A kind of method that utilizes disodium calcium silicate to prepare xonotlite

A technology of disodium calcium silicate and xonotlite, which is applied in the direction of silicate, alkaline earth metal silicate, etc., can solve the problems of long production time, high production cost, long time, etc., achieve stable performance and reduce production Cost, effect of improving physical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

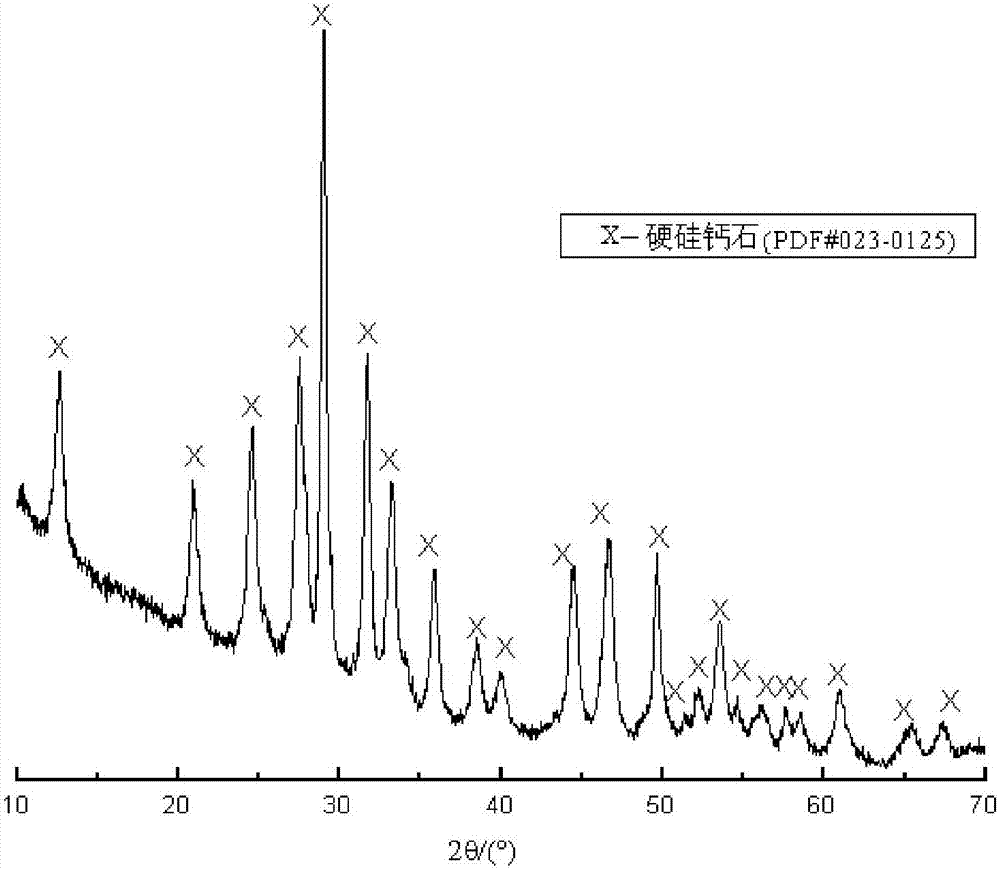

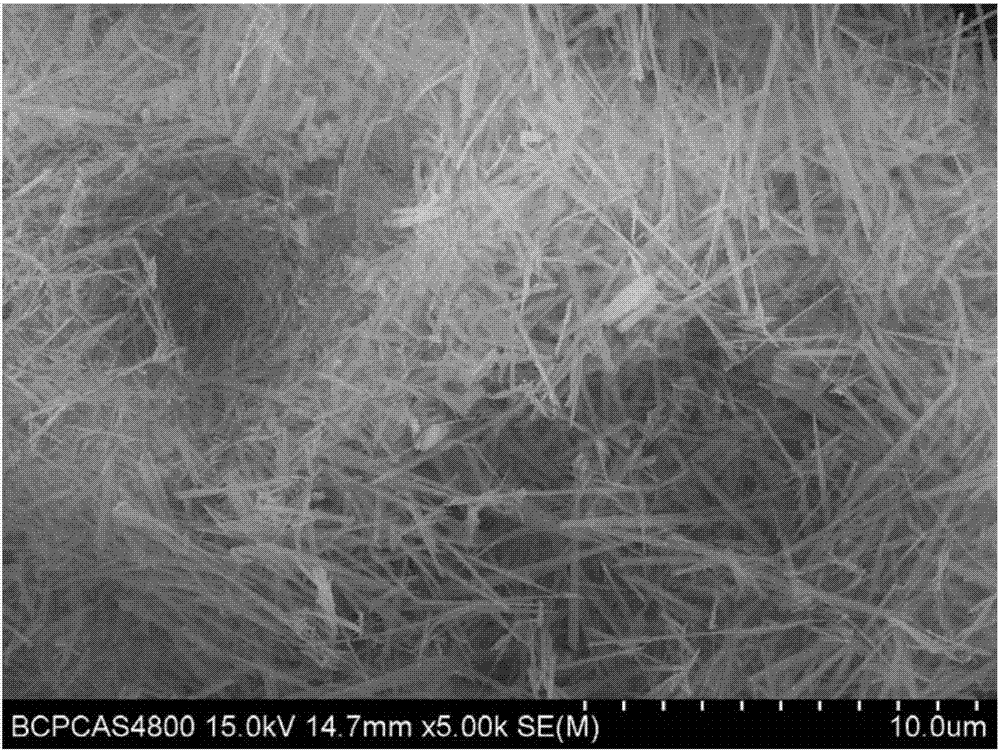

Image

Examples

Embodiment 1

[0026] The raw material disodium calcium silicate used in this example comes from the dissolution of NaAlO from soda lime sintered clinker 2 The chemical composition of the remaining residue is shown in Table 1.

[0027] The chemical composition of table 1 disodium calcium silicate raw material (content unit: wt %)

[0028] Element

Na 2 o

CaO

SiO 2

al 2 o 3

K 2 o

MgO

Fe 2 o 3

LOI

content

23.16

29.86

31.58

2.54

0.92

0.86

0.79

9.57

[0029] 1. Preparation of hydrated calcium silicate

[0030] Take caustic soda with a purity of 99wt%, fully dissolve it in 400g of distilled water, and prepare about 400mL of sodium hydroxide solution with a concentration of about 50g / L for subsequent use.

[0031] Weigh about 100.0g of the above disodium calcium silicate, add it to the 400mL sodium hydroxide solution prepared above, stir evenly, place it in an experimental high-pressure reactor with an effe...

Embodiment 2

[0042] The raw material disodium calcium silicate used in this example comes from the dissolution of NaAlO from soda lime sintered clinker 2 The chemical composition of the remaining waste residue is shown in Table 3.

[0043] The chemical composition of table 3 disodium calcium silicate raw material (content unit: wt%)

[0044] Element

Na 2 o

CaO

SiO 2

al 2 o 3

K 2 o

MgO

Fe 2 o 3

LOI

content

22.37

29.45

30.86

2.04

0.84

0.89

0.82

11.87

[0045] 1. Preparation of hydrated calcium silicate

[0046] Take caustic soda with a purity of 99wt%, fully dissolve it in 500g of distilled water, and prepare about 500mL of sodium hydroxide solution with a concentration of about 80g / L for subsequent use.

[0047] Weigh about 100.0 g of the above disodium calcium silicate, add it to the 500 mL sodium hydroxide solution prepared above, stir evenly, place it in an experimental high-pressure reactor with...

Embodiment 3

[0057] The raw material disodium calcium silicate used in this example comes from the dissolution of NaAlO from soda lime sintered clinker 2 The chemical composition of the remaining waste residue is shown in Table 5.

[0058] The chemical composition of table 5 disodium calcium silicate raw material (content unit: wt%)

[0059] Element

Na 2 o

CaO

SiO 2

al 2 o 3

K 2 o

MgO

Fe 2 o 3

LOI

content

21.09

29.00

29.32

2.78

0.67

0.71

0.93

14.87

[0060] 1. Preparation of hydrated calcium silicate

[0061] Take caustic soda with a purity of 99wt%, fully dissolve it in 600g of distilled water, and prepare about 600mL of sodium hydroxide solution with a concentration of about 60g / L for subsequent use.

[0062] Weigh about 200.0g of the above disodium calcium silicate, add it to the 600mL sodium hydroxide solution prepared above, stir evenly, place it in an experimental high-pressure reactor with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com