Method for producing amino acid fertilizer from soybean meal through solid-state fermentation

A solid-state fermentation and amino acid technology, applied in the direction of nitrogen fertilizer, to achieve the effect of improving the soil environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

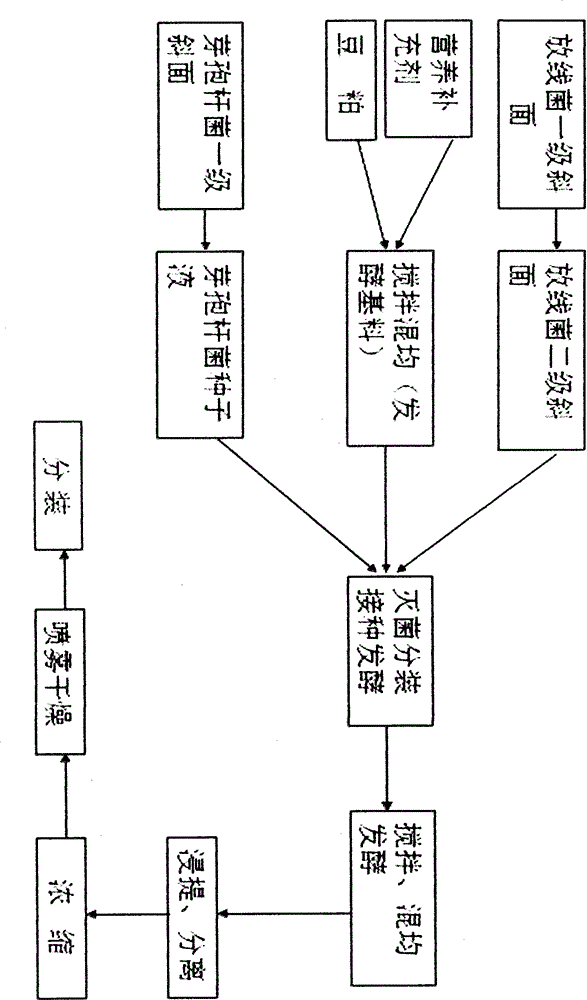

Image

Examples

Embodiment 1

[0014] 1000g of soybean meal was used as solid fermentation base; 10g of glucose, 2g of beef extract, KH 2 PO 4 1g, NaCl 1g, MgSO 4 1g, FeSO 4 Mix 0.1g with water to make 1000g nutritional supplement, and adjust the pH value to 7.0 with 1M NaOH aqueous solution; mix the above-mentioned soybean meal solid fermentation base material into the nutritional supplement, and mix the two evenly according to the weight ratio of 1:1 to make a solid fermented Put the culture medium into a polyethylene plastic bag, tie the mouth of the bag tightly, cook at 100°C for 8 minutes, and cool down.

[0015] When inoculating, first prepare actinomycetes seeds: use Gao’s No. 1 medium for the first-level slant, and cultivate it at 32°C for 4 days, and inoculate the second-level slant. . Then prepare Bacillus seed liquid: use nutrient agar for the primary slant, culture at 32°C for 36 hours, inoculate the secondary nutrient broth liquid medium, shake and culture at 32°C for 36 hours to logarithm...

Embodiment 2

[0020] Mix 900g of soybean meal with 100g of bran as a solid fermentation base material; in addition, 10g of glucose, 2g of beef extract, KH 2 PO 4 1g, NaCl 1g, MgSO 4 1g, FeSO 4 Mix 0.1g with water to make 1000g nutritional supplement, adjust the pH value to 7.0 with 1M NaOH aqueous solution; mix the above solid fermentation base material into the nutritional supplement, and mix the two evenly according to the weight ratio of 1:1.5 to make a solid fermentation culture Base, put it into a polyethylene plastic bag, tie the mouth of the bag tightly, cook at 100°C for 8 minutes, and cool.

[0021] When inoculating, first prepare actinomycetes seeds: use Gao’s No. 1 medium for the first-level slant, and cultivate it at 32°C for 4 days, and inoculate the second-level slant. . Then prepare Bacillus seed solution: use nutrient agar for the primary slant, culture it at 32°C for 36 hours, inoculate the secondary nutrient broth liquid medium, and shake it on a shaker at 32°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com