Machining method for ball-head cylindrical ball-containing notch outer ring of double-column angular contact ball bearing

A double-row angular contact and ball filling notch technology, which is applied in metal processing equipment, manufacturing tools, grinding drive devices, etc., can solve the processing requirements of the outer ring of the ball head cylindrical ball filling notch that cannot meet the requirements of double row angular contact ball bearings and other problems, to achieve the effect of solving easy burns and large areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

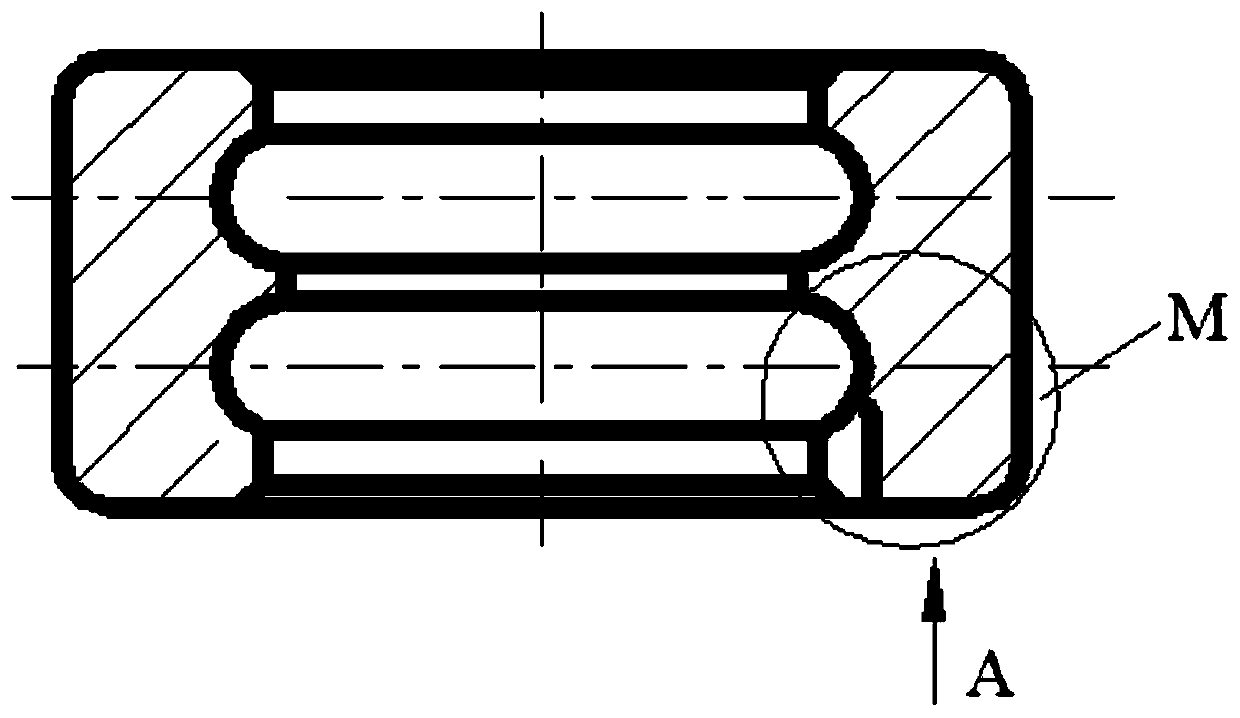

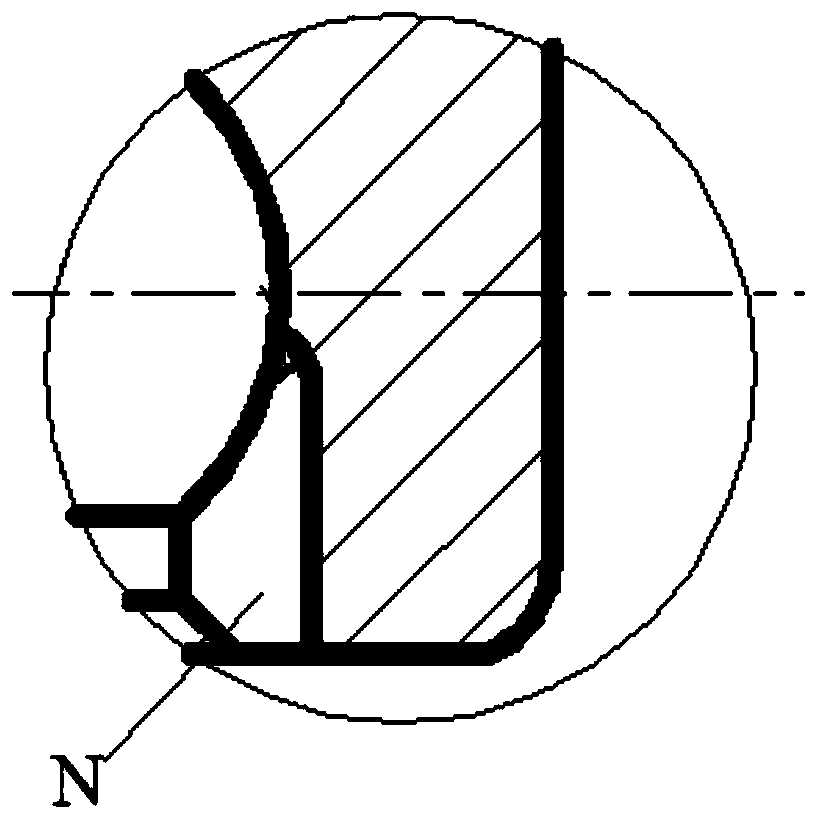

[0015] Specific implementation mode 1: This implementation mode is a method for processing the outer ring of the ball-end columnar notch of the double-row angular contact ball bearing, which is specifically completed according to the following steps:

[0016] 1. Preparation of notched parts to be processed: The bar material of the double row angular contact ball bearing to be processed is first fine-turned in turn according to the conventional processing method A side, fine-turned outer and inner diameter, inner and outer corners → fine-turned B-side, fine-turned outside Diameter, chamfering inner and outer corners → turning groove → straight slope on both sides of the car, chamfering inner corners → milling notch → deburring the notch → heat treatment → uniform rough grinding plane → final grinding plane → rough grinding outer diameter → final grinding outer diameter → fine grinding outer diameter → Coarse grinding of the outer groove → Final grinding of the outer groove → Rou...

specific Embodiment approach 2

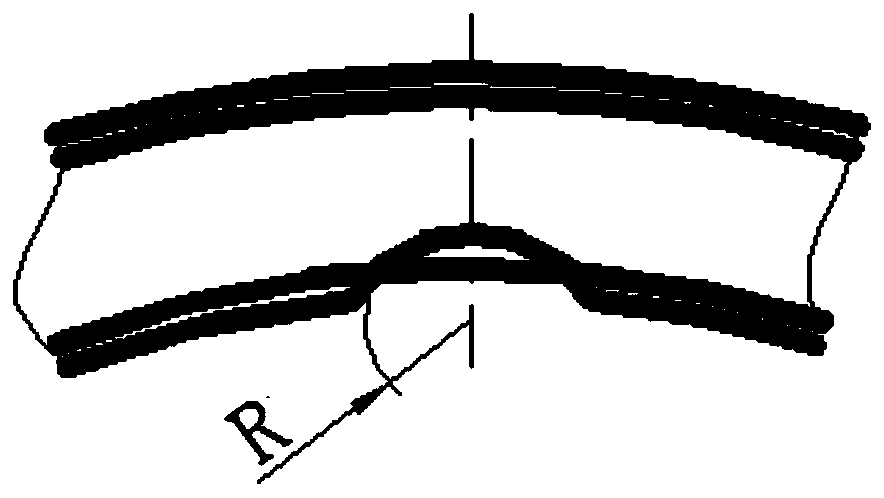

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 2, a diamond dressing tool is used to trim the front of the parallel grinding wheel into a ball head shape, and at the same time trim the outer diameter of the parallel grinding wheel. Others are the same as the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 2, 1 to 2 spiral grooves are formed along the outer surface of the grinding wheel after trimming. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com