Waterproof penetration sleeve and construction method thereof

A technology of wall-piercing sleeves and wall-piercing pipes, which is applied in the direction of pipes, pipes/pipe joints/pipe fittings, mechanical equipment, etc., which can solve the problems of uneven filling space of sealing materials, large space occupation, complicated production process, etc., and achieve The production process is simple and reliable, the effect of saving support materials and saving transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

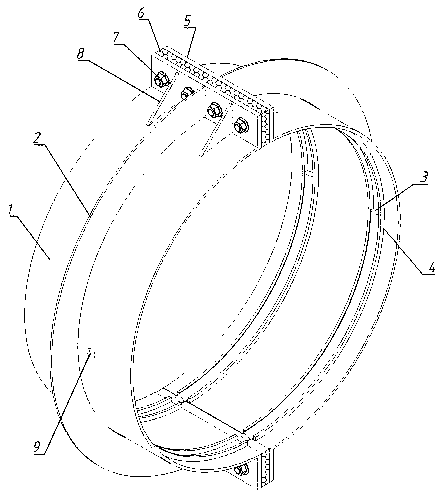

[0028] Embodiment 1: As shown in the accompanying drawings, the present invention provides a waterproof wall-penetrating casing, including casing (1), wing ring (2), flexible water stop ring (3), retaining ring (4), and connecting plate (5), flexible cushion (6), bolt connector (7), reinforcing rib (8), pressing hole (9), characterized in that the wing ring (2) and the sleeve (1), The connection plate (5) is welded, the retaining ring (4) is welded to the sleeve (1), the reinforcing rib (8) is connected to the connection plate (5), the sleeve (1) ) welding connection, the flexible cushion (6) and the connecting plate (5) are connected by the bolt connection (7), and the flexible water stop ring (3) is embedded in the retaining ring (4) to form a In the space, the pressure hole (9) is placed between the two flexible water stop rings (3).

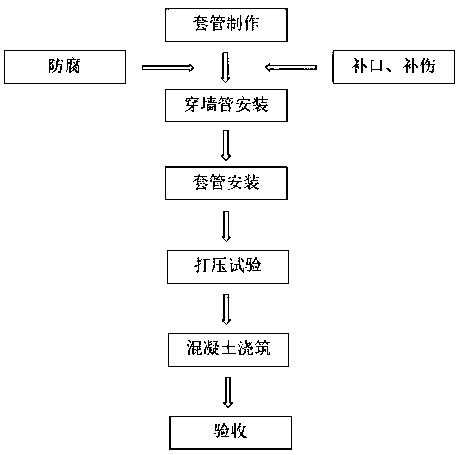

[0029] During construction, the specification, model, diameter, and length of the casing are determined according to the construction desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com