A Thin Film Capacitive Sensor

A capacitive sensor, thin-film technology, applied in the field of sensors, can solve problems such as temperature drift, different thermal expansion coefficients, and affecting the distance between the metal diaphragm and the ceramic fixed electrode, so as to improve reliability and avoid mechanical hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

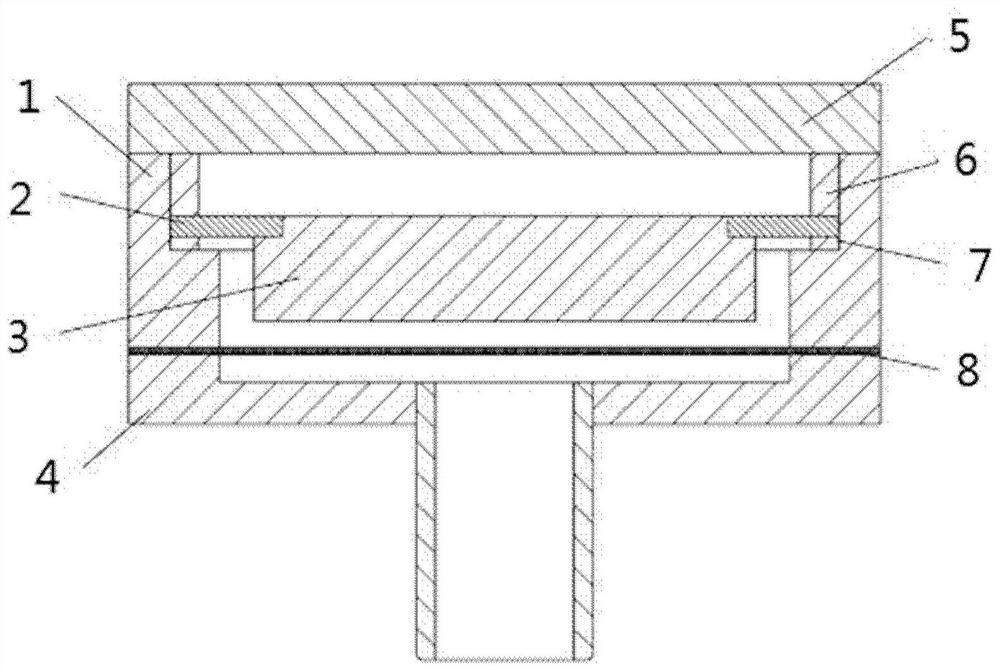

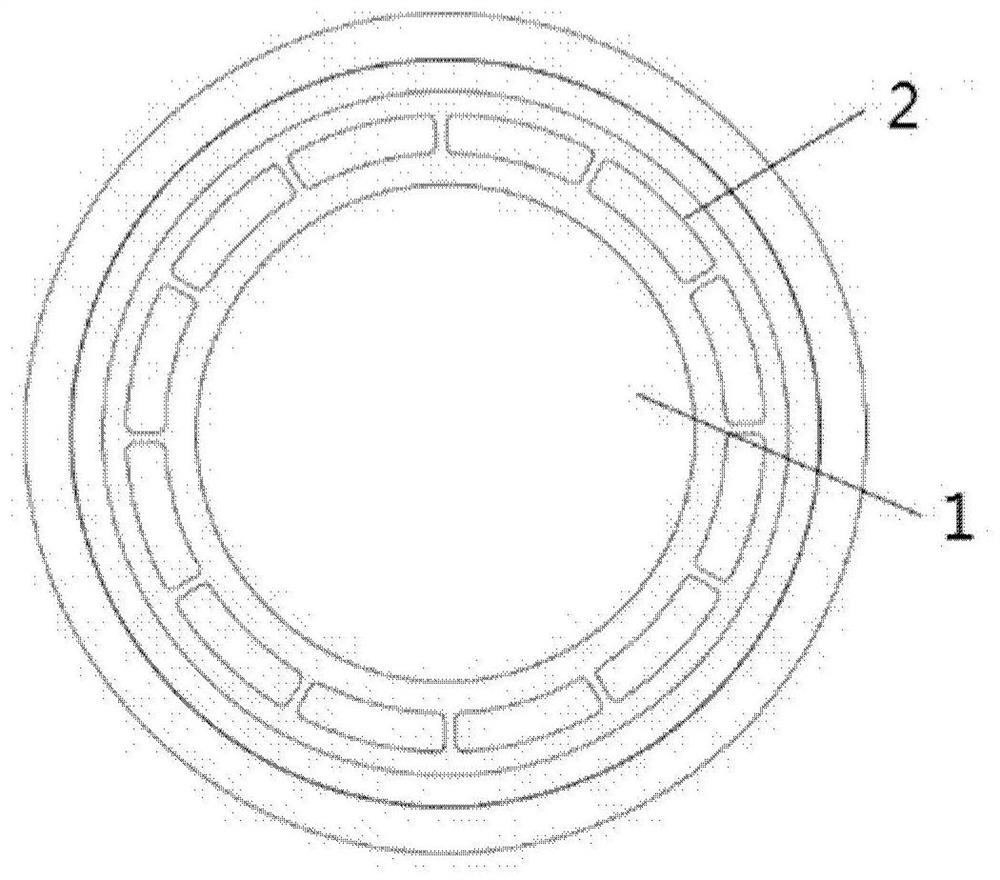

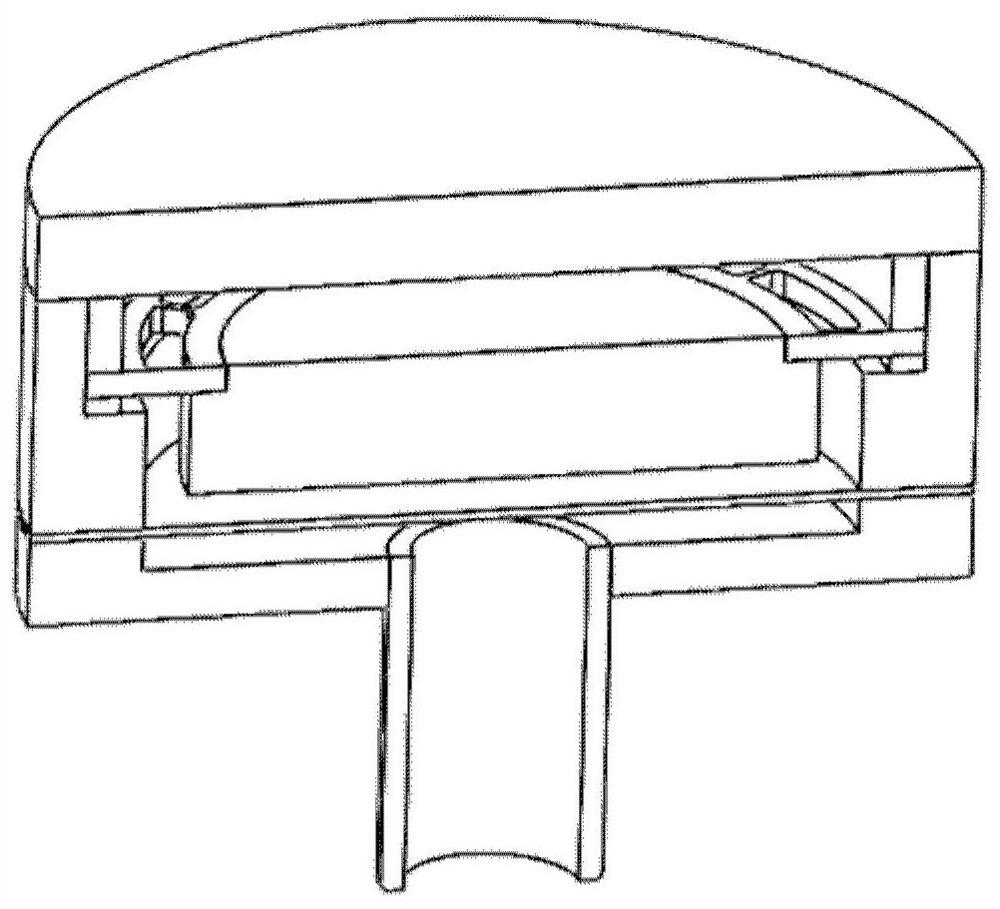

[0026] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a thin-film capacitive sensor according to an embodiment of the present invention. The thin-film capacitive sensor includes a ceramic fixed electrode 3, a fixed electrode connection ring 2, a casing cover 5, a compression ring 6, an adjustment ring 7, and a diaphragm movable electrode 8 and shell 1, where:

[0027] The ceramic fixed electrode 3 is used as a capacitive plate, and the diaphragm forms a variable capacitor, which is used to detect and output changes in the pressure of the measured environment.

[0028] The fixed electrode connecting ring 2 is used as a medium for connecting the ceramic fixed electrode 3 and the casing 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com