Railway tunnel leakage long-distance distributed monitoring method based on self-heating optical cable

A distributed monitoring, self-heating technology, applied in the application of light to test fluid tightness, by detecting the appearance of fluid at the leak point, and using liquid/vacuum for liquid tightness measurement, etc., can solve the problem of incompetence and high labor costs. , low monitoring efficiency, etc., to achieve the effect of slow heating rate, guaranteed automation, and reduced monitoring costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A new high-speed railway tunnel, the mileage of the implementation section of the present invention is DK49+430~DK51+430, 2km in total, and there is an evacuation shaft directly leading to the ground from the tunnel at DK50+430, and an equipment room is provided in the evacuation shaft.

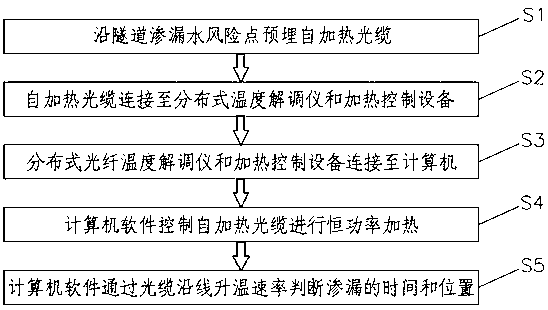

[0041] A long-distance distributed monitoring method for railway tunnel leakage based on self-heating optical cable, comprising the following steps:

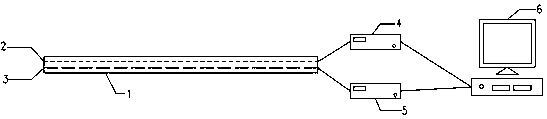

[0042] (i) Pre-buried self-heating optical cable 1 at water leakage risk points along the tunnel

[0043] In view of the fact that the implementation object itself is an open-cut high-speed railway tunnel, the important risk points of the vault directly above the left and right lines of the line and the leakage of tunnel deformation joints are judged, and the self-heating optical cable 1 is pre-embedded in the left and right lines of the vault during the construction process. directly above and embedded in the deformation seam. The pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com