A kind of preparation method of sticking type balance weight block

A balance block and paste-type technology, which is applied in the field of auto parts processing, can solve the problems of low utilization rate of raw materials, complicated rounding process, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

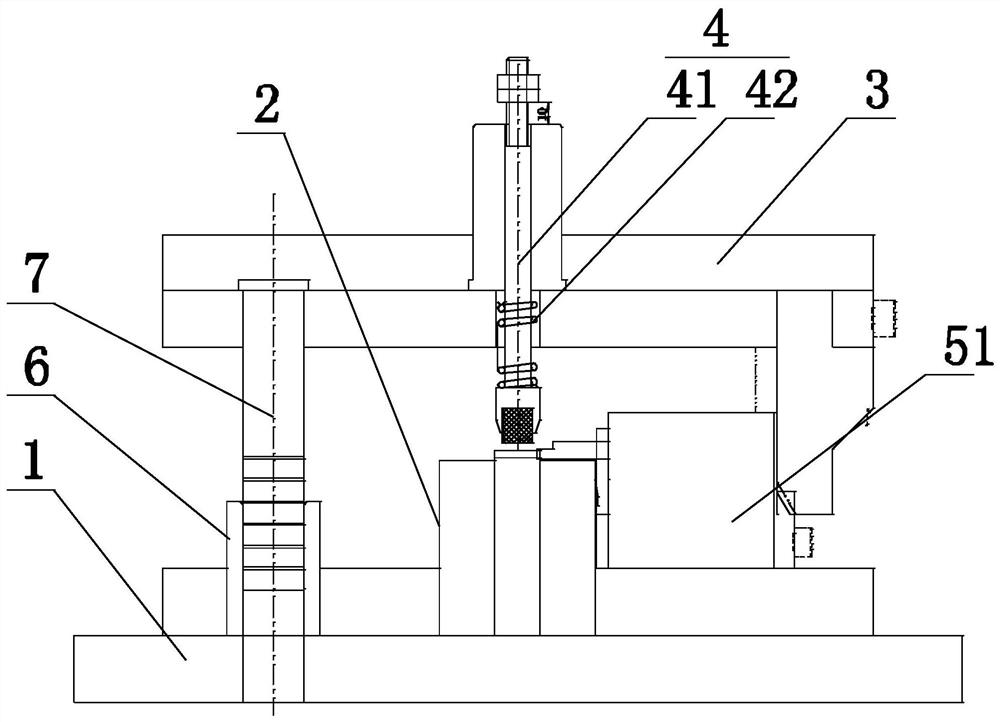

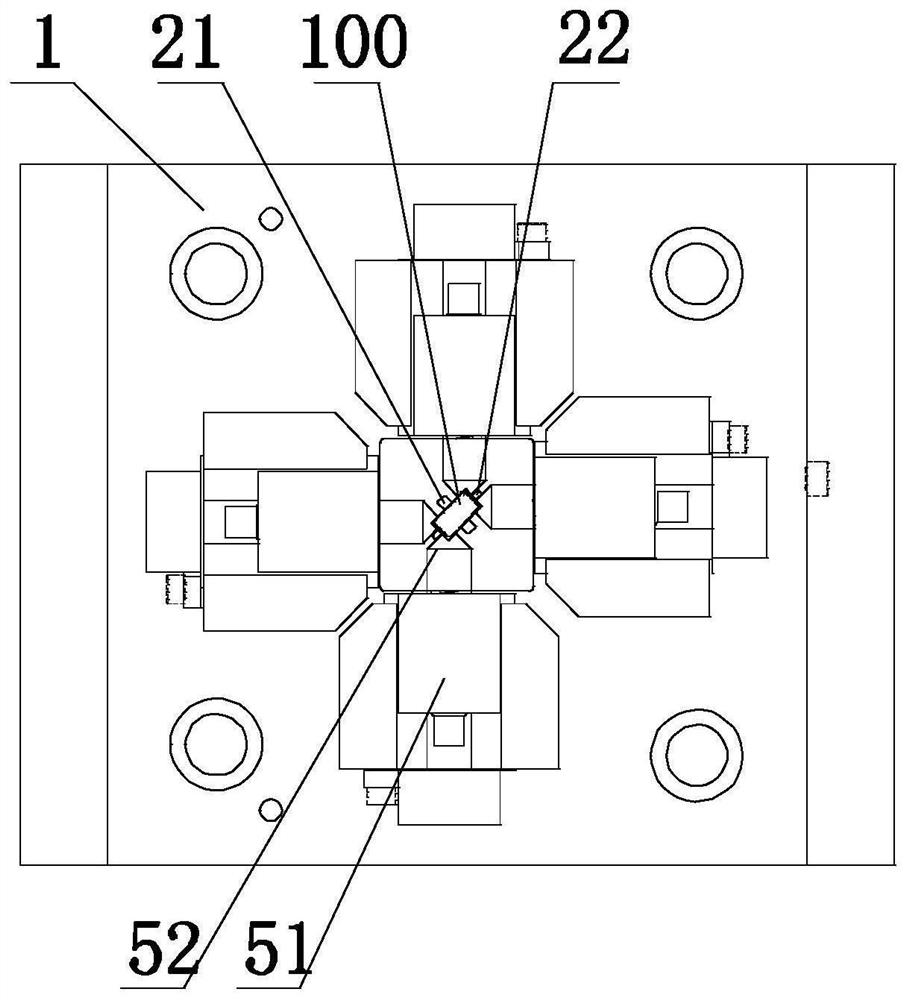

[0019] Such as figure 1 and 2 as shown, figure 1 It is a structural schematic diagram of a shaping device for a method for preparing a paste-type balance weight block proposed by the present invention, figure 2 It is a schematic plan view of the workbench of the shaping device of a method for preparing a paste-type balance weight body proposed by the present invention.

[0020] A method for preparing a paste-type balance weight block proposed by the present invention includes the following steps: punching a plate into a plurality of block base materials 100, and shaping the top corners of the block base materials 100 to form rounded corners.

[0021] In this embodiment, the proposed method for preparing the paste-type balance weight block is to punch the plate into multiple block base materials, and shape the top corners of the above block base materials to form rounded corners; the above-mentioned preparation method includes stamping The process and shaping process can ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com