Warehouse logistics goods automatic clamping carrier

A warehousing logistics and handling machine technology, which is applied in the field of cargo warehousing and logistics, can solve the problems of no clamping mechanism, inability to grasp multiple goods, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

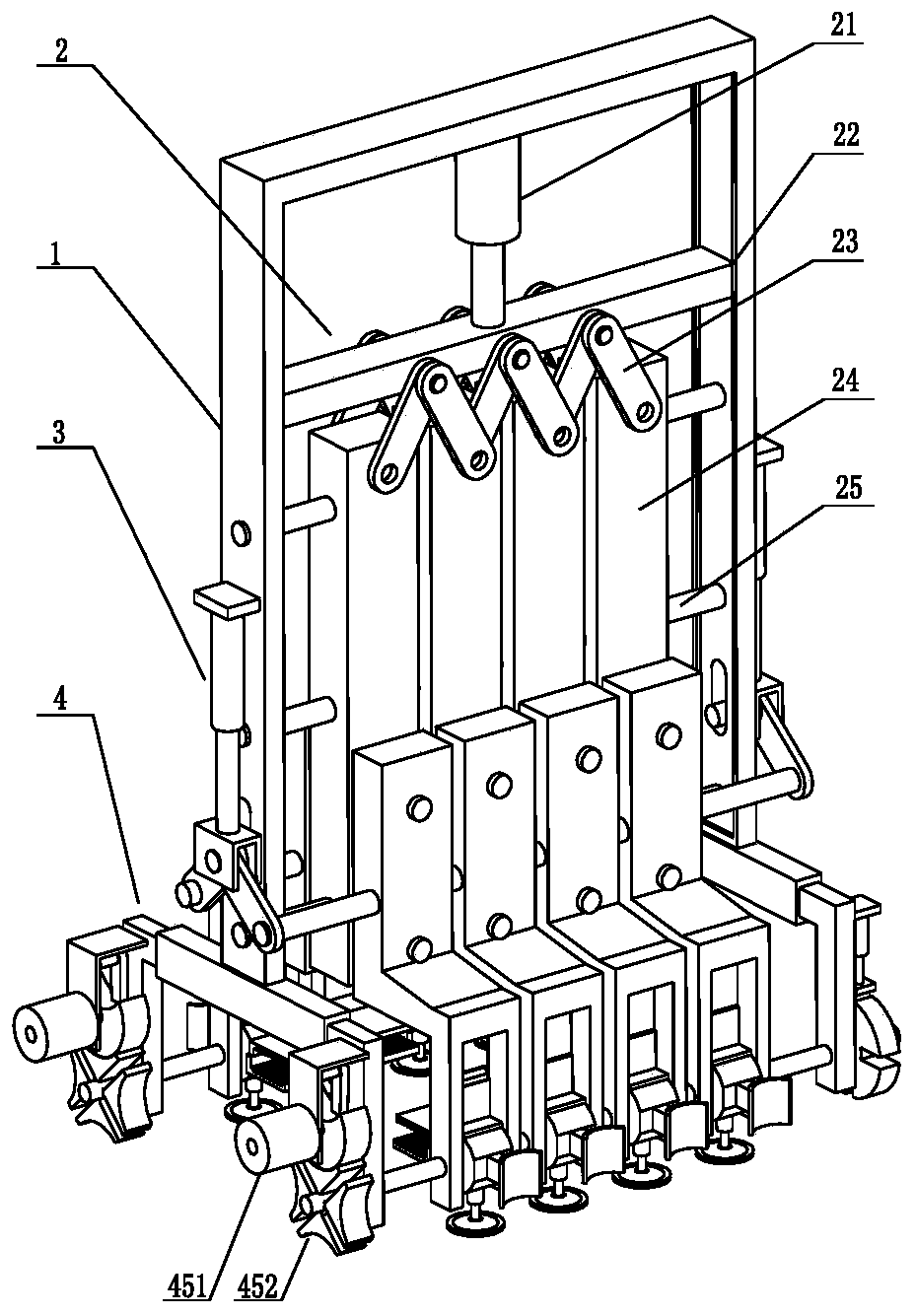

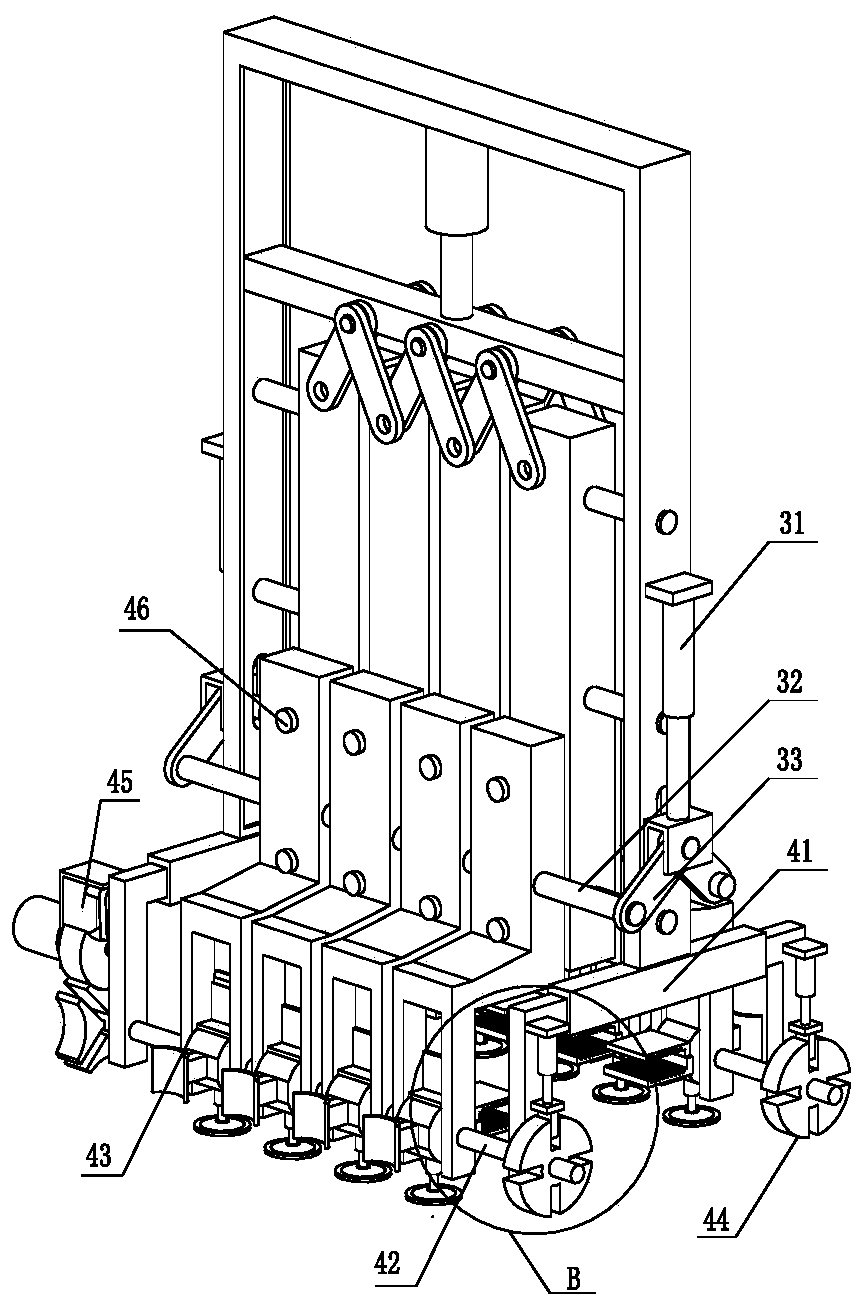

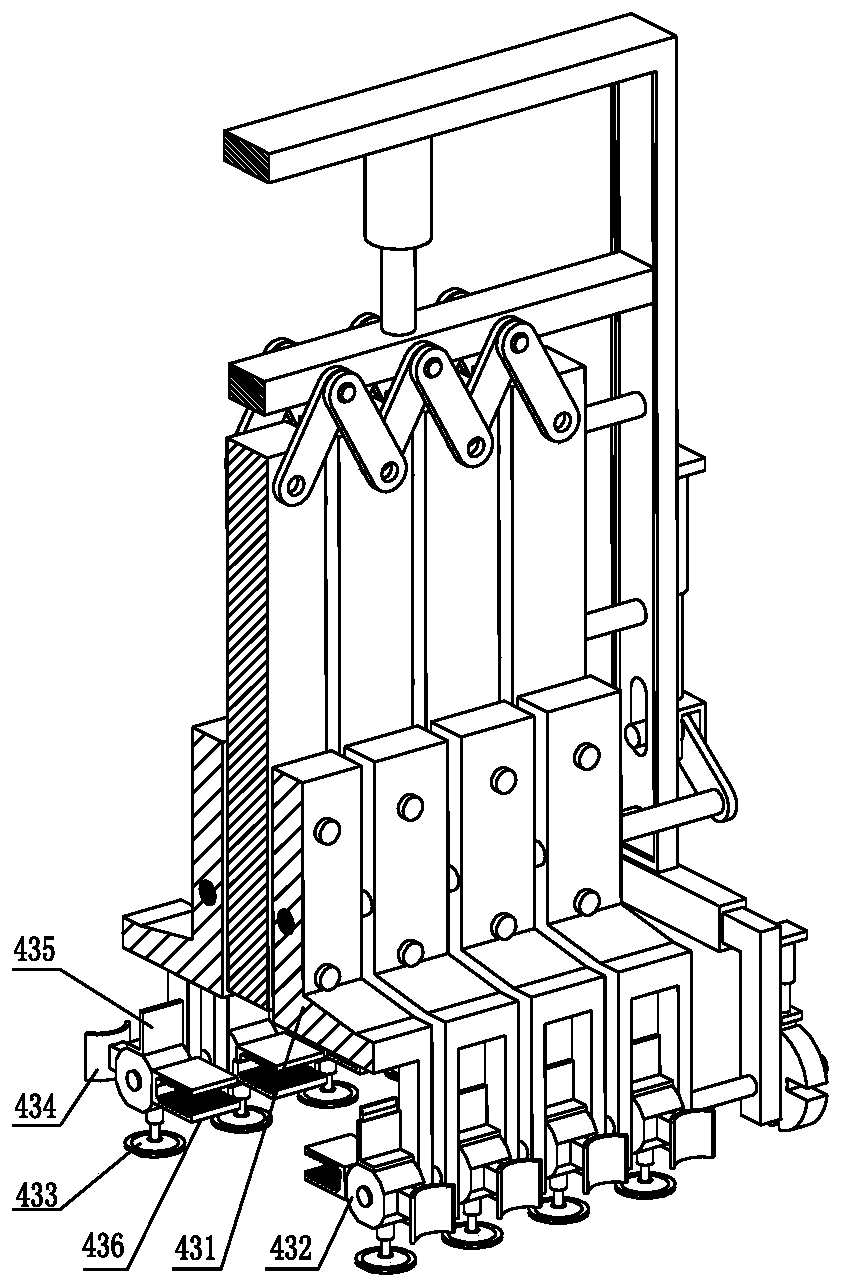

[0027] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 6 , to further elaborate the present invention.

[0028] An automatic clamping and handling machine for warehousing and logistics goods, including a bracket 1, a lateral distance variable mechanism 2, a longitudinal distance variable mechanism 3 and two sets of gripper mechanisms 4: the bracket 1 is a U-shaped structure, and the bracket 1 is in the middle of the two side plates Horizontal distance variable mechanism 2 is installed, and vertical distance variable mechanism 3 is installed outside support 1 both sides plates, and bracket 1 bottom is provided with clamping claw mechanism 4 symmetrically front and back, and the mutual cooperation of horizontal distance variable mechanism 2 and longitudinal distance variable mechanism 3 can Realize the gripping function of the claw mechanism 4 on goods o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com