Annular mist spray dust removal device

A dust removal device and ring-shaped technology, which is applied in safety devices, dust prevention, mining equipment, etc., can solve problems such as poor dust removal effect, and achieve the effects of protecting the health of employees, high promotion value, and good dust reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

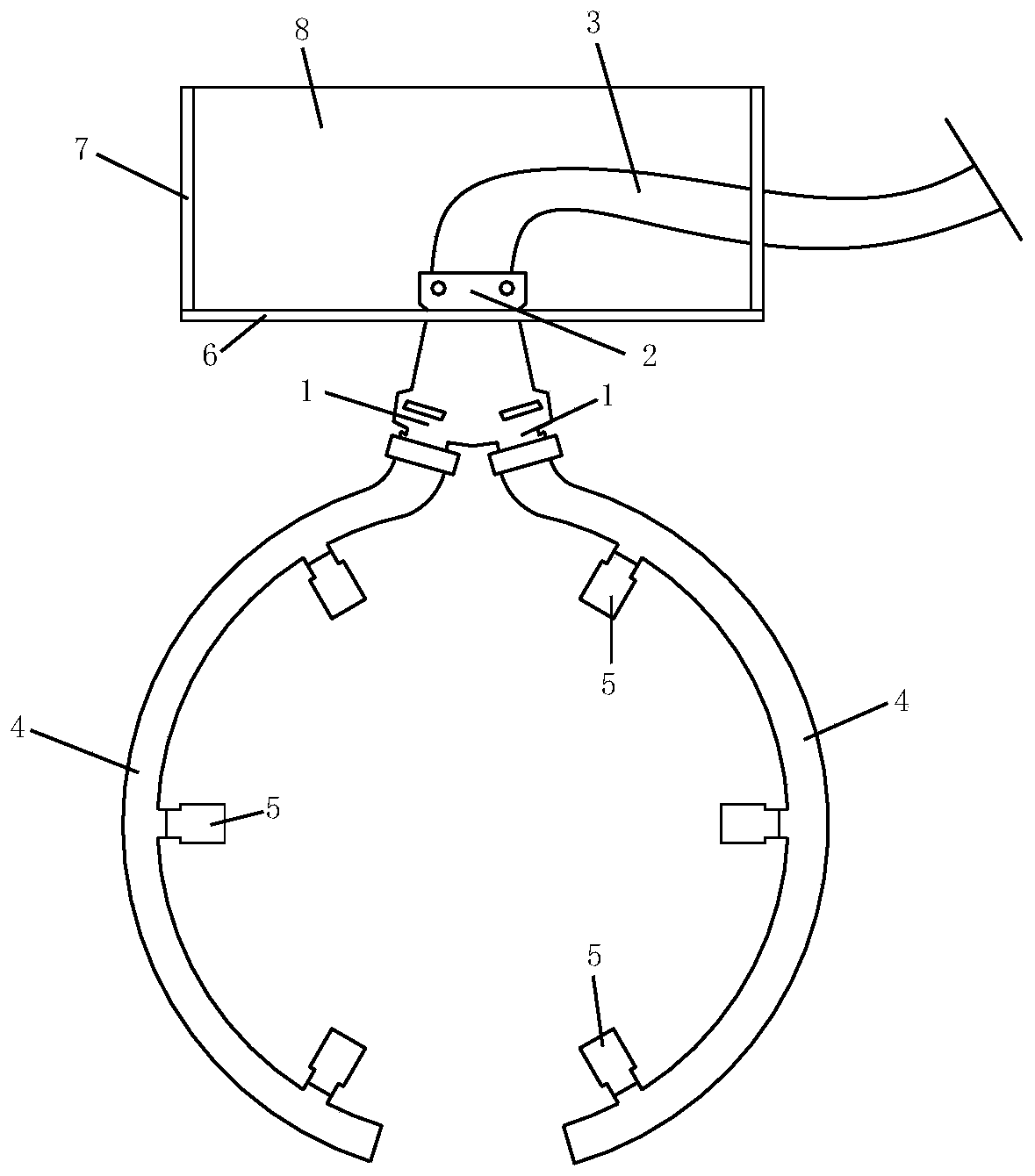

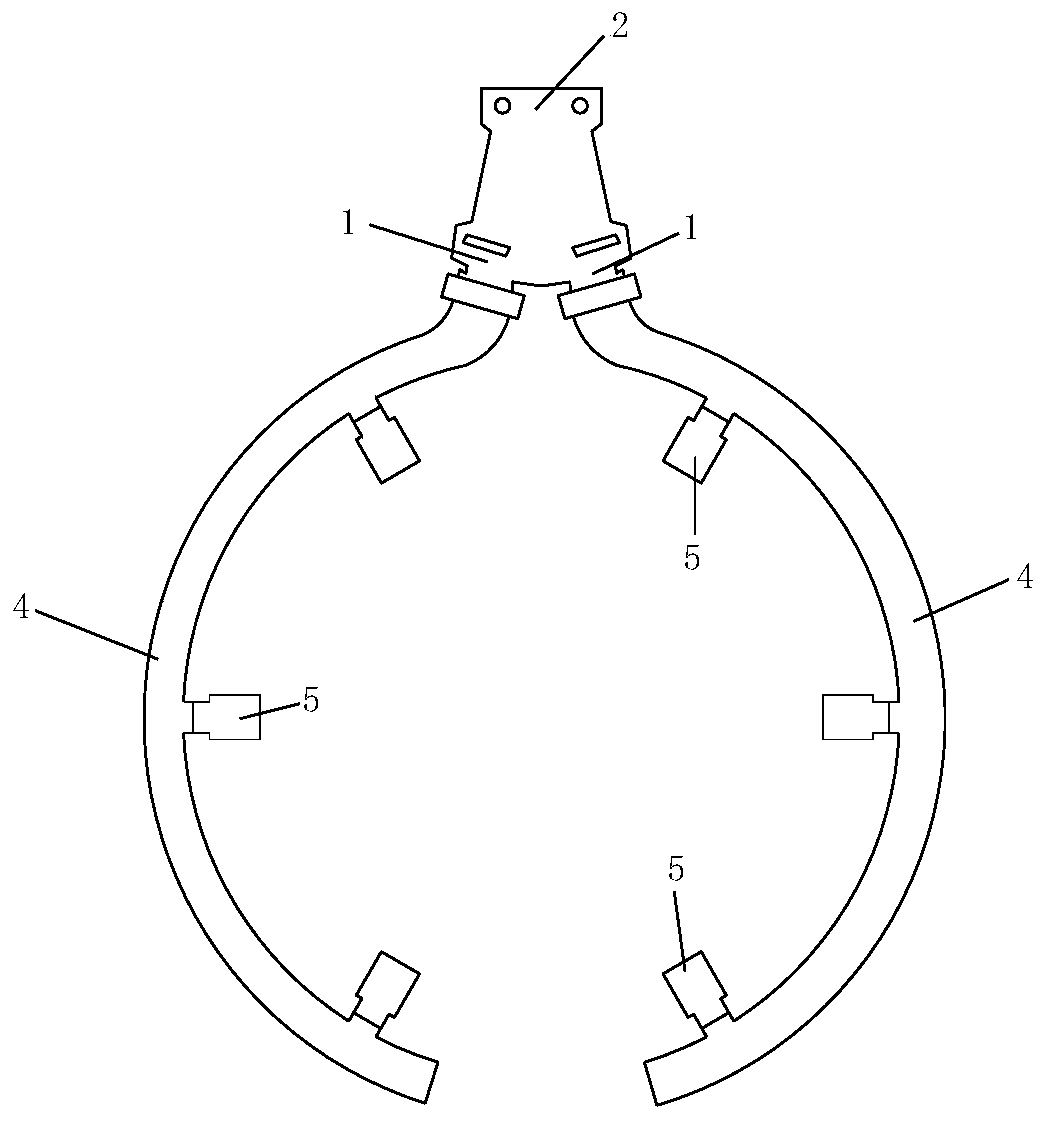

[0023] to combine Figure 1 to Figure 3 , an annular spray dedusting device, comprising an annular spray structure and a fixed frame structure.

[0024] The annular spray structure includes a three-way joint, and the three-way joint includes two oblique ports 1 .

[0025] Specifically, the three-way joint is inverted Y-shaped, the upper part of the three-way joint is the main interface 2, the main interface is connected to the water inlet pipe 3, the inclined interface 1 is arranged at the lower part of the three-way joint, and the two inclined interfaces are arranged opposite to each other.

[0026] The water inlet pipe is threaded with the main interface, and the arc pipe is threaded with the oblique interface. Of course, it can also be connected through other existing methods.

[0027] An arc-shaped tube 4 is connected to the oblique interface 1, and the arc-shaped mouths of the two arc-shaped tubes face each other, and a plurality of nozzles 5 are arranged on the inside ...

Embodiment 2

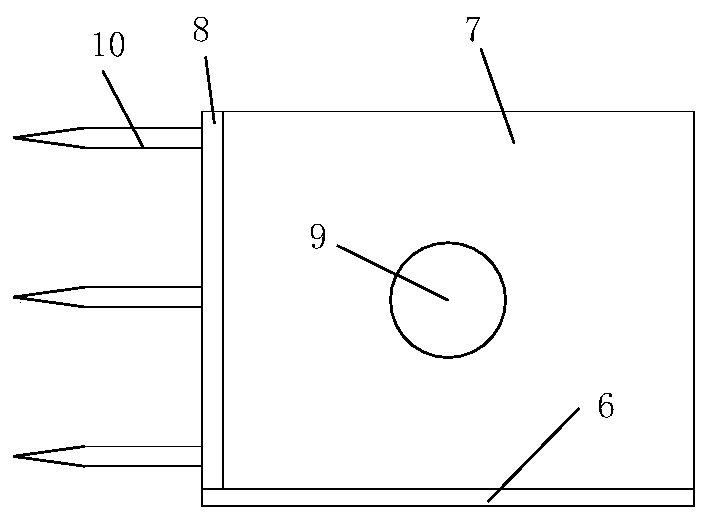

[0035] to combine figure 1 , figure 2 and Figure 4 , an annular spray dedusting device, comprising an annular spray structure and a fixed frame structure.

[0036] The annular spray structure includes a three-way joint, and the three-way joint includes two oblique ports 1 .

[0037] Specifically, the three-way joint is inverted Y-shaped, the upper part of the three-way joint is the main interface 2, the main interface is connected to the water inlet pipe 3, the inclined interface 1 is arranged at the lower part of the three-way joint, and the two inclined interfaces are arranged opposite to each other.

[0038] The water inlet pipe is threaded with the main interface, and the arc pipe is threaded with the oblique interface. Of course, it can also be connected through other existing methods.

[0039] An arc-shaped tube 4 is connected to the oblique interface 1, and the arc-shaped mouths of the two arc-shaped tubes face each other, and a plurality of nozzles 5 are arranged...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap