Bus duct and bus duct joint thereof

A technology of busway and trapezoidal groove, which is applied in the direction of docking busbar, busbar installation, cooling busbar device, etc., which can solve the problems of easy temperature rise of connecting rod, heating of nut, need for regular tightening, etc., so that it is not easy to heat up and strengthen Heat dissipation, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

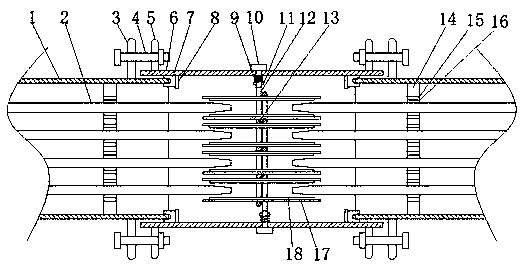

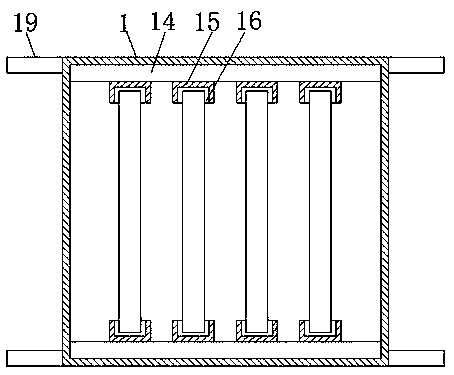

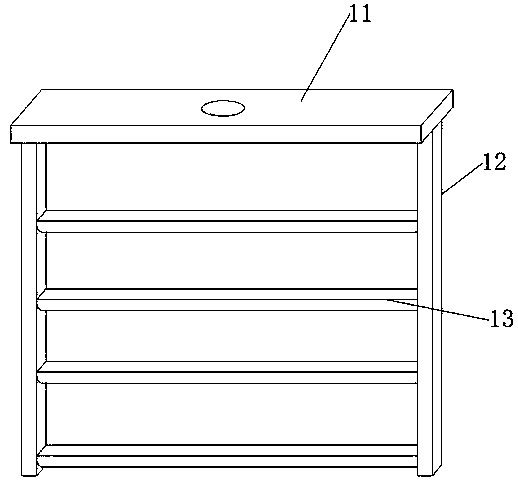

[0025] refer to Figure 1-3 , a bus duct and its bus duct connector, including two main bodies 1, the inside of the two main bodies 1 are provided with conductive bars 2, the top and bottom ends of one side of the conductive bar 2 are provided with inclined plane openings, the two main bodies 1 The outside of the protective cover 6 is provided with a circular through hole at the top and bottom of the protective cover 6, and the protective cover 6 is provided with fastening bolts 10 at the two circular through holes, and one end of the fastening bolt 10 is threaded A moving plate 11 is connected, and fixed rods 12 are welded on both sides of the moving plate 11. A moving rod 13 is welded between the two fixed rods 12. An insulating sheet 17 is arranged on the top of the moving rod 13, and the top of the insulating sheet 17 is bonded There is a conductive piece 18, when installing, twist the two fastening bolts 10, the fastening bolts 10 make the moving plate 11 move, the two mo...

Embodiment 2

[0035] refer to Figure 4 , a bus duct and its bus duct connector. Compared with Embodiment 1, in this embodiment, in order to increase the waterproof performance of the device, the sealing ring 7 is provided with a water-swellable water stop 20 on one side of the trapezoidal groove, When water seeps into the inside of the trapezoidal groove of the sealing ring 7, the water-swelling waterstop 20 will swell when meeting water, so that the sealing performance of the device is improved.

[0036] During installation, twist the two fastening bolts 10, the fastening bolts 10 will move the moving plate 11, and the two moving plates 11 will move away from each other, and the spring 9 will be compressed to provide an axial force for the fastening bolts 10, preventing the moving plate 11 falls off easily, the two moving plates 11 drive the moving rod 13 on the fixed rod 12 to move, and the moving rod 13 drives the insulating sheet 17 to move until both sides of the conductive sheet 18 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com