Heating device for processing of bent tempered glass

A heating device and glass technology, applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve problems such as glass breakage, achieve the effects of improving safety, ensuring stability, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

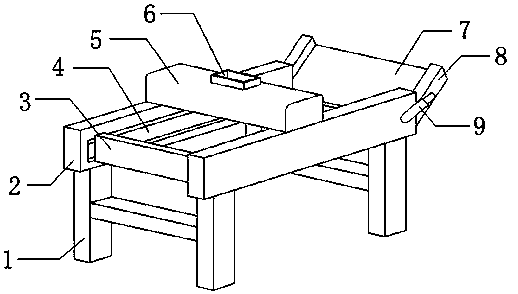

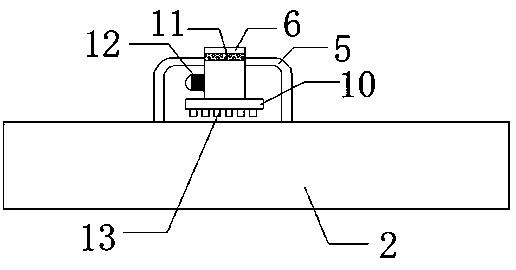

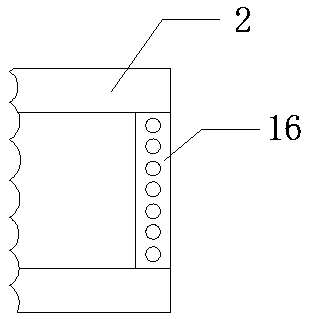

[0029] A heating device for processing bent tempered glass, such as Figure 1-4 As shown, it includes two first support plates 2 and four support legs 1, and the four support legs 1 are installed on the outer walls on both sides of the bottom of the two first support plates 2 respectively by bolts, and the tops of the two first support plates 2 The outer wall of one side is connected with the same supporting shell 5 by bolts, and the top central outer wall of the supporting shell 5 is connected with the air inlet pipe 6 by bolts, and the bottom outer wall of the air inlet pipe 6 is connected with the air distribution pipe 10 by bolts, and the air distribution pipe 10 is connected by bolts. The outer wall of the bottom of the pipe 10 is connected by bolts with spray nozzles 13 equidistantly arranged, the outer wall of the bottom of one side of the circumference of the air inlet pipe 6 is connected with a hot air blower 12 by bolts, and the outer walls of one side of the two firs...

Embodiment 2

[0034] A heating device for processing bent tempered glass, such as Figure 1-5As shown, it also includes a mounting groove opened on the outer wall of the other side of the adjacent one end of the two first support plates 2, and the inner walls of the two mounting grooves are connected with a first rotating rod 17 through a spring, and the first rotating rod 17 The outer wall on one side of the circumference is connected with a connecting plate 20 by bolts, and the outer walls at adjacent ends of the two connecting plates 20 are connected with a third rotating rod 21 through bearings, and the outer walls at adjacent ends of the two third rotating rods 21 are connected with a connecting rod through a bearing. The first roller 22 and the outer bottom wall at the other side adjacent to one end of the two first support plates 2 are connected with the second roller 23 through bearings.

[0035] In this embodiment, when the glass moves between the first roller 22 and the second rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com