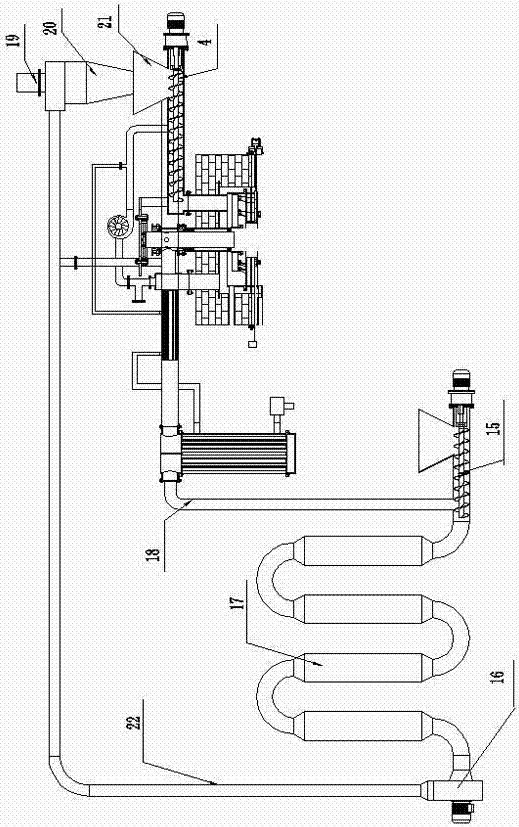

[0025] The fried activated carbon furnace is provided with a body of furnace, the body of furnace is provided with an insulating shell 9, and a hearth 7 is arranged in the insulating shell, and the upper part of the body of furnace is provided with a feed pipe 5 and a smoke exhaust pipe 8, and a smoke exhaust pipe 8 Connected with the flue gas main pipe 26, the upper port of the feed pipe 5 is provided with a screw feeder 4, the lower part of the furnace body is provided with an activated carbon discharge port, and the furnace body from the feed port to the discharge port is provided with a vertical The hearth is arranged vertically, and there is a hearth composed of several fixed furnace sections vertically stacked together in the hearth. The center of the hearth is provided with a rotating mandr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com