Material arrangement device and conveying equipment

A material distributing device and technology for conveying materials, which is applied in the direction of conveyor objects, transportation and packaging, and slideways, etc., can solve the problems of easy tumbling of materials, low flexibility of conveying devices, and collisions, so as to reduce tumbling and collisions and improve flexibility of use sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

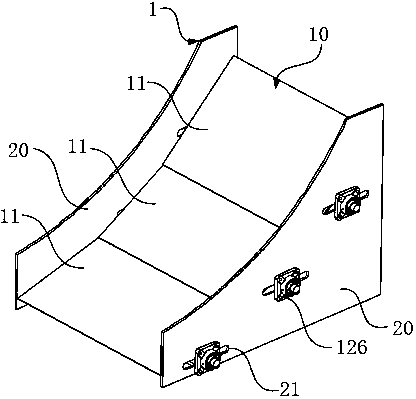

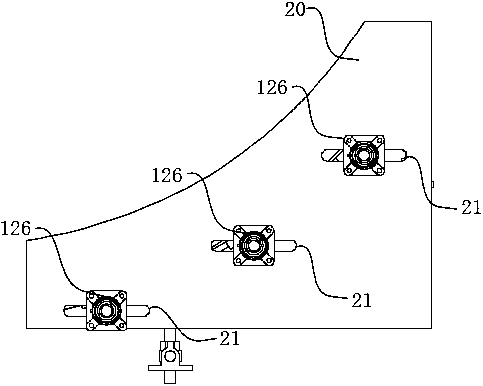

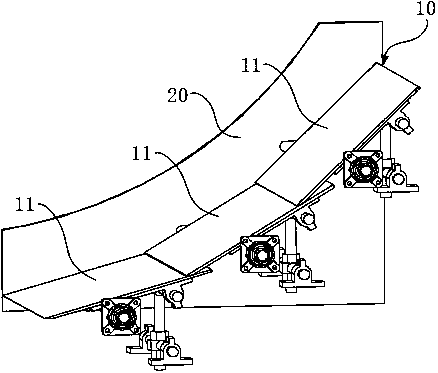

[0045] Such as Figure 1-Figure 3As shown, the distributing device provided in this embodiment is used to convey materials from a high place to a low place, and includes a conveying slide 1, and the conveying slide 1 has a rolling surface for supporting materials; the conveying slide 1 includes multiple Assembled slide mechanism 10; each slide mechanism 10 includes a slide 11, and the corresponding slides 11 in multiple slide mechanisms 10 can be spliced along the conveying direction of the material to form a rolling surface; between any adjacent slides 11 It has an included angle, and the size of the included angle can be adjusted, which is used to adapt the rolling surface to the movement track of the material along the conveying direction.

[0046] In this embodiment, the distributing device is applied between two conveying devices with a height difference, that is to say, it is used to convey materials from a high place to a low place, so that the materials can generate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com