Annealing furnace heating device for producing liquid crystal glass

A technology of heating device and liquid crystal glass, which is applied in the field of liquid crystal glass production equipment, can solve the problems that the temperature field of the annealing furnace cannot be stabilized, the structure of the heating device is complicated, and the connection of the furnace body is not tight, etc., so as to achieve simple structure, easy manufacture, and improved safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

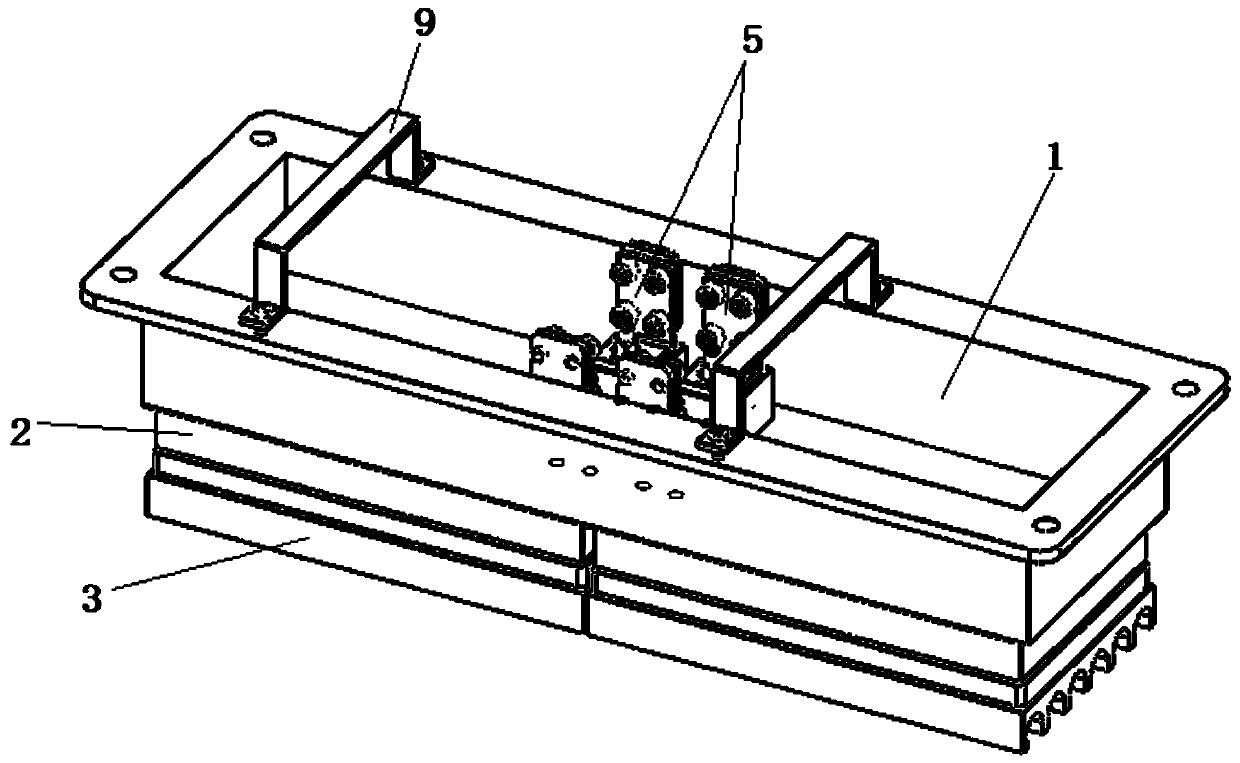

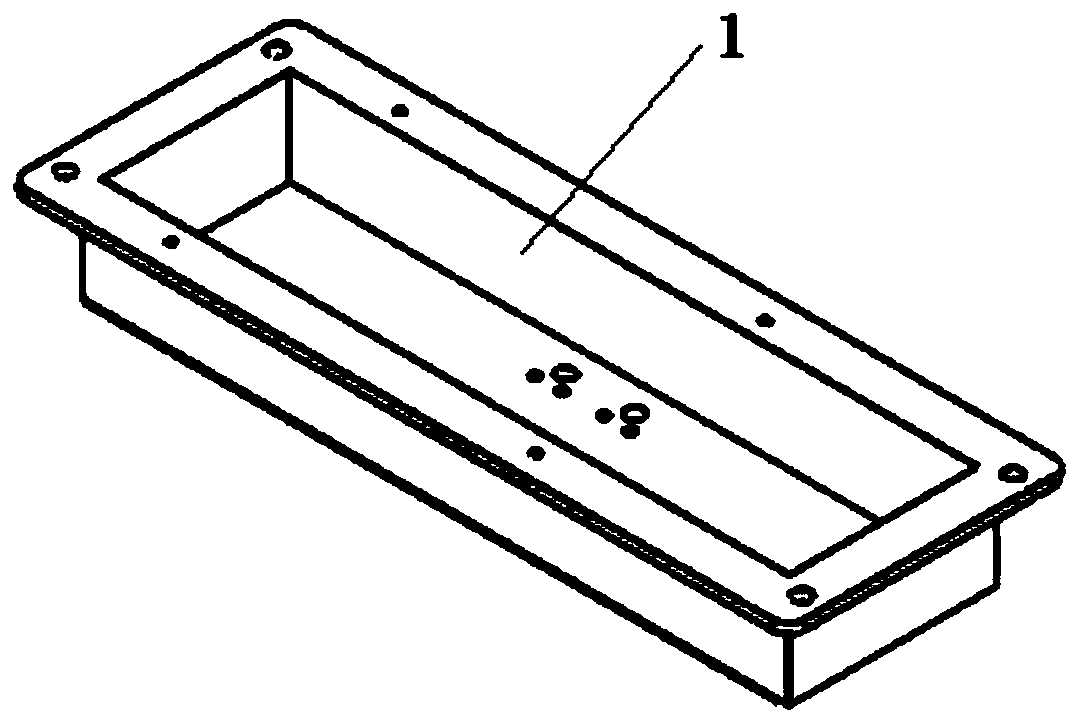

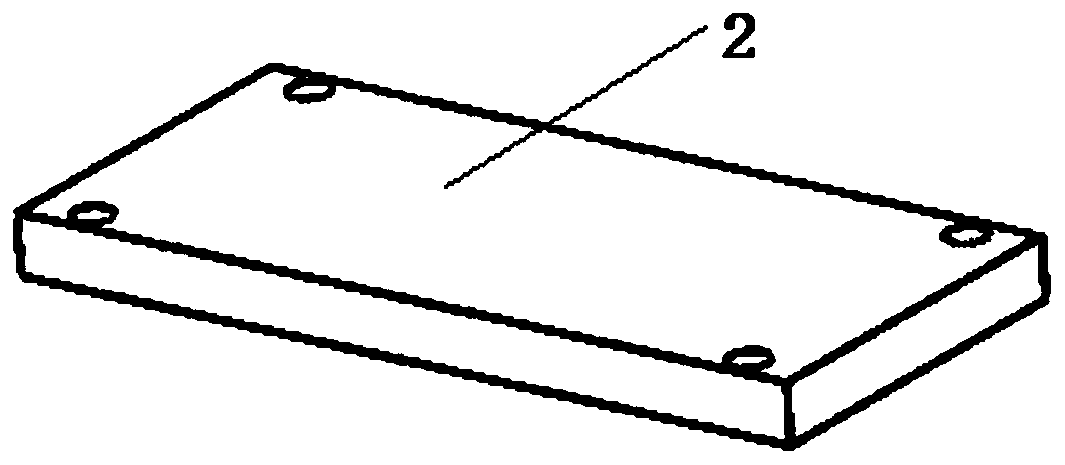

[0037] Such as figure 1 , 4 , shown in 5, a kind of annealing furnace heating device that is used to produce liquid crystal glass, comprises base 1, and the insulating brick 2 that is fixed on the bottom surface of base 1; Several grooves 31 are provided, and the furnace wire 4 is fixedly installed in the groove 31; several wiring seats 5 are fixed in the base 1, and the two ends of the furnace wire 4 are connected to the wiring socket 5; The ceramic base 51 , the first connecting terminal 52 fixed on the connecting ceramic base 51 , and the second connecting terminal 53 fixed on the first connecting terminal 52 . A handle 9 is fixedly installed on the edge of the upper part of the base 1 . The furnace pan 3 is also provided with a furnace wire fixing hole, and the high-temperature-resistant thin steel wire passes through the furnace wire fixing hole to fix the furnace wire 4 in the groove 31 on the furnace pan 3, and the furnace wire is fixed with the cement made of alumina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com