Method for comprehensively utilizing waste residues and liquid waste of animal biochemical products

A technology of animal biochemical products, waste residues and waste liquids, applied in the biological field, can solve the problems of high spray-dried solid content, low utilization rate, and failure to meet the requirements of water recycling, and achieve environmental pollution and high-value utilization. Improving the level of comprehensive utilization and good quality of products at all levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

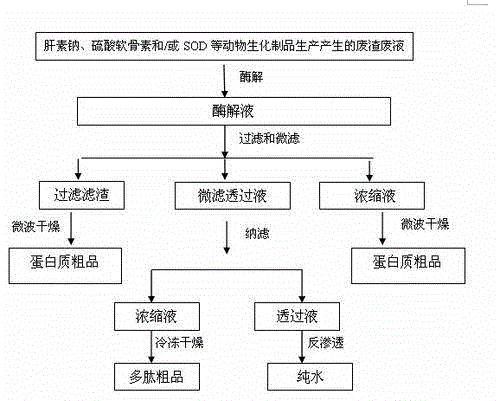

Image

Examples

Embodiment 1

[0032] The comprehensive utilization method of waste residue and waste liquid in the production of heparin sodium, chondroitin sulfate and SOD animal biochemical products: includes the following process steps:

[0033] Step 1: Use trypsin to catalyze the hydrolysis of waste residues and liquids generated during the production of animal biochemical products to obtain an enzymolysis solution; trypsin is added in an amount of 0.10% by weight, enzymolysis time is 5 hours, and the temperature is 50°C.

[0034] Step 2: Filter the enzymatic hydrolysis solution in the first step with a 100-mesh bag filter, and collect the filter residue and filtrate respectively; among them, the filter residue is a crude protein product with a protein content of 5% or more; the filtrate is subjected to subsequent microfiltration processing deal with.

[0035] The third step: the filtrate collected in the second step is concentrated by microfiltration with a 0.05 μm microfiltration membrane, and the co...

Embodiment 2

[0042] The comprehensive utilization method of waste residue and waste liquid in the production of heparin sodium, chondroitin sulfate and SOD animal biochemical products: includes the following process steps:

[0043] Step 1: Use trypsin to catalyze the hydrolysis of waste residues and liquids generated during the production of animal biochemical products to obtain an enzymolysis solution; trypsin is added in an amount of 0.15% by weight, enzymolysis time is 3 hours, and the temperature is 30°C.

[0044]Step 2: Filter the enzymolysis solution in the first step with an 80-mesh bag filter, and collect the filter residue and filtrate respectively; among them, the filter residue is a protein crude product above 80 mesh, and its protein content is 6%; the filtrate is subjected to subsequent microfiltration processing deal with.

[0045] The third step: the filtrate collected in the second step is concentrated by microfiltration with a 0.8 μm microfiltration membrane, and the conce...

Embodiment 3

[0052] The comprehensive utilization method of waste residue and waste liquid in the production of heparin sodium, chondroitin sulfate and SOD animal biochemical products: includes the following process steps:

[0053] Step 1: Use trypsin to catalyze the hydrolysis of waste residues and liquids in the production of animal biochemical products to obtain an enzymolysis solution; trypsin is added in an amount of 0.04% by weight, enzymolysis time is 6 hours, and the temperature is 70°C.

[0054] Step 2: Filter the enzymolysis solution in the first step with a 200-mesh bag filter, and collect the filter residue and filtrate respectively; among them, the filter residue is a crude protein product with a protein content of 3% or more; the filtrate is subjected to subsequent microfiltration processing deal with.

[0055] The third step: the filtrate collected in the second step is concentrated by microfiltration with a 0.1 μm microfiltration membrane, and the concentrate and permeate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com