Rotatable dustproof insulator

A technology of insulators and rotating sleeves, applied in the direction of insulators, electrical components, circuits, etc., can solve the problems of inability to deal with rainwater and dust, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

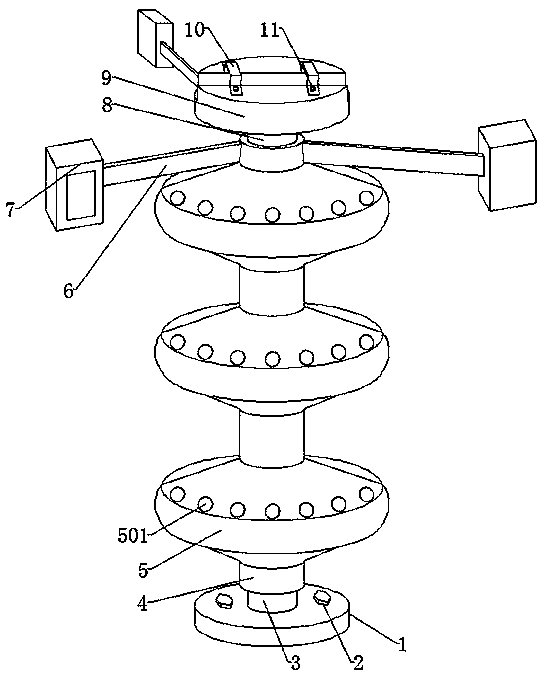

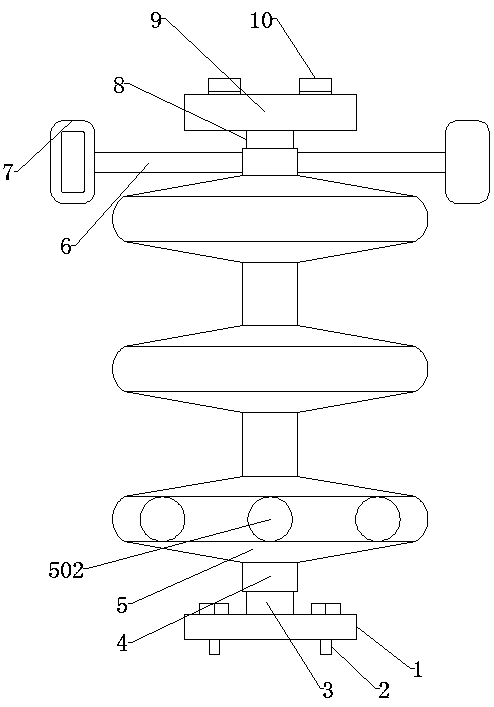

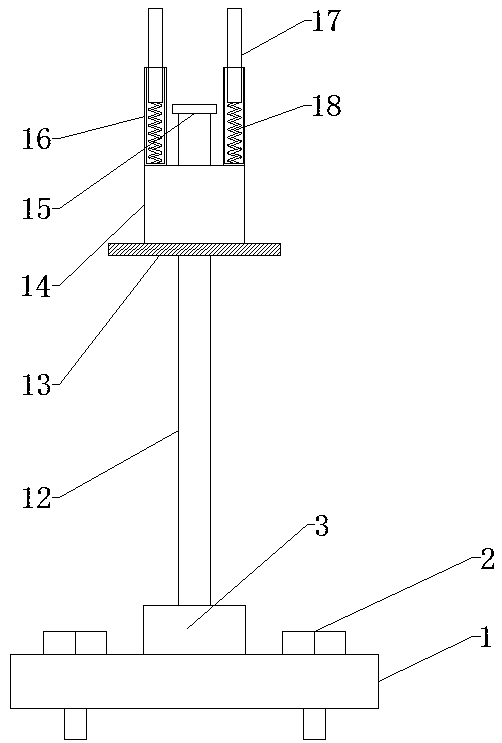

[0029] refer to Figure 1-5 , a rotatable dust-proof insulator, including a base 1, a fixed block 3 is welded in the middle of the top end of the base 1, a rotating sleeve 4 is provided on the outer wall of the fixed block 3, and a fixed block 3 is welded on the top end of the fixed block 3. A reciprocating screw rod 12, the outer cover of the reciprocating screw rod 12 is provided with a rotating block 14, the bottom end of the rotating block 14 is welded with a rubber plate 13, and the rubber plate 13 is slidably connected with the inner wall of the rotating sleeve 4. The top end of the rotating sleeve 4 is provided with a first through hole, the rotating sleeve 4 is rotatably connected with a connecting sleeve 8 at the first through hole, and the top end of the connecting sleeve 8 is welded with a fixed disk 9 .

[0030] In the present invention, the top of the rotating block 14 is welded with two fixed cylinders 16, and the tops of the two fixed cylinders 16 are provided w...

Embodiment 2

[0038] refer to Image 6 , a rotatable dust-proof insulator. Compared with Embodiment 1, in this embodiment, in order to have a certain range of motion between the line and the insulator, the bottom ends of both sides of the connecting sleeve 8 are welded with clamping blocks 19, Both sides of the top of the inner wall of the rotating sleeve 4 are provided with slideways, the block 19 is slidably connected with the rotating sleeve 4 on the slideway, and a second spring is welded between the bottom end of the connecting sleeve 8 and the rotating sleeve 4 20 , the block 19 can slide on the inner wall of the rotating sleeve 4 , and the connecting sleeve 8 can move within a certain range through the second spring 20 .

[0039] When in use, the device is fixed on the wire rack by the base 1 and the first screw 2, and the circuit can be fixed in the strip groove of the fixed disk 9 by the fixed piece 10 and the second screw 11. The plate 7 can drive the connecting rod 6 to rotate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com