Power signal detection equipment convenient to overhaul

A power signal, convenient maintenance technology, applied in the direction of electrical equipment structural parts, electrical equipment shell/cabinet/drawer, lighting and heating equipment, etc., can solve problems such as reducing the practical value of testing equipment, equipment damage, etc., to improve convenience , The effect of facilitating maintenance and reducing the time required for maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

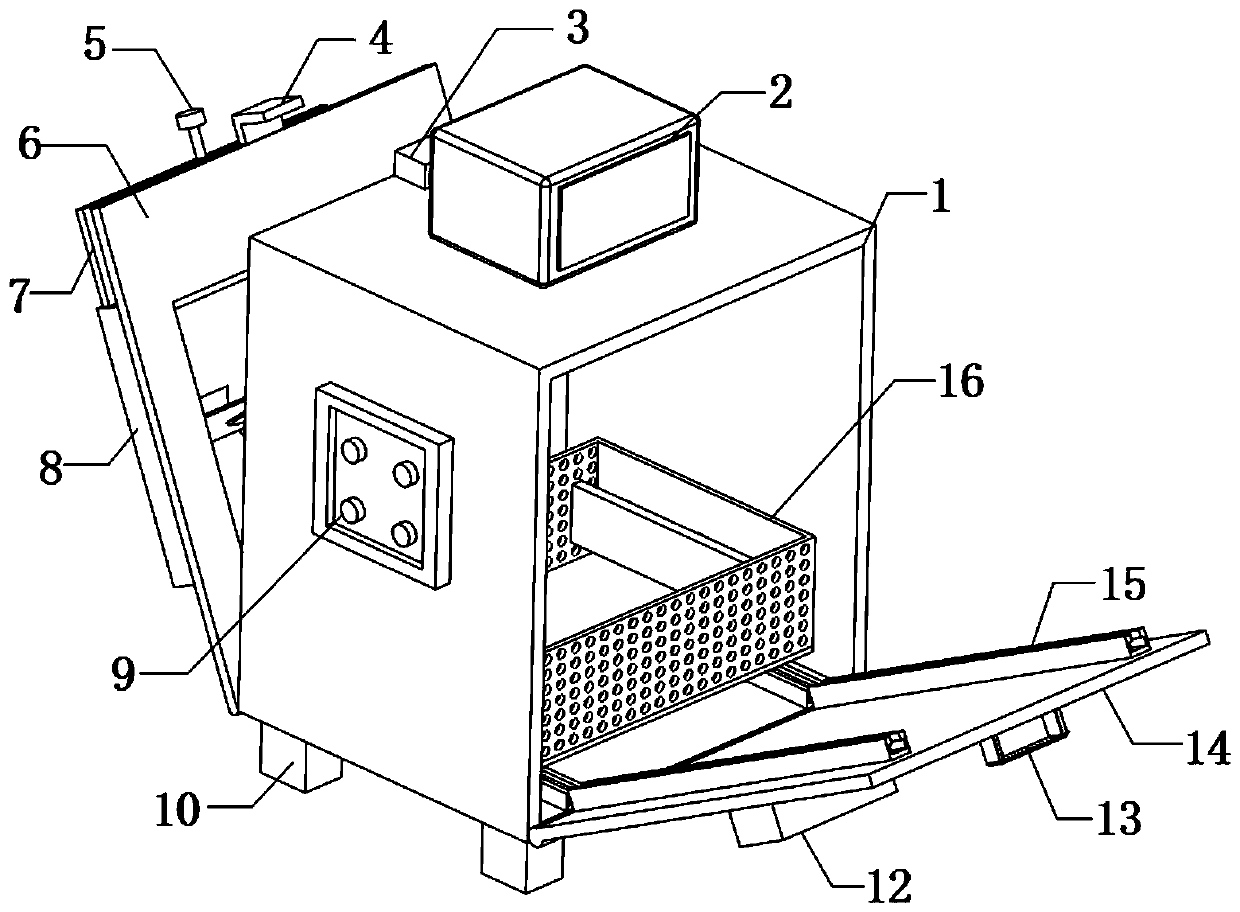

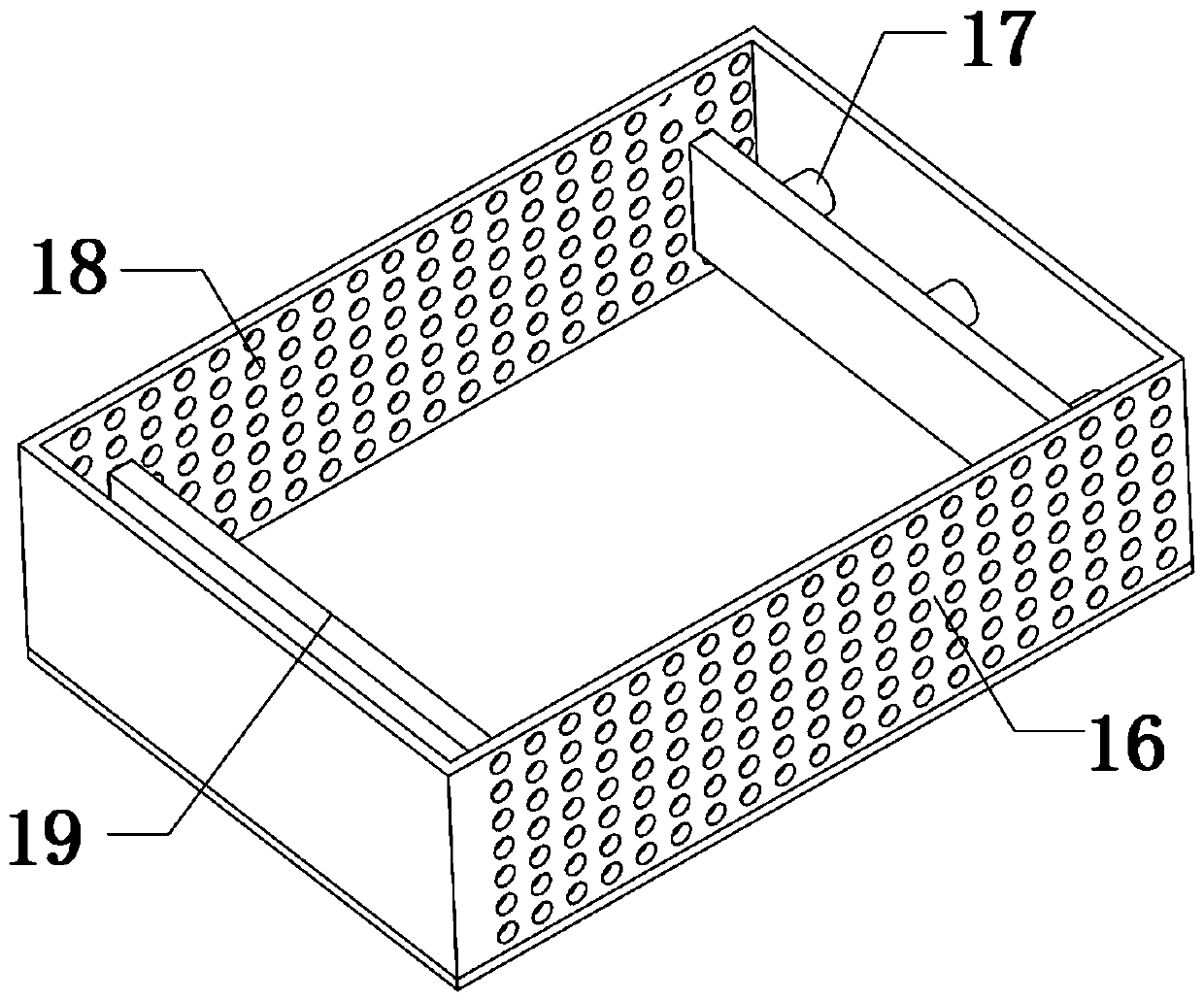

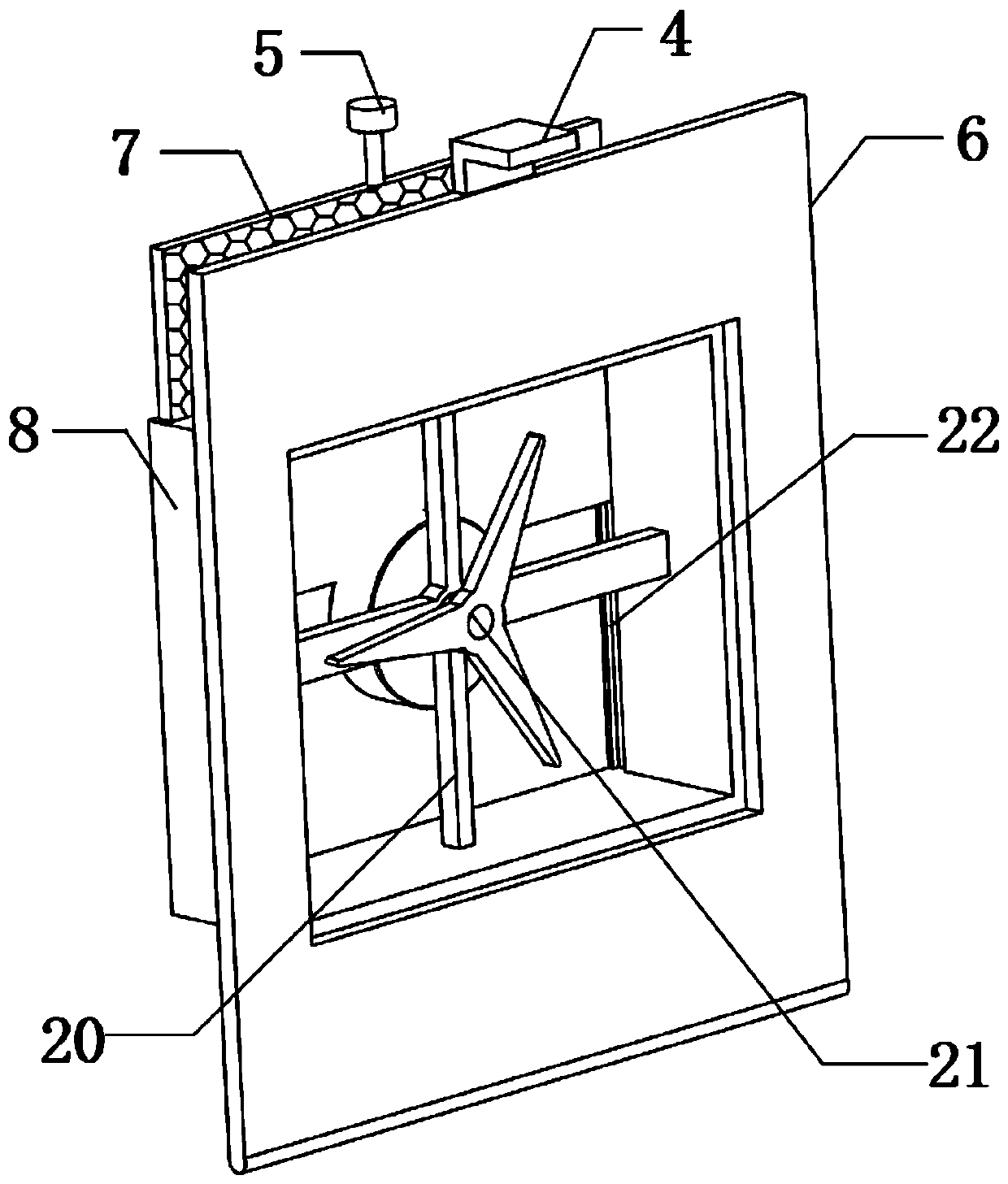

[0029] refer to Figure 1-4 , a power signal detection device for easy maintenance, including an installation box 1, both ends of the bottom inner wall of the installation box 1 are fixed with chute 25 by screws, and the inner walls of the two chute 25 are slidably connected with sliders 24, the two The top outer wall of each slider 24 is fixed with the same storage frame 16 by screws, and the inner walls on both sides of the storage frame 16 are fixed with two hydraulic rods 17 by screws, and the other ends of the two hydraulic rods 17 on one side are fixedly connected. There is the same fixed plate 19, four hydraulic rods 17 are connected with a synchronous hydraulic system, and the outer walls of both sides of the storage frame 16 are provided with cooling holes 18 at equal distances, through which a chute 25 and a slider 24 are provided, and the storage frame 16 passes through the slider. 24 is slidably connected to the inner wall of the chute 25. When installing the testi...

Embodiment 2

[0040] refer to Figure 2-6, a power signal detection device for easy maintenance, including an installation box 1, both ends of the bottom inner wall of the installation box 1 are fixed with chute 25 by screws, and the inner walls of the two chute 25 are slidably connected with sliders 24, the two The top outer wall of each slider 24 is fixed with the same storage frame 16 by screws, and the inner walls on both sides of the storage frame 16 are fixed with two hydraulic rods 17 by screws, and the other ends of the two hydraulic rods 17 on one side are fixedly connected. There is the same fixed plate 19, four hydraulic rods 17 are connected with a synchronous hydraulic system, and the outer walls of both sides of the storage frame 16 are provided with cooling holes 18 at equal distances, through which a chute 25 and a slider 24 are provided, and the storage frame 16 passes through the slider. 24 is slidably connected to the inner wall of the chute 25. When installing the testin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com