Five-dimensional direction adjustment system with gravity compensating mechanism

A direction adjustment and gravity compensation technology, which is applied in the direction of supporting machines, mechanical equipment, machine tables/supports, etc., can solve problems such as difficult adjustment or precise adjustment, complicated working process, and easy to be affected by gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

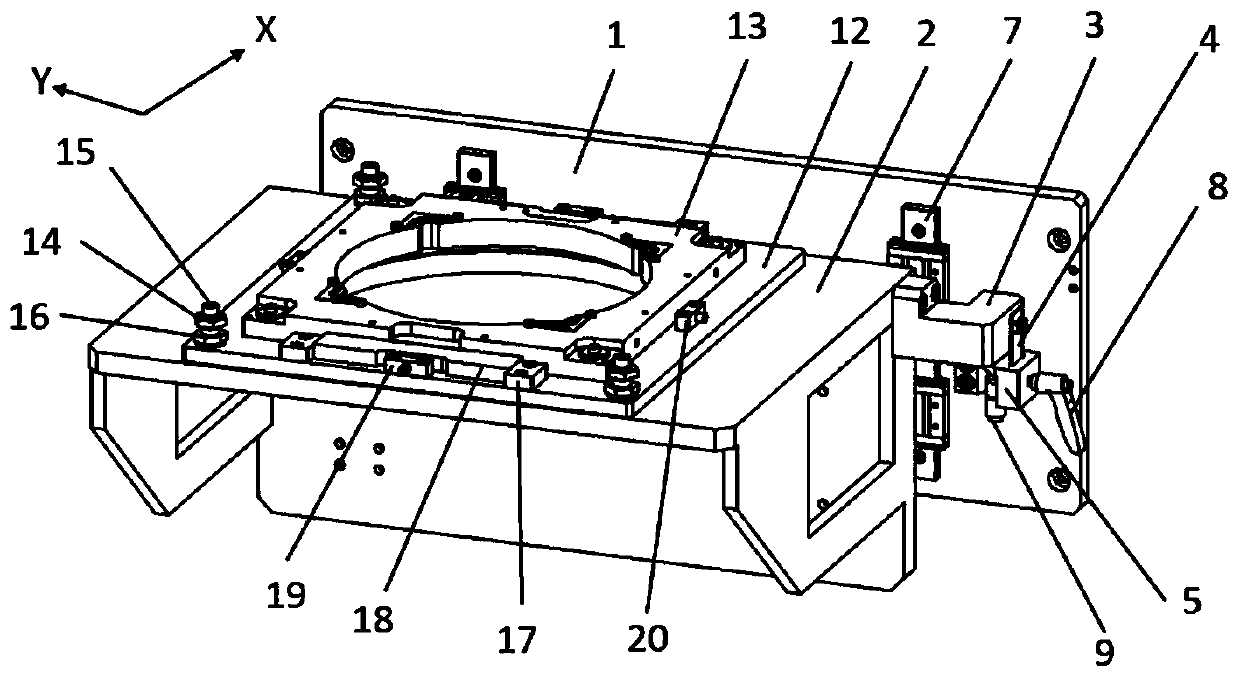

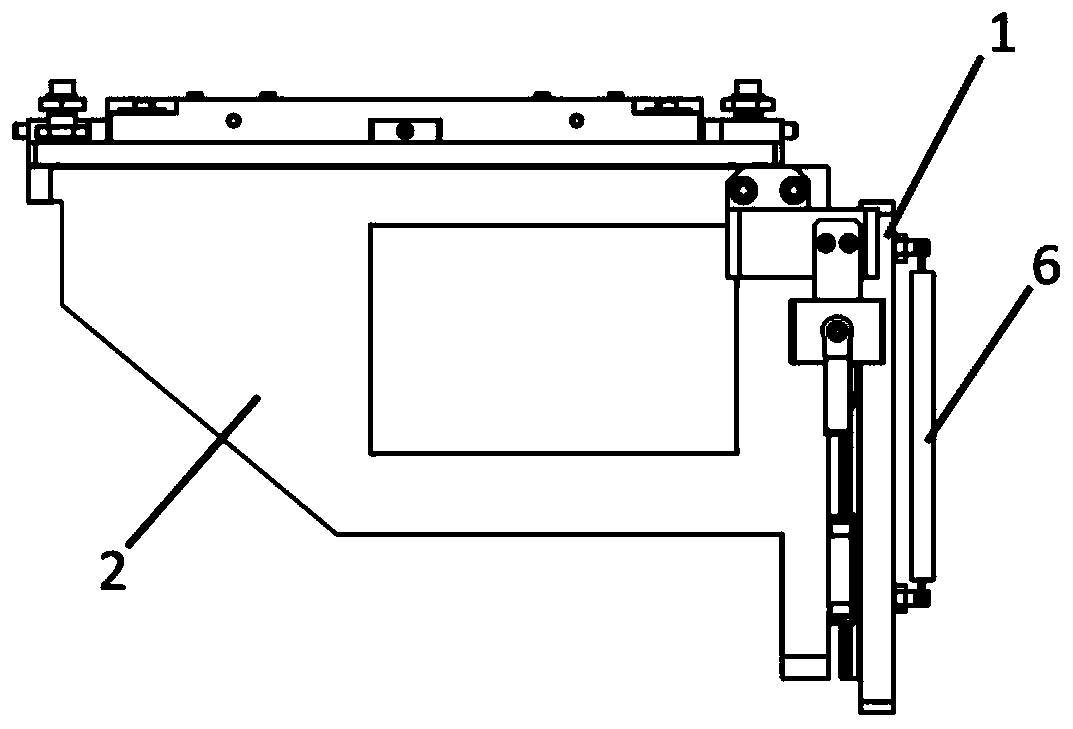

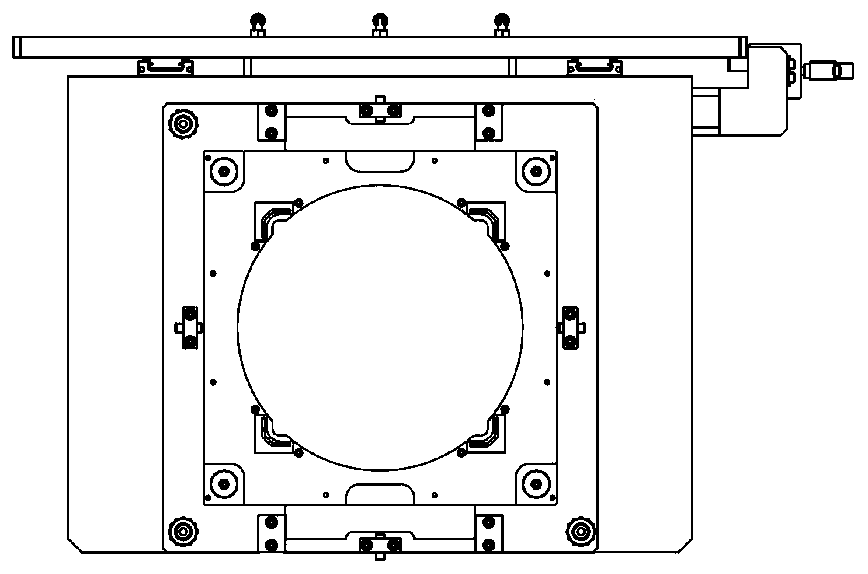

[0026] Such as Figure 1-6As shown, a five-dimensional direction adjustment system with a gravity compensation mechanism includes a backplane 1, a direction adjustment platform and a gravity compensation mechanism 6. The backplane 1 and the direction adjustment platform are arranged perpendicular to each other, and the backplane 1 is placed vertically. The adjustment platform includes base a2, base b 12 and base c 13 arranged in sequence from bottom to top. Base b 12 is fixed on base a 2 through the second height adjustment unit. The graphic board in the position can be adsorbed on the base plate c13 by a suction cup or fixed on the base plate c13 by other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com