A kind of preparation method of soil conditioner using phosphogypsum as raw material

A soil conditioner and phosphogypsum technology, which is applied in soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve the problems that soil conditioners are difficult to widely use, and achieve the effects of resource utilization, enhanced capacity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

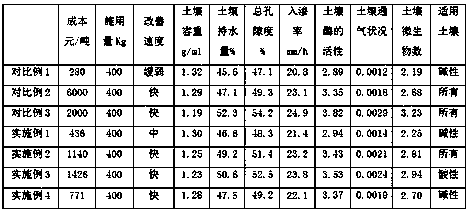

Image

Examples

Embodiment 1

[0034] (1) Grinding the phosphogypsum waste residue produced by the phosphorus chemical industry to 20 meshes to obtain phosphogypsum powder;

[0035] (2) The weight ratio of phosphogypsum powder (on dry basis) to wet-process activated carbon (on dry basis) is 1:0.1, and the phosphogypsum powder obtained in step (1) is uniformly mixed with wet-process activated carbon to obtain a mixture;

[0036] Wherein, the wet-process activated carbon is made according to the following method:

[0037] a. Crushing the straw to 200 mesh to obtain straw powder;

[0038] b. According to step a, the weight ratio of straw powder to industrial waste sulfuric acid is 1:40, the straw powder obtained in step a is mixed with industrial waste sulfuric acid with a concentration of 90wt%, and reacted at 160°C at a rotation speed of 20rpm for 6 hours, get the reactants;

[0039] c, separating the reactant obtained in step b to obtain a solid product and a filtrate, repeatedly washing the solid product...

Embodiment 2

[0044] (1) Grinding the phosphogypsum waste residue produced by the phosphorus chemical industry to 60 meshes to obtain phosphogypsum powder;

[0045] (2) The weight ratio of phosphogypsum powder (on dry basis) to wet-process activated carbon (on dry basis) is 1:1, and the phosphogypsum powder obtained in step (1) is uniformly mixed with wet-process activated carbon to obtain a mixture;

[0046] Wherein, the wet-process activated carbon is made according to the following method:

[0047] a. Dissolve 400 mesh glucose with 1 times water;

[0048] b. According to step a, the weight ratio of glucose and titanium dioxide waste acid with a concentration of 93wt% is 1:2, mix the glucose obtained in step a with titanium dioxide waste acid, and oscillate at 100°C at an oscillation frequency of 60 times / min React for 10 seconds to get the reactant;

[0049] c, separating the reactant obtained in step b to obtain a solid product and a filtrate, repeatedly washing the solid product with...

Embodiment 3

[0054] (1) Grinding the phosphogypsum waste residue produced by the phosphorus chemical industry to 120 mesh to obtain phosphogypsum powder;

[0055] (2) According to the weight ratio of phosphogypsum powder (on dry basis) to wet-process activated carbon (on dry basis) is 1:2, the phosphogypsum powder obtained in step (1) and wet-process activated carbon are uniformly mixed to obtain a mixture;

[0056] Wherein, the wet-process activated carbon is made according to the following method:

[0057] a. Dissolve 200g of 120-mesh tapioca starch with 4 times of water, and heat to 80°C for gelatinization while stirring;

[0058] B, according to the weight ratio of the tapioca starch after step a gelatinization and the alkylation waste sulfuric acid that concentration is more than 60wt% is 1:12, under the agitation condition of 1 revolution / second, step a gained tapioca starch and alkylation The waste sulfuric acid was mixed, and then placed in an ultrasonic instrument at 80°C for 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com