A kind of preparation method of ganciclovir

A technology of ganciclovir and triacetyl, applied in the field of preparation of ganciclovir, can solve the problem that the quality of ganciclovir is low, the main purity can only reach 99.0%, the yield and quality of triacetyl ganciclovir products Low problems, to achieve the effect of no toxicity and danger, low production cost, and simplified operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

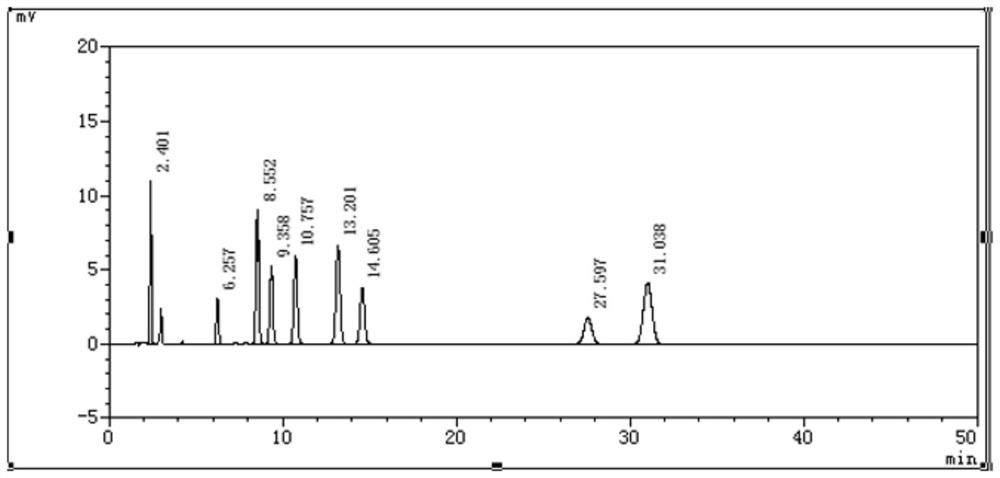

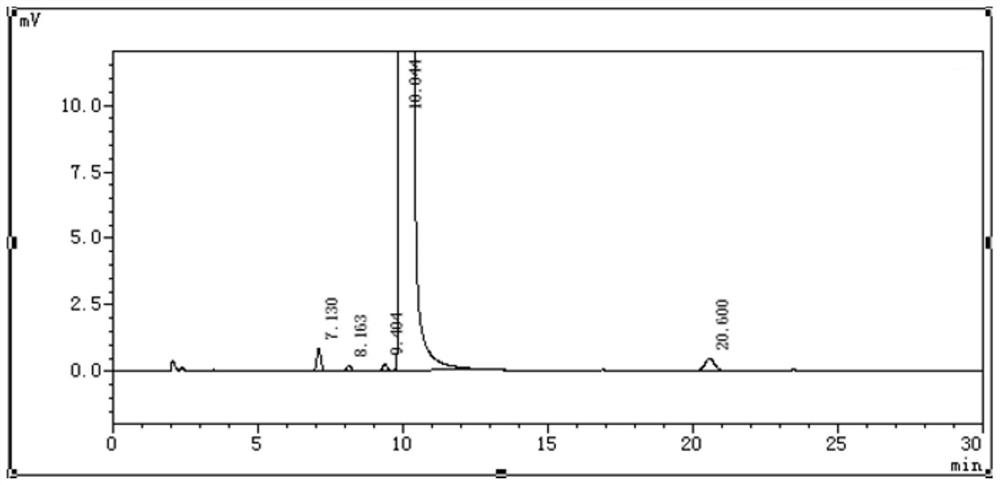

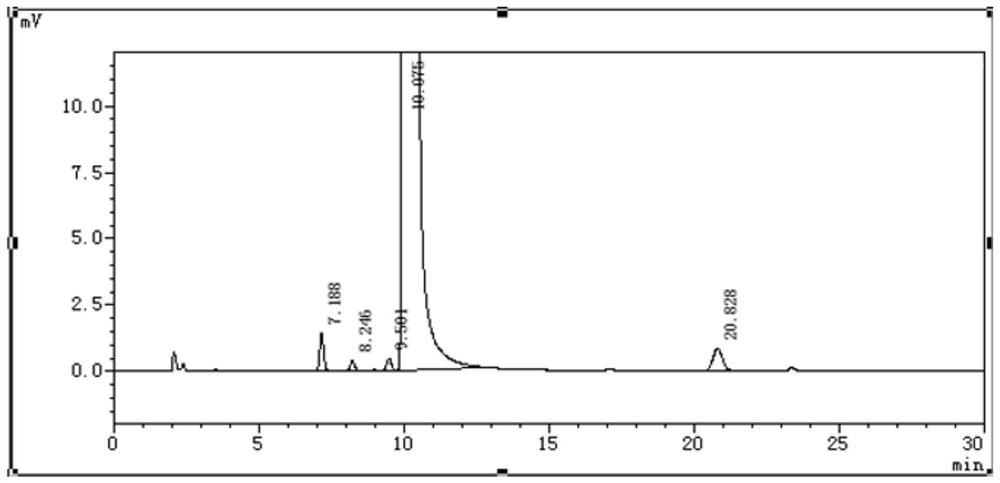

Image

Examples

Embodiment 1

[0025] Embodiment 1 of the present invention provides a kind of preparation method of ganciclovir, comprises the steps:

[0026] Step 1: Synthesis of Triacetylganciclovir

[0027] Put 30.0g of diacetylguanine, 120ml of dioxane, 61.0g of glyceryl acetal and 2.3ml of trifluoroacetic acid into a 500ml three-necked bottle, heat to 80°C in an oil bath under stirring, react for 50h, and track the reaction by TLC [developer : Chloroform: methyl alcohol=85: 15], cool to 20 ℃ after reaction finishes, filter, filter cake is washed with 20ml dioxane, add in methanol (50ml), be heated to 60 ℃, stir to make it dissolve, filter, The filtrate was cooled to 0°C and crystallized for 30 minutes, filtered, and the filter cake was dried at 60-80°C for 5 hours to obtain 14.0 g of light yellow crude product I of triacetylganciclovir. The filtrate was concentrated to dryness under reduced pressure, and the residue was added to 100ml of a mixed solvent of methanol: ethyl acetate = 1:4, heated to 60°...

Embodiment 2

[0039] Embodiment 4 of the present invention provides a kind of preparation method of ganciclovir, except that step 3 is changed to "the volume-to-weight ratio of the ethanol aqueous solution and the crude product of ganciclovir is 75:1; the unit of the volume-to-mass ratio Be ml / g; The weight of described gac is except the 2.5% of Ganciclovir crude product weight ", all the other are all the same as embodiment 1.

Embodiment 3

[0041] Embodiment 4 of the present invention provides a kind of preparation method of ganciclovir, except that step 3 is changed to "the volume-to-weight ratio of the ethanol aqueous solution and the crude product of ganciclovir is 85:1; the unit of the volume-to-mass ratio Be ml / g; The weight of described gac is except the 5% of Ganciclovir crude product weight ", all the other are all with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com