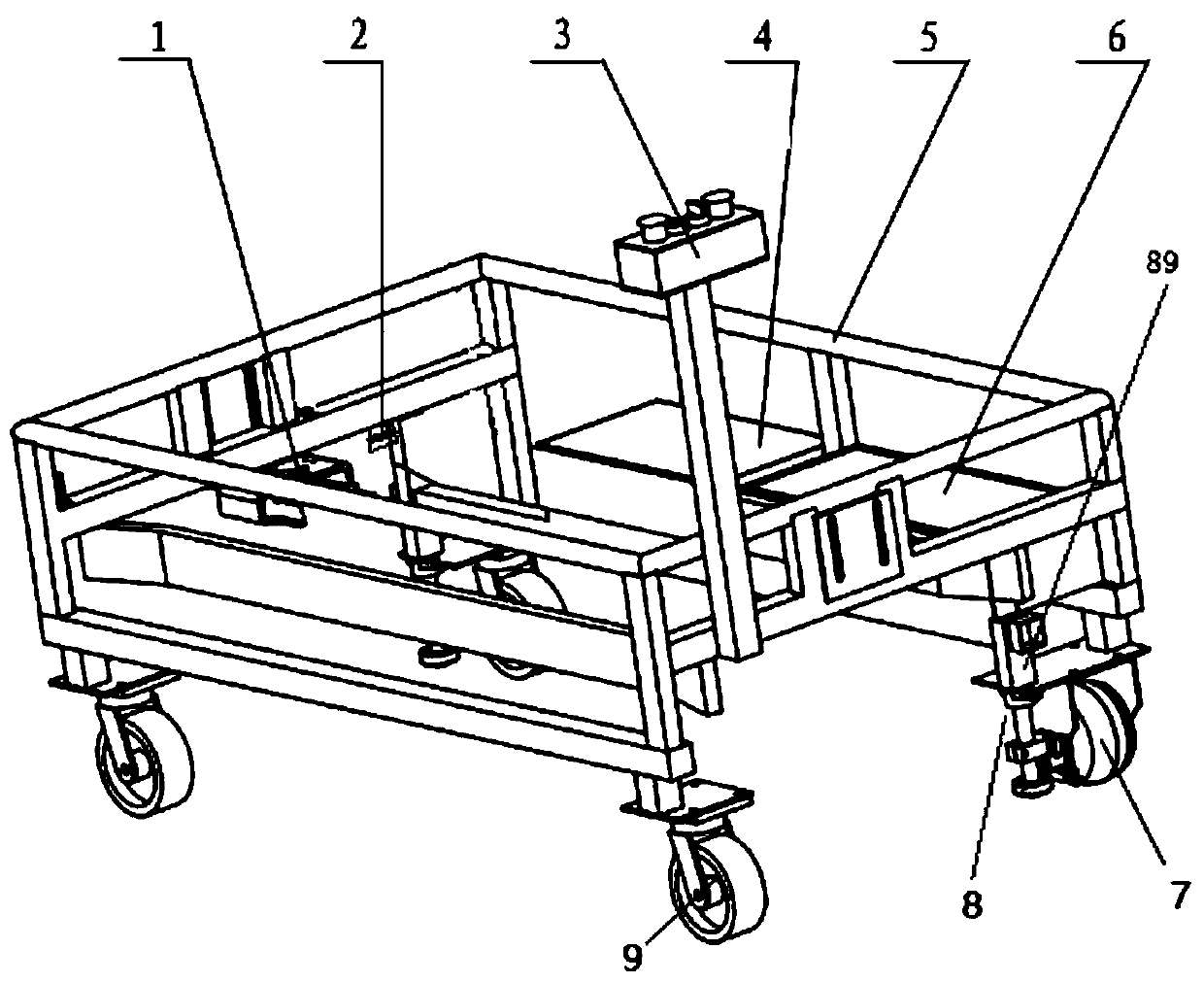

Simple automatic walking transport trolley and application thereof

A technology of automatic walking and transporting trolleys, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of engine misalignment, misplaced assembly parts, and staff walking around to pick up materials, etc., to buffer impacts, improve automation, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

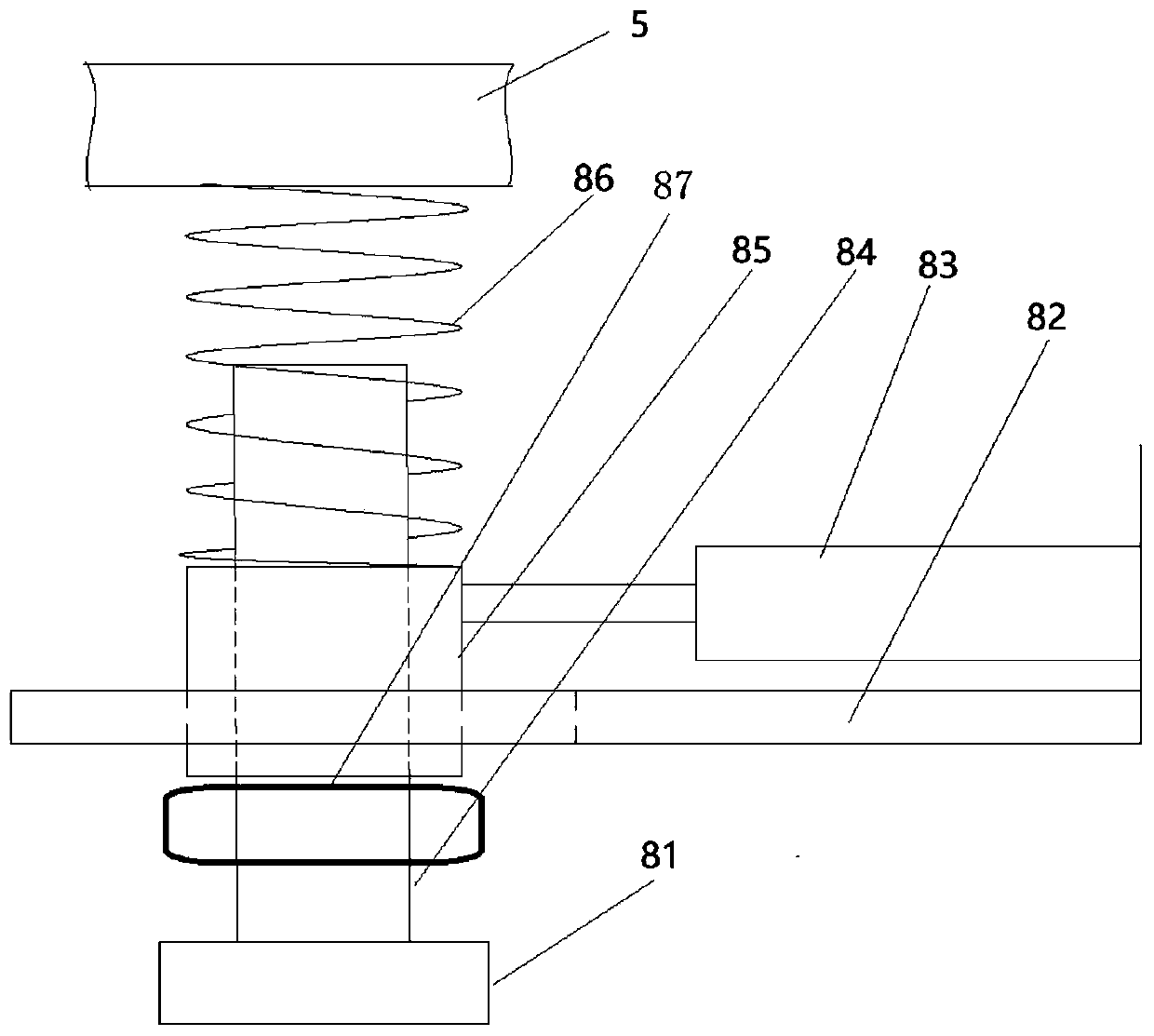

[0034] In this embodiment, the structure of the adjusting guiding device 8 is the same as that of the fixing guiding device. For example, the fixed guiding device includes a second fixed rod, a second bearing, and a second fixed plate; the second fixed rod includes a second cylinder and a second screw, and the second screw is screwed into an adapted first Two nuts. The size and connection relationship of each component are the same as those of the adjustment guide mechanism.

Embodiment 2

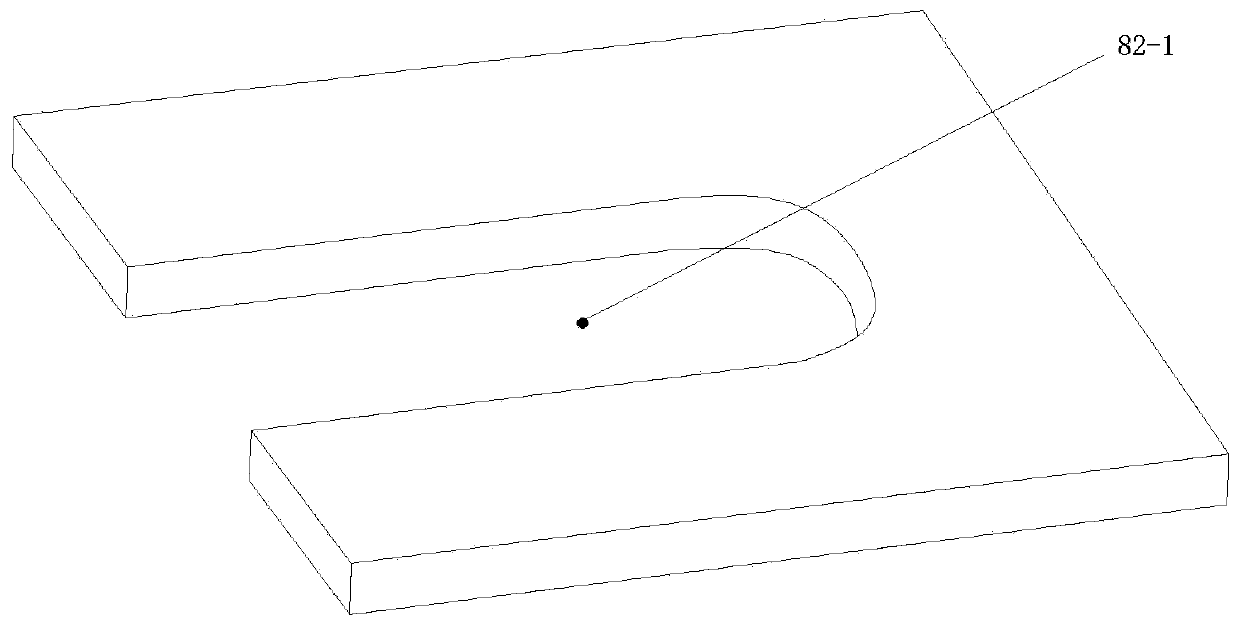

[0036] In Embodiment 1, since the structure of the adjustable guiding device 8 is the same as that of the fixed guiding device, neither of them can adjust the positional relationship during use to obtain a solution that is more beneficial to turning. Therefore, the width of the guide rail groove is generally larger than the diameter of the bearing 81 Only 20-30mm larger can meet the turning requirements of the trolley. If the distance between the bearing 81 and both sides of the guide rail groove is small, the turning angle of the trolley will be reduced; if the distance between the bearing 81 and both sides of the guide rail groove is large, the running process of the trolley will be unstable, and the bearing 81 will hit the inner side of the guide rail groove back and forth, which will intensify The whole car shakes, shaking the parts on the car. For this reason, this embodiment further improves the adjustment guide device 8 arranged at the rear end of the vehicle frame 5 . ...

Embodiment 3

[0040] As a further improvement to Embodiment 2, when using the bearing 81 as a guide for guiding, the bearing 81 must be in a horizontal state. If the fixed rod 89 or the screw rod 81 or other parts are hit, the bearing 81 is inclined upward or downward, causing the bearing 81 to be in a horizontal state. When contacting the side wall of the guide rail groove, upward or downward separation will occur, which not only affects the guiding ability of the bearing 81, but also affects the forward speed of the trolley. Therefore, design a kind of guide wheel of rolling ball type to replace bearing 81 as guide member. Specific reference Figure 4-5 , The guide wheel includes a base 14 , an iron ball 10 , and a limiting device, and the top surface of the base 14 is welded to the lower end of the screw rod 81 . The base 14 is a block body, and U-shaped grooves 15 are provided on its two opposite end faces, so that the base 14 is in the shape of an "I". Two ends of the base 14 are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com