Agitator Ball Mill and Method for Operating an Agitator Ball Mill

A technology of agitating ball milling and milling, which is applied in chemical instruments and methods, solid separation, and separation of solids from solids with airflow, etc. It can solve problems such as increased wear and blocked product discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

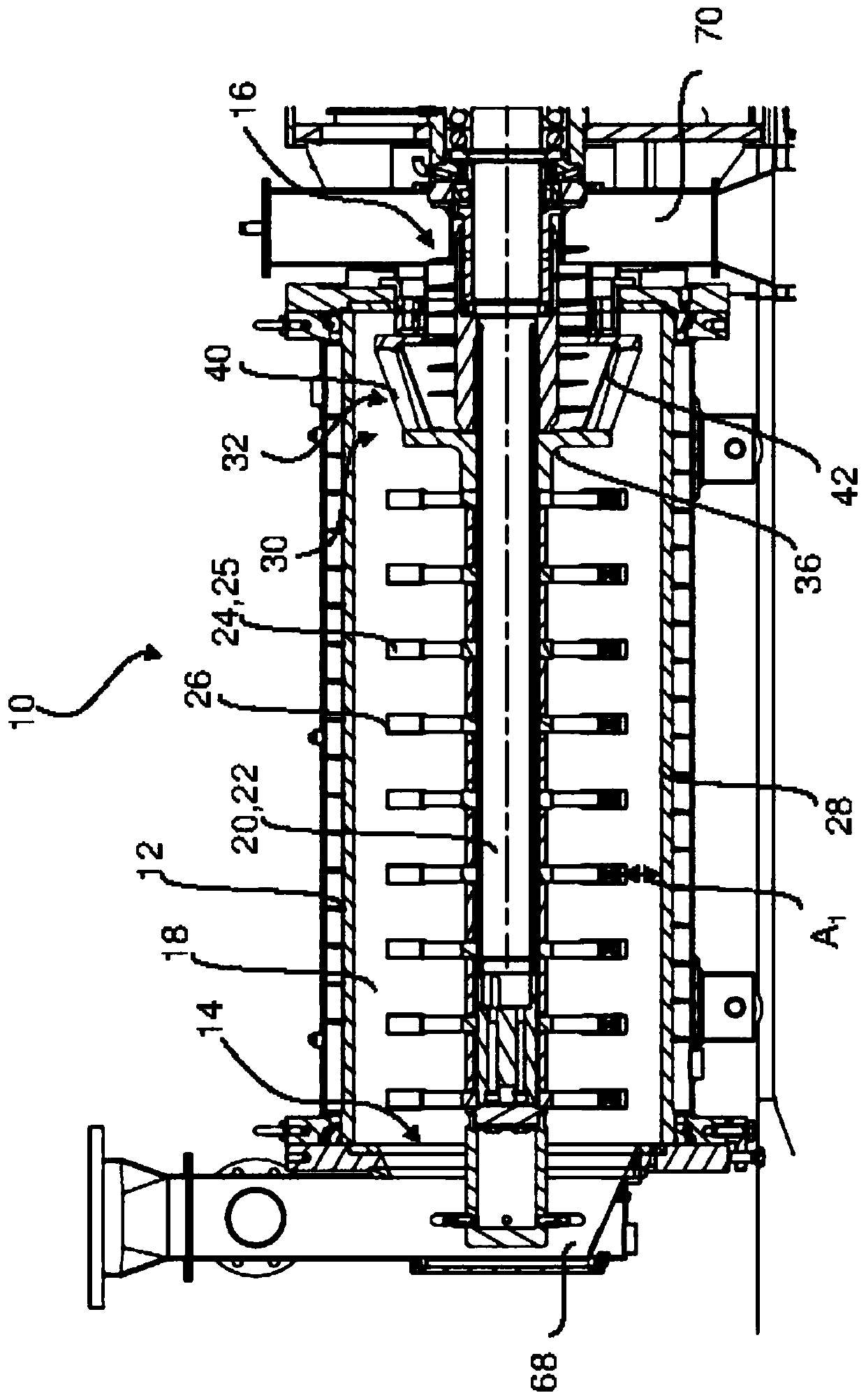

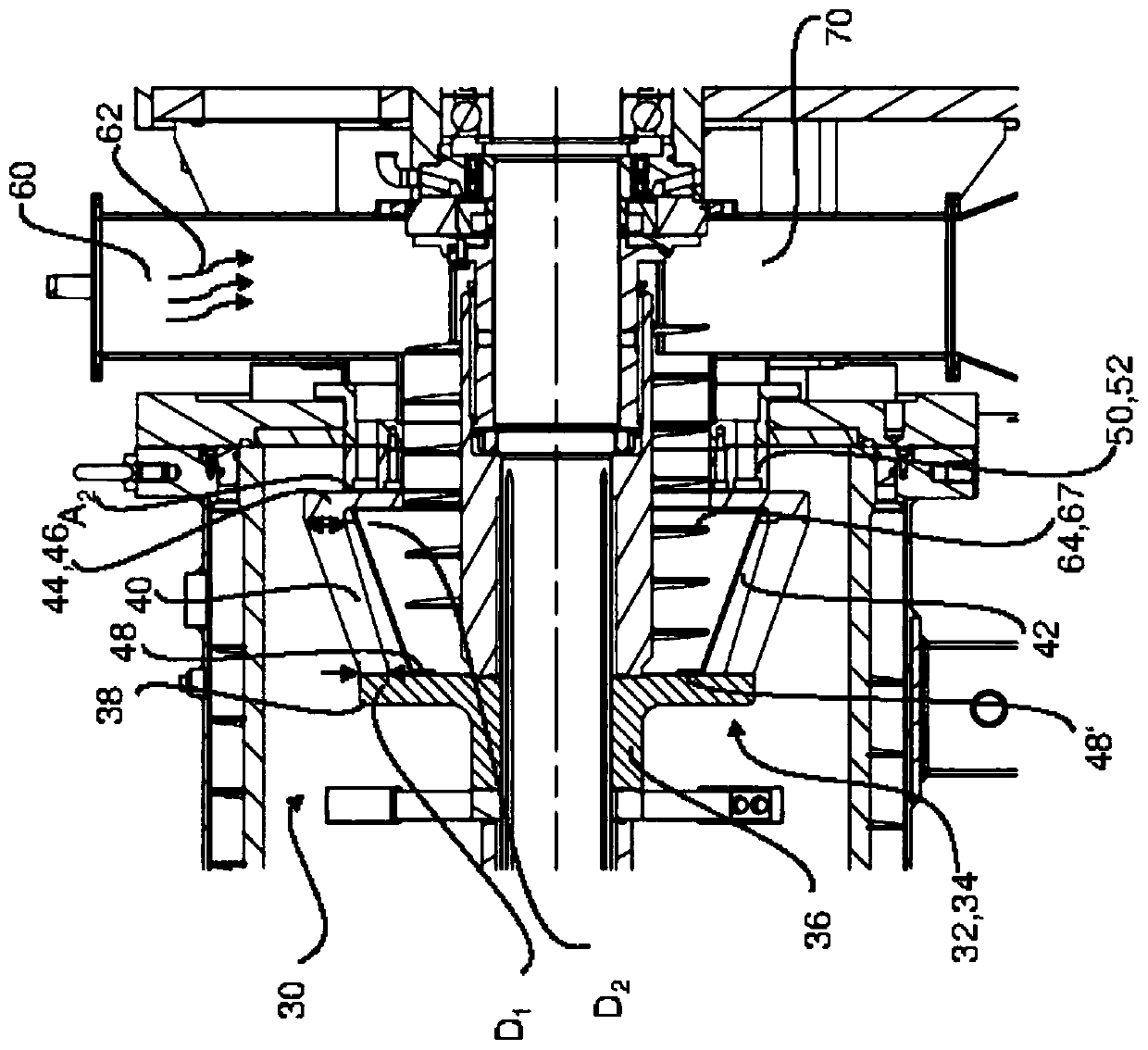

[0054] figure 1 A schematic diagram of a longitudinal section through an embodiment of an agitator ball mill 10 according to the invention is shown. The agitator ball mill 10 comprises a grinding vessel 12 which is configured cylindrically and is mounted horizontally. A low pressure exists in the grinding container 12 or in the grinding chamber 18 , which is provided by a suitable vacuum pump or the like, not shown here.

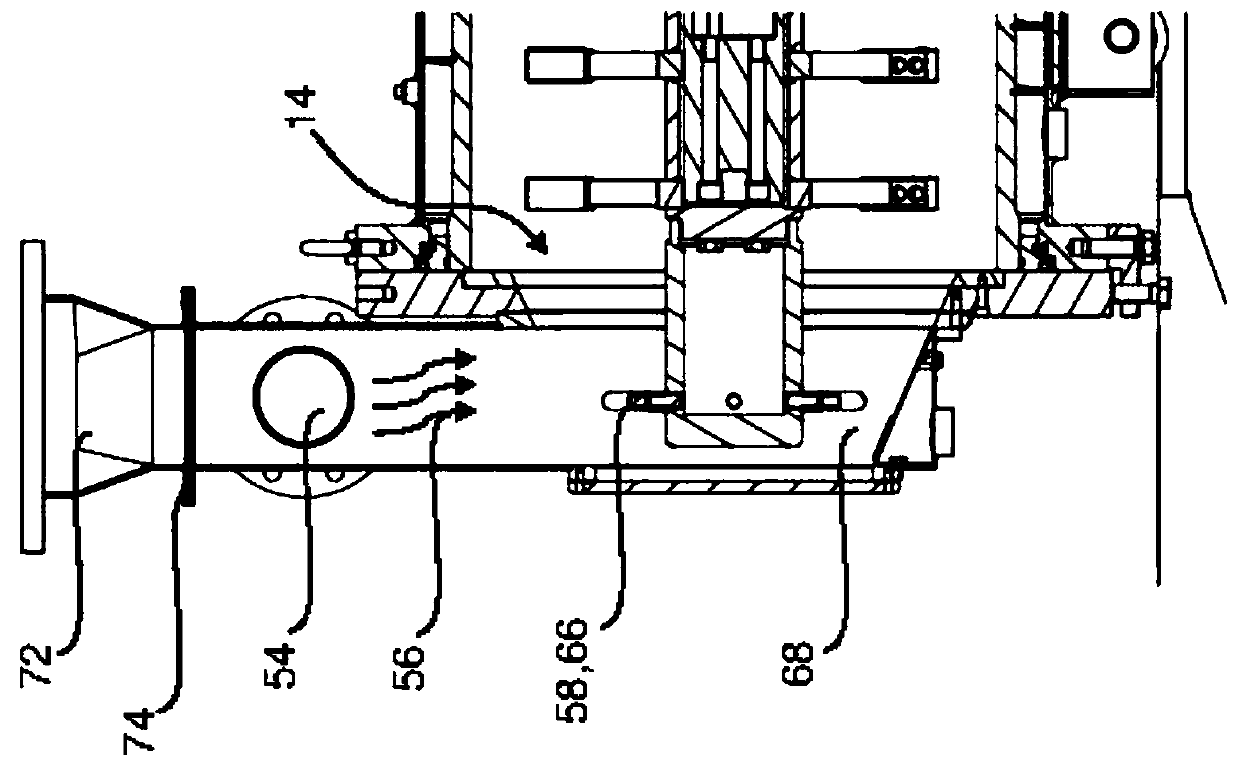

[0055] The grinding container 12 has a grinding material inlet 14 and a grinding material outlet 16 formed by corresponding openings in the grinding container 12 . The grinding material inlet 14 is arranged on the first end region of the grinding container 12 (at figure 1 on the left side in ) and the milling material outlet 16 is arranged on the opposite second end region ( figure 1 on the right side of the ). The milling material inlet space 68 is arranged spatially before the milling material inlet 14 (see figure 2 ). Furthermore, a ground material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com