Preparation method of silicon carbide

A silicon carbide and roasting technology, applied in silicon carbide, carbide and other directions, can solve the problems of complex silicon carbide synthesis process, high preparation process requirements, unfavorable large-scale production, etc., to solve the problem of high-value utilization and simplify the preparation process. Process, the effect of shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a method for preparing silicon carbide, the preparation method comprising the following steps:

[0055] (1) Sieve tire semi-coke to obtain 45-53 μm powder as carbon source, 180-280 μm quartz sand as silicon source, and mix the two at a mass ratio of 8:9.

[0056] (2) Place the alumina crucible containing the mixture in a reaction furnace for the first heat treatment under a helium atmosphere, heat it to 1050°C, the heating rate is 10°C / min, and the holding time is 60min; then proceed to the second heat treatment Heat treatment, heating to 1520°C for reaction, the heating rate is 5°C / min, the holding time is 420min, and then cooled to room temperature.

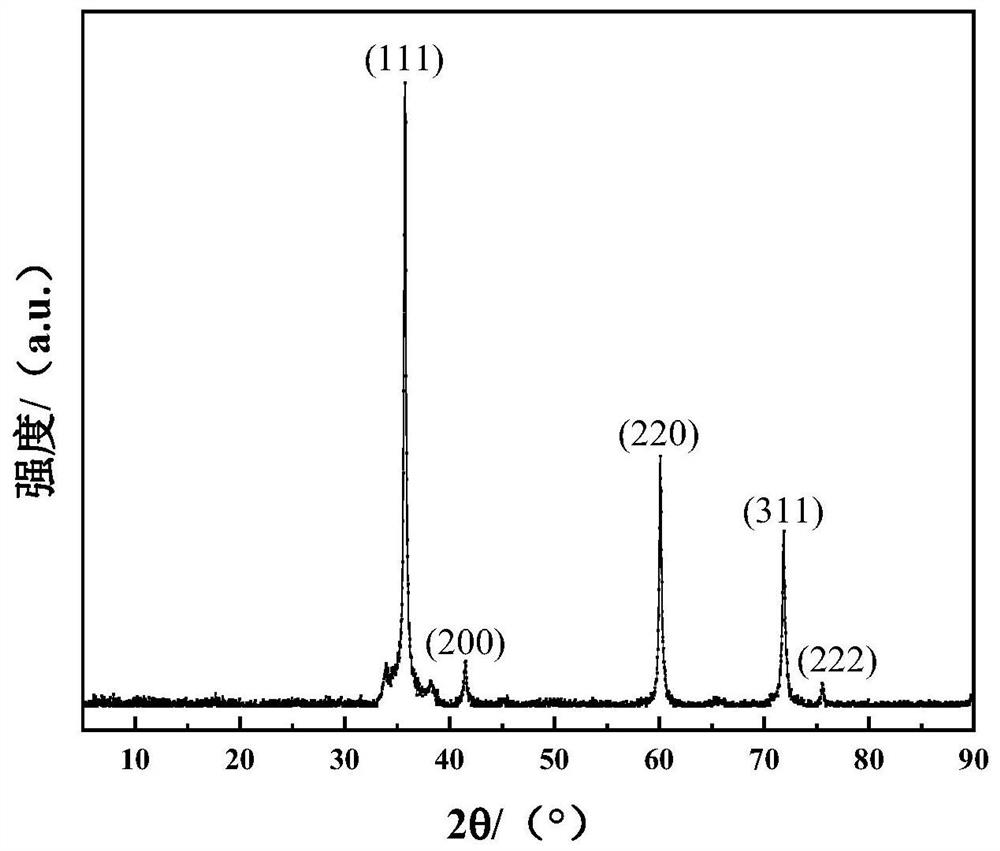

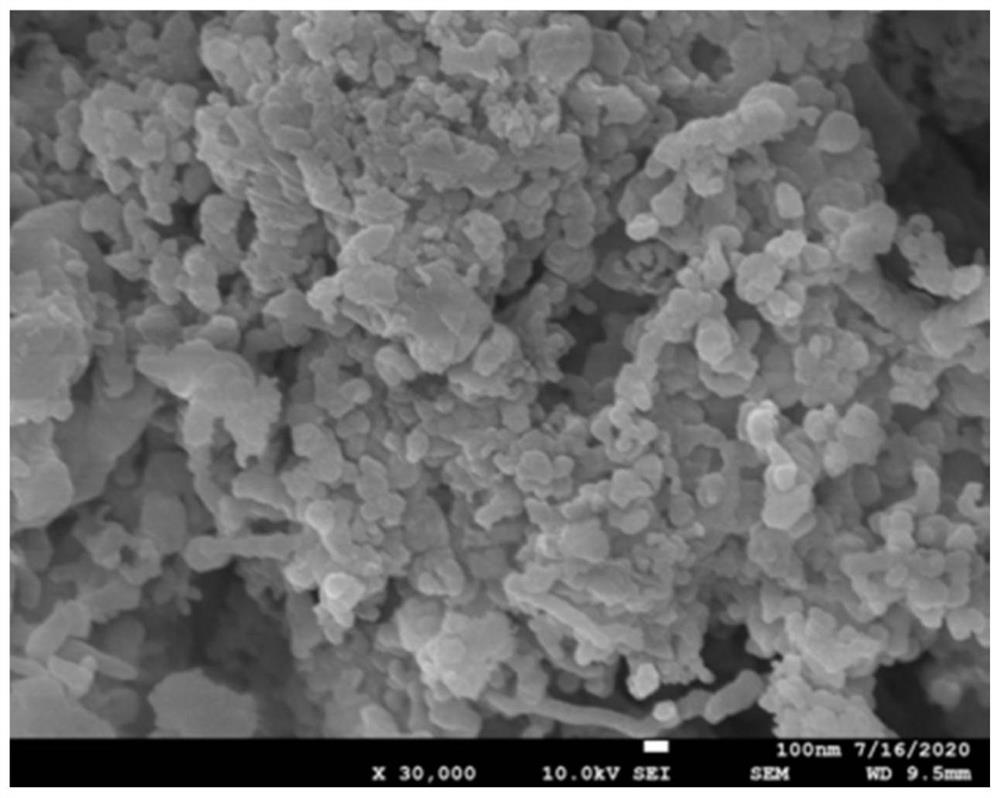

[0057] (3) Move the product obtained after the reaction in step (2) to a roasting furnace, and heat up to 700°C for 180 minutes at a heating rate of 15°C / min in an air atmosphere to obtain silicon carbide. See Table 1 for detailed parameters. The obtained silicon carbide The XRD pattern of figu...

Embodiment 2

[0059] This embodiment provides a method for preparing silicon carbide, the preparation method comprising the following steps:

[0060] (1) Sieve tire semi-coke to obtain 710-850 μm powder as carbon source, 45-53 μm quartz sand as silicon source, mix the two at a mass ratio of 1.5:1, add water for wet mixing, wet mixing The mass ratio of powder and water is 2.5:1.

[0061] (2) Place the alumina crucible containing the mixture in a reaction furnace for the first heat treatment under an argon atmosphere, heat it to 900°C, the heating rate is 10°C / min, and the holding time is 60min; then proceed to the second heat treatment Heat treatment, heating to 1800°C for reaction, the heating rate is 5°C / min, the holding time is 240min, and then cooled to room temperature.

[0062] (3) Move the product obtained after the reaction in step (2) to a roasting furnace, and heat up to 300 °C for 360 min at a heating rate of 20 °C / min in an air atmosphere to obtain silicon carbide. See Table 1 f...

Embodiment 3

[0064] This embodiment provides a method for preparing silicon carbide, the preparation method comprising the following steps:

[0065] (1) Sieve tire semi-coke to obtain 40-50mm powder as carbon source, 10-15mm quartz sand as silicon source, mix the two at a mass ratio of 5:1, add ethanol for wet mixing, wet mixing The mass ratio of powder and ethanol is 4.5:1.

[0066] (2) Place the alumina crucible containing the mixture in a reaction furnace for the first heat treatment under an argon atmosphere, heat it to 1200°C, the heating rate is 5°C / min, and the holding time is 200min; and then proceed to the second heat treatment Heat treatment, heating to 2400°C for reaction, the heating rate is 10°C / min, the holding time is 500min, and then cooled to room temperature.

[0067] (3) Move the product obtained after the reaction in step (2) to a roasting furnace, and heat it up to 500 °C for 120 min in an air atmosphere at a heating rate of 5 °C / min to obtain silicon carbide. See Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com