Continuous reproduction technology using biomass wastes and waste liquid

A biomass and waste technology, applied in the direction of chemicals for biological control, biofuels, applications, etc., can solve the problem that the biomass pyrolysis and carbonization process cannot be continuously produced, and the high-value utilization of biomass waste and waste liquid cannot be achieved and other problems, to achieve the effect of solving high-value utilization problems, excellent environmental protection performance, and strong antibacterial and bactericidal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by way of examples, but it is not intended to limit the present invention. Unless otherwise specified, methods such as alkali washing, separation, discharge, distillation and refining involved in the present invention are all conventional methods in the art.

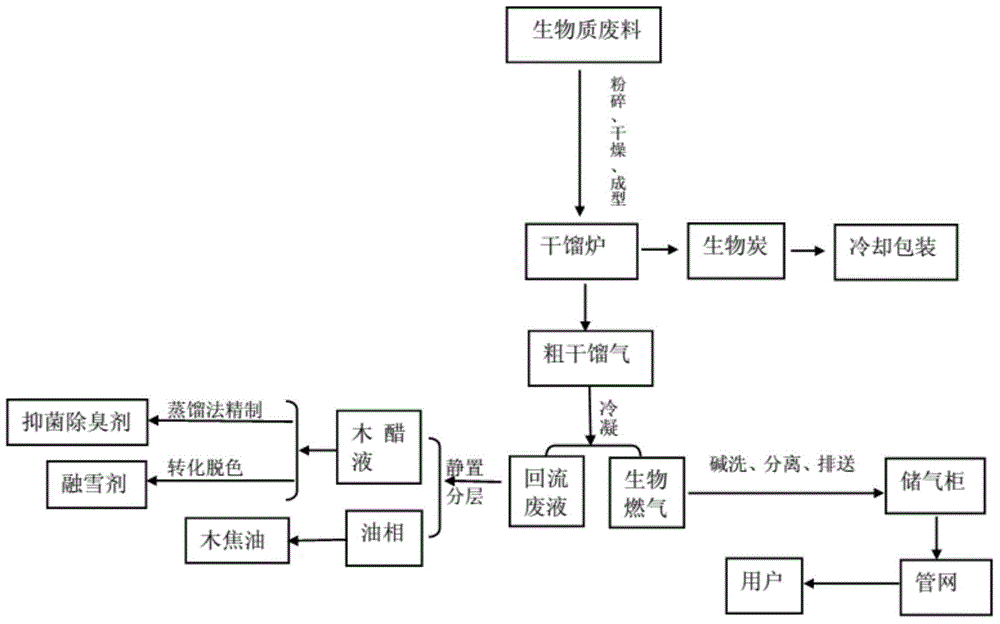

[0015] Biomass waste can be selected from forest tending branches, wood processing residues, sawdust, bagasse, cellulose, straw, absorbent cotton or fruit shells. In this embodiment, forest tending branches and wood processing residues such as wood shavings are selected as biomass raw materials. After , drying, and forming, weigh 1 ton of material and send it to a carbonization furnace for carbonization. Control the temperature of the furnace at 400-600 ° C. After 4 hours of reaction, biochar and crude carbonization gas are obtained, and 330 kg of biochar is cooled and packaged as a finished product. After the crude retort gas is condensed, the gas ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com