A prefabricated stair shock-absorbing structure

A prefabricated and staircase technology, applied in the direction of stairs, shockproof, building components, etc., can solve the problems of floor fatigue at the weld, impact of connectors, hidden safety hazards, etc., and achieve the effect of reducing fatigue wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

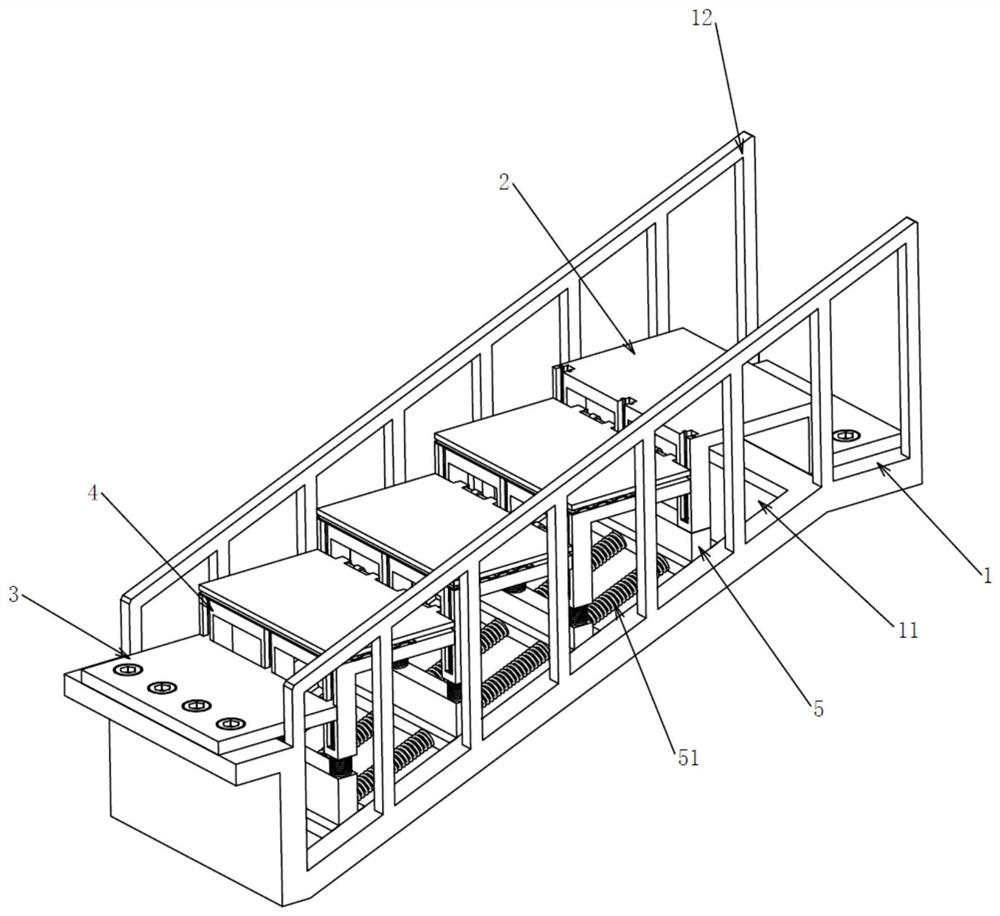

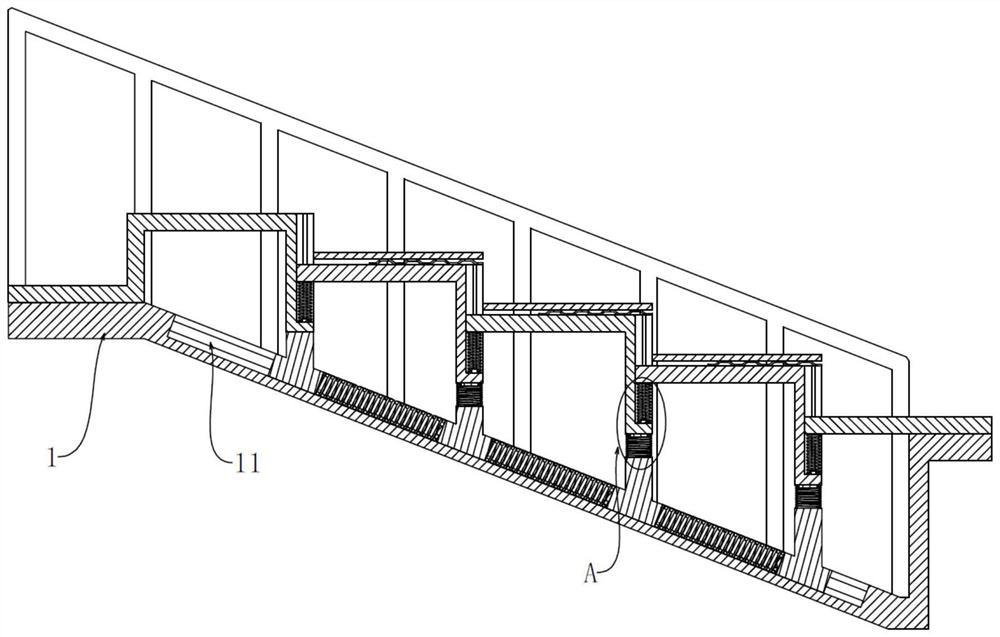

[0024] see Figure 1 to Figure 4 , the present invention provides a technical solution:

[0025] A prefabricated stair damping structure, including a base plate 1, a top stair plate 2, a bottom stair plate 3, a middle stair plate 4, a support seat 5 and a support spring I6, wherein:

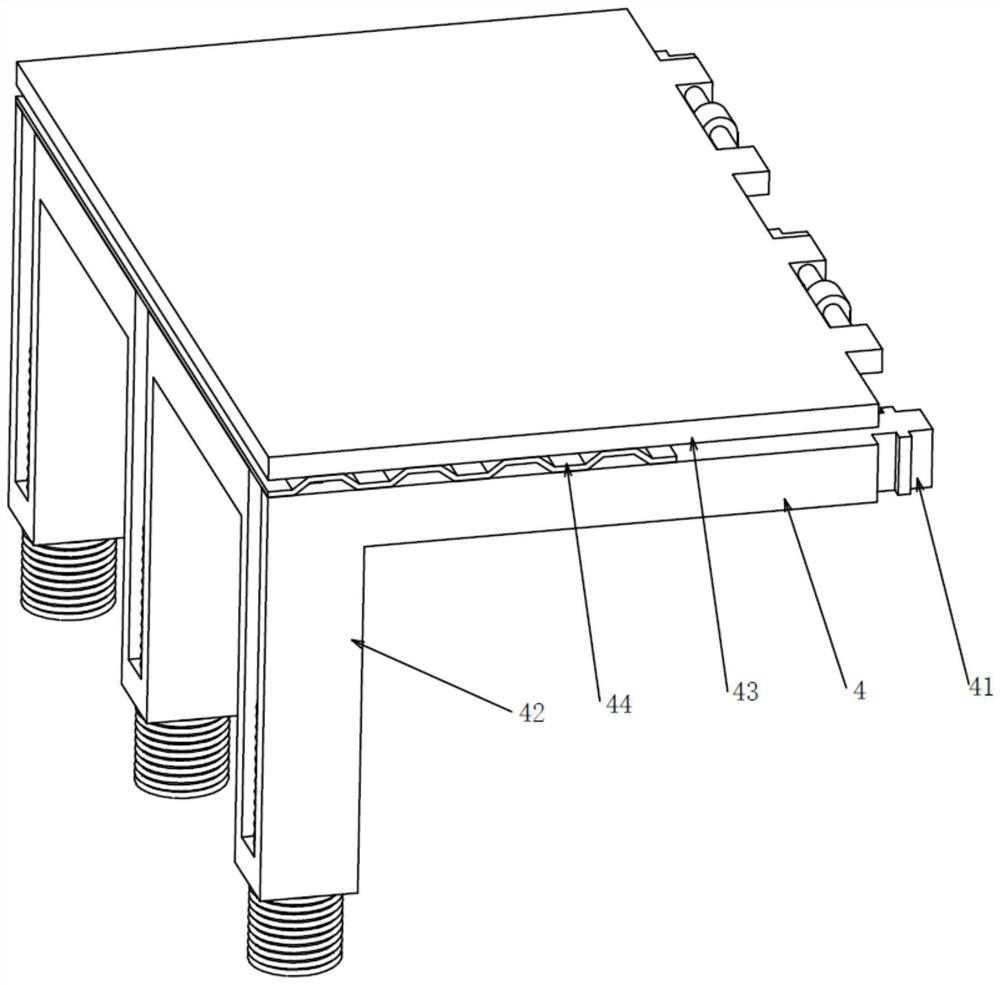

[0026] The inner bottom surface of the base plate 1 is provided with a guide groove 11 and handrails 12 are provided on both sides, the top stair plate 2 is installed on the top of the base plate 1 by bolts, and the bottom stair plate 3 is installed on the bottom of the base plate 1 by bolts, at least two middle stairs The boards 4 are alternately connected, wherein the side of the top stair board 2 is provided with a guide rail 42, the side of the bottom stair board 3 is provided with a guide block 41, and the two sides of the middle stair board 4 are respectively provided with a guide rail 42 and a guide block 41, alternately connected The guide blocks 41 in the middle stair boards 4 are match...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com