Heat dissipation protection device of electromechanical equipment

A technology for protection devices and electromechanical equipment, applied in electrical equipment structural parts, electrical equipment housings/cabinets/drawers, electrical components, etc., can solve the problems of high dust volume, easy damage of electronic components, easy accumulation inside the control cabinet, etc. , to achieve the effect of improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

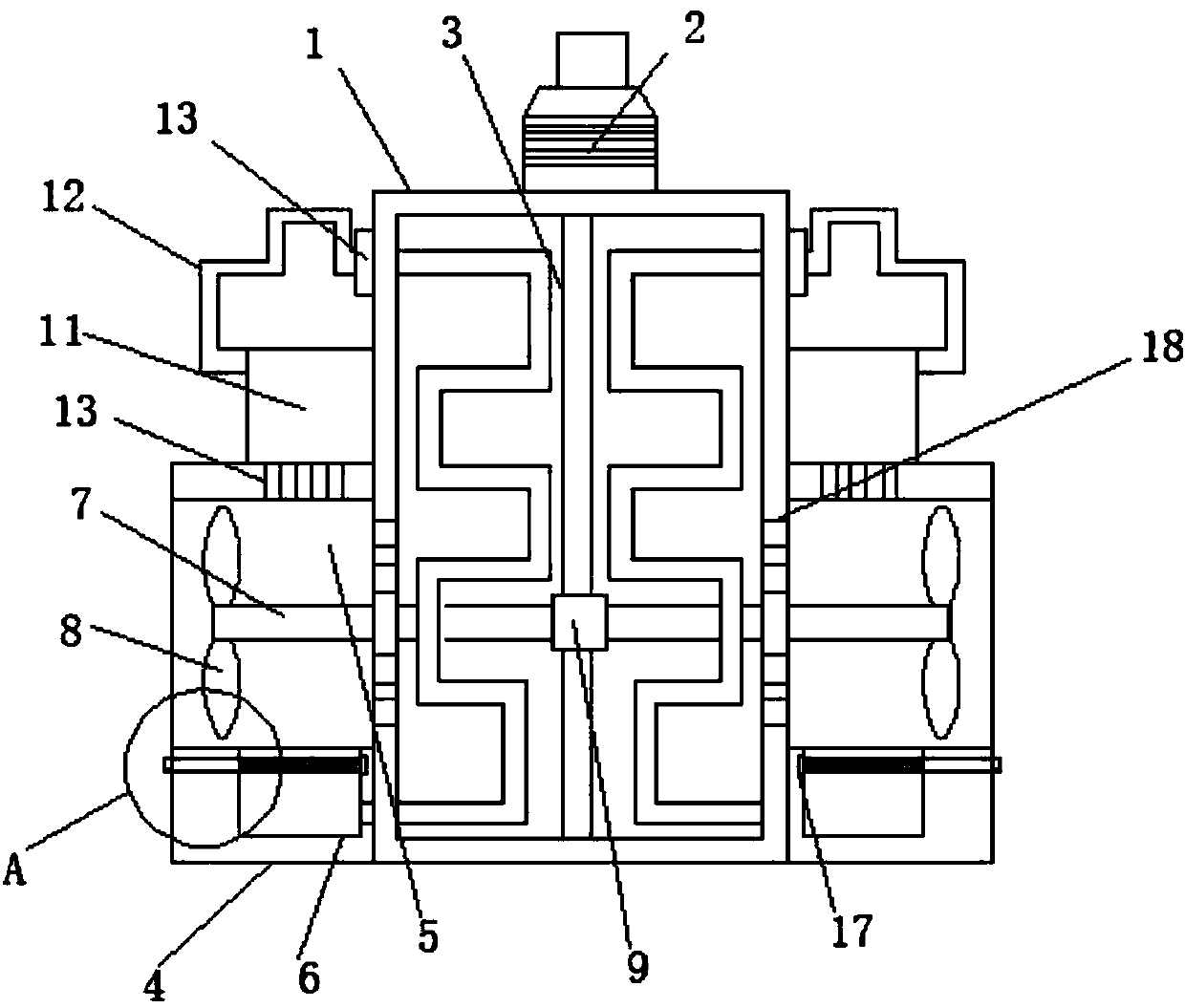

[0025] Example: refer to Figure 1-5 , a heat dissipation protection device for electromechanical equipment, including a cabinet body 1, a heat dissipation mechanism is provided on both sides of the cabinet body 1, a circulation mechanism is provided inside the cabinet body 1, and the top side wall of the cabinet body 1 A driving motor 2 is fixed, and the output shaft of the driving motor 2 is fixed with a rotating shaft 3 through a coupling. The end of the rotating shaft 3 away from the driving motor 2 extends to the bottom side wall of the cabinet body 1 for rotational connection. The two sides of the cabinet body 1 The walls are provided with a plurality of cooling holes 18 .

[0026] The heat dissipation mechanism includes a heat dissipation platform 4 fixed on the side walls of both sides of the cabinet body 1. The heat dissipation platform 4 is provided with a first through hole 5 penetrating left and right. The first through hole 5 communicates with the heat dissipation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com