Composite plasticizer taking chlorinated glycerol ester as main body as well as preparation method and application thereof

A technology of chloroglycerol ester and compound plasticizer, applied in the field of polymer materials, can solve the problem that the high value-added processing of crude glycerin cannot be completely solved, the diglyceride cannot be used as a plasticizer, and the refining of crude glycerol cannot be eliminated. Steps and other problems, to solve the high-value utilization of direct high conversion rate, increase the chlor-alkali industry chain, and avoid the effect of being unable to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

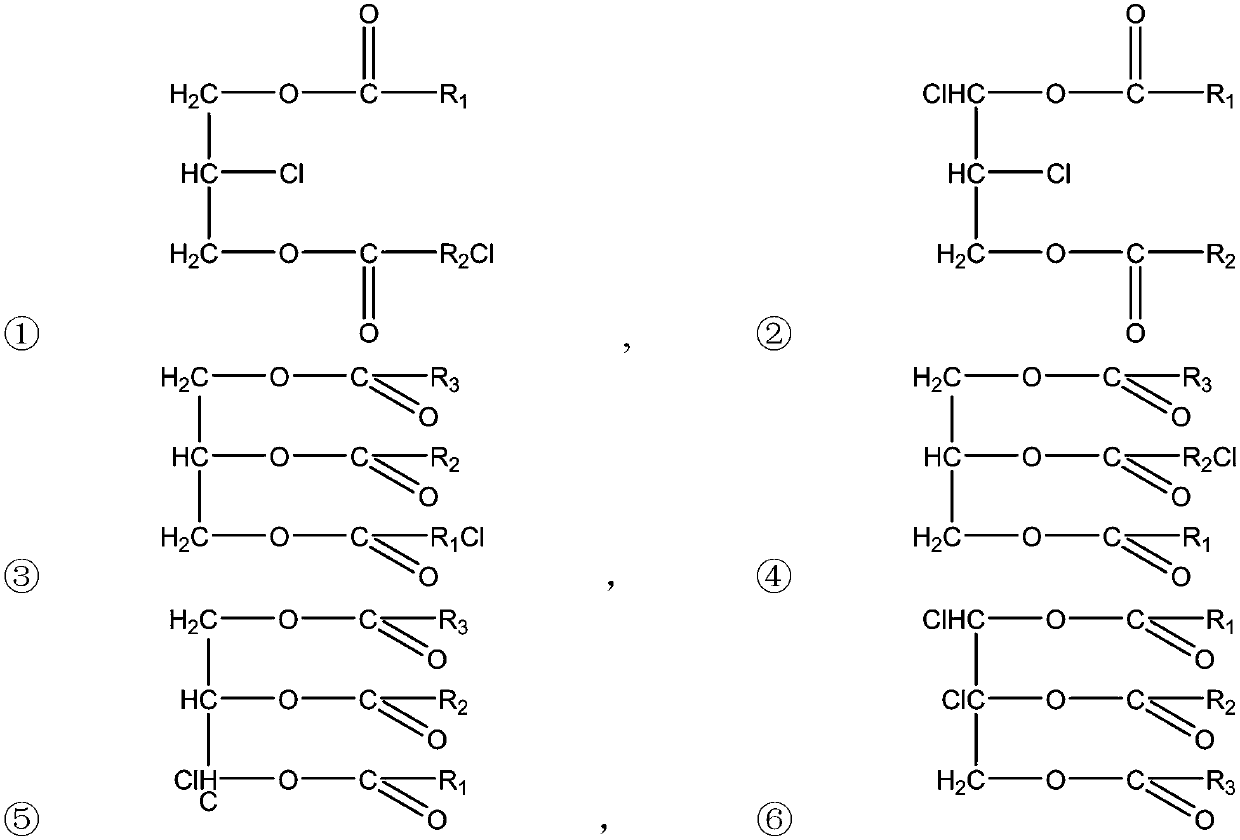

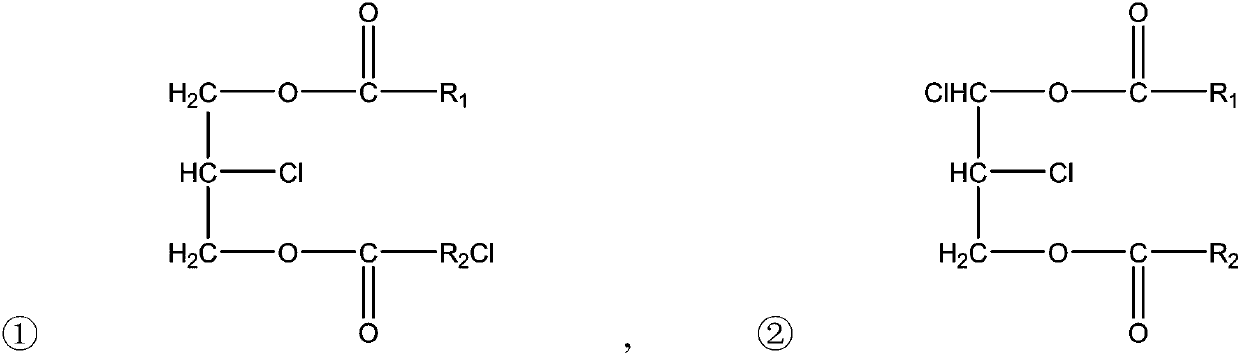

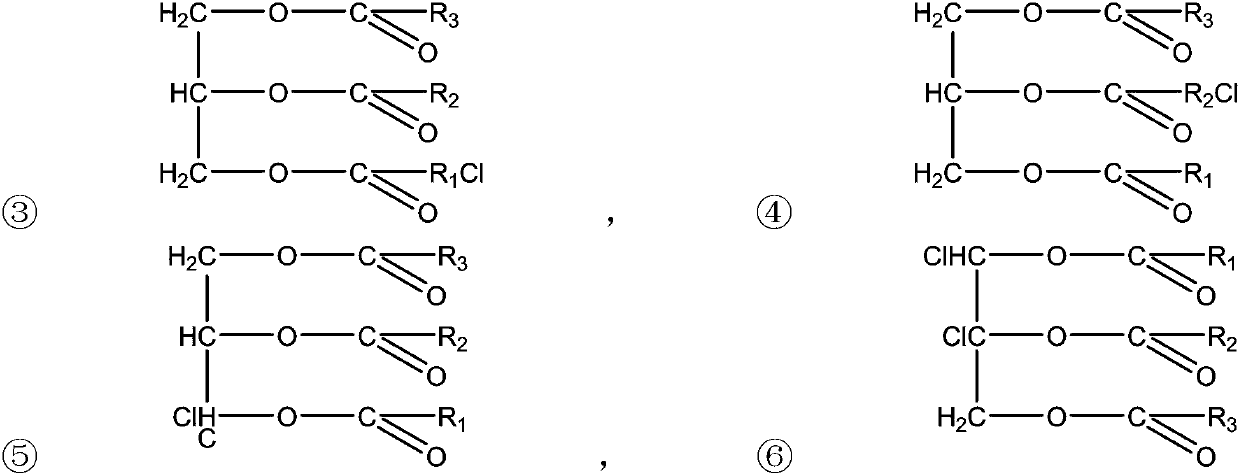

Image

Examples

preparation example Construction

[0030] In one embodiment of the present invention, the preparation method of the composite plasticizer taking chloroglycerol ester as main body, comprises the following steps:

[0031] A) Put crude glycerin, alkyl acid or benzoic acid, water-carrying agent and esterification catalyst in a reactor, and react at 80-140°C for 2-5 hours to obtain a dark red liquid;

[0032] B) Distilling the dark red liquid under reduced pressure, collecting fractions below 1kPa and above 100°C to obtain an intermediate product;

[0033] C) after mixing the intermediate product with the chlorination catalyst, carry out chlorination reaction with chlorine gas under light to obtain the composite plasticizer initial product;

[0034] D) Adding 3% by weight stabilizer, 0.5% by weight of surfactant and 5%-10% by weight of viscosity reducer to the initial composite plasticizer product to obtain a composite plasticizer product.

[0035] In one embodiment of the present invention, the crude glycerol is a...

Embodiment 1

[0050] Get the crude glycerin 115g of biodiesel by-product (proportioning is: glycerol 81%, water 10%, inorganic salt 3%, other impurity and colored matter 3%), glacial acetic acid 240g, lanthanum chloride 2.2g and acetic acid Put 72g of ethyl ester in a three-necked flask, raise the temperature to 105°C while stirring constantly, and some components will start to evaporate, and the generated water will be separated continuously through the water separator until 3-4 hours later, no more water will be generated, stop reaction;

[0051] Use a mechanical pump for vacuum distillation, collect fractions below 1kPa and above 100°C, and the fractions are colorless liquids with a faint ester aroma;

[0052] Add a mixture of benzoyl peroxide and tert-butyl peroxybenzoate with a mass fraction of 1‰ to this fraction, and under the irradiation of ultraviolet light, when the water bath is maintained at 60-70°C, chlorine gas is introduced to carry out the chlorination reaction, and the reac...

Embodiment 2

[0056] Get crude glycerol 115g (proportioning by weight percentage is: glycerol 82%, water 6%, inorganic salt 4%, other impurity and colored matter 4%), formic acid 184g, tin chloride 4.6g, dichloroethane 80g, constantly While stirring, the temperature is raised to 85°C, and the components begin to evaporate, and the generated water is continuously separated through the water separator until 2-3 hours later, no more water is generated, and the reaction is stopped.

[0057] Use a mechanical pump to carry out vacuum distillation, collect the fraction below 1kPa and above 100°C, the fraction is a colorless liquid with a faint ester aroma.

[0058] Add a mixture of azobisisobutyronitrile and tert-butyl peroxybenzoate with a mass fraction of 1‰ to the fraction, and under the irradiation of an ultraviolet lamp, when the water bath is maintained at 60-70°C, chlorine gas is introduced to carry out the chlorination reaction, After reacting for 1.5 hours, stop feeding the chlorine gas a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com