Closed zipper tooth and closed shielding zipper

A closed and chain element technology, which is applied in the field of zippers, can solve the problems that the chain elements do not have waterproof function, cannot achieve complete airtightness, poor waterproof effect, etc., and achieve the effect of improving strength, improving production efficiency, and increasing binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

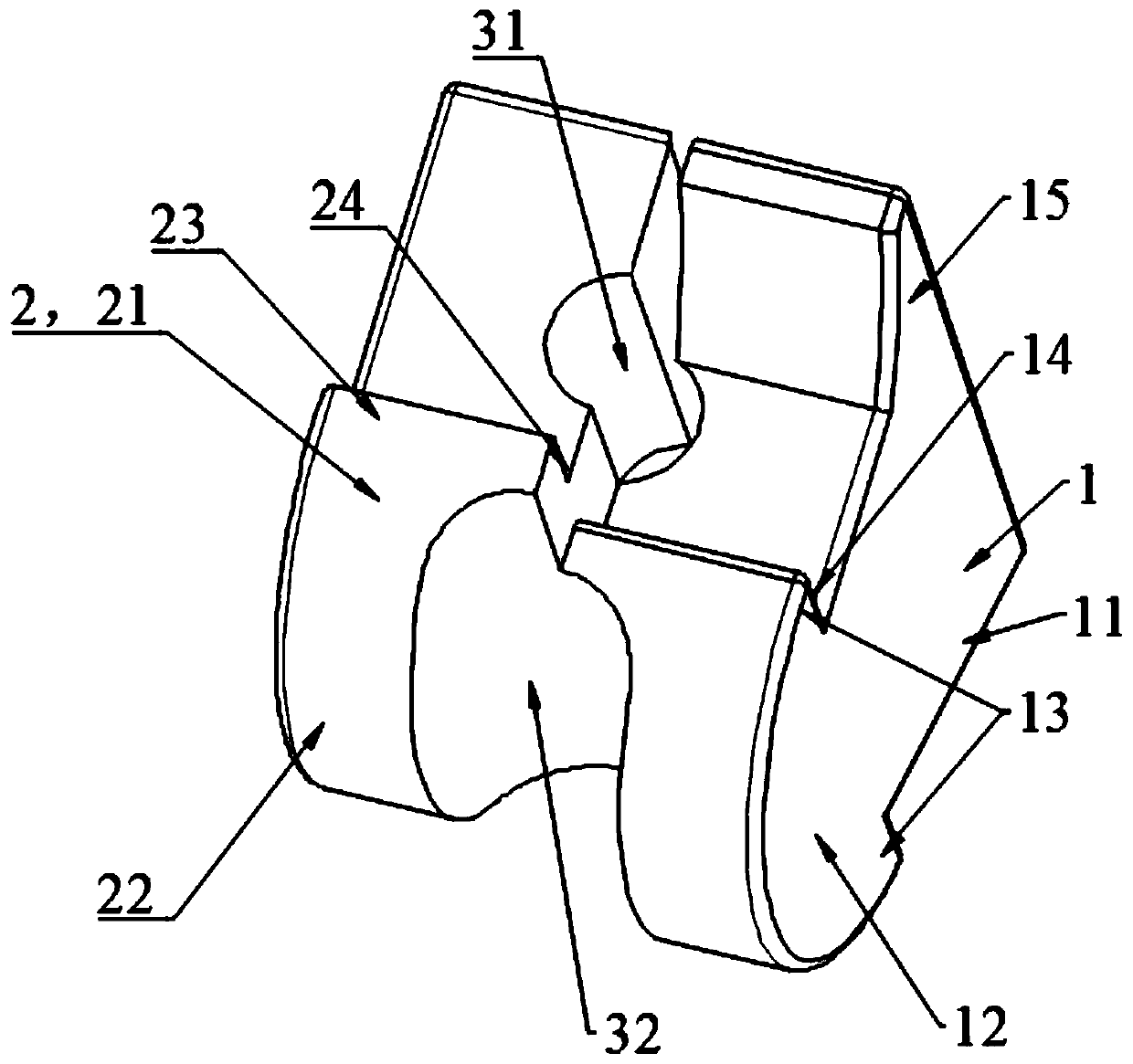

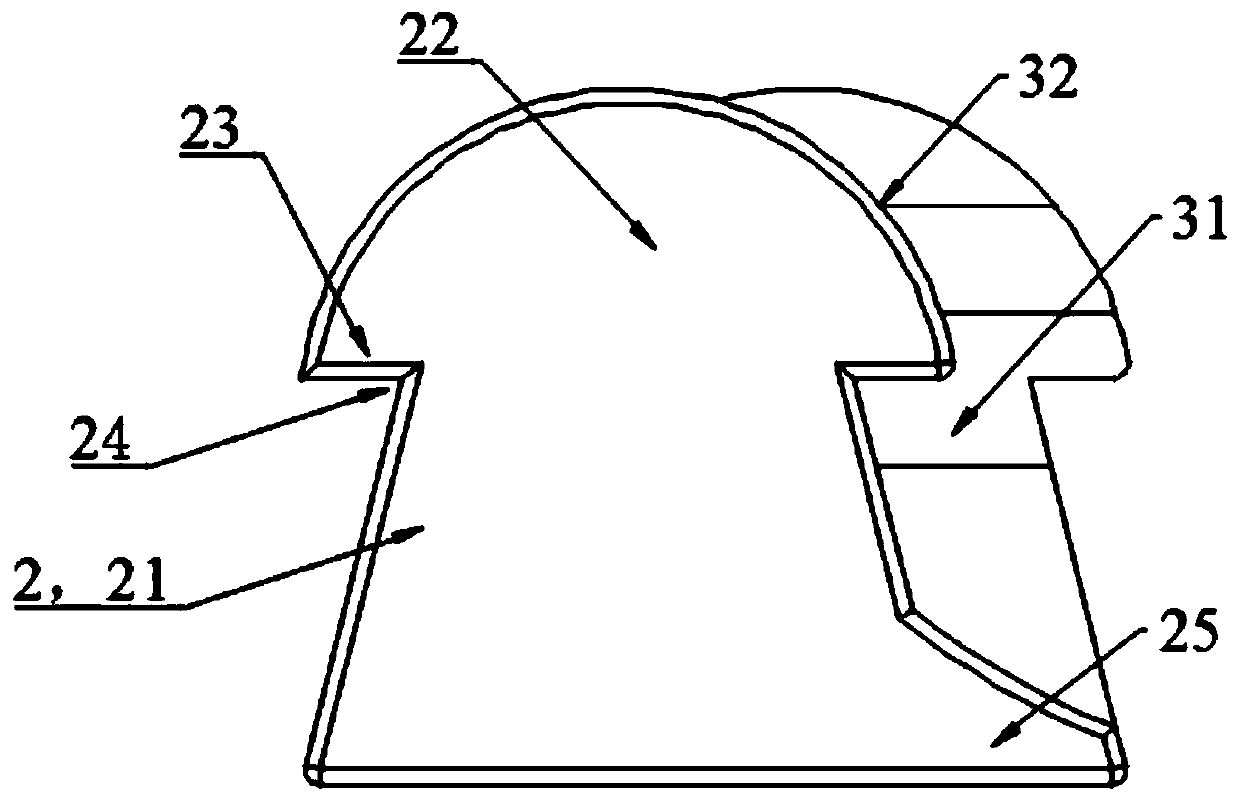

[0033] A closed fastener element, comprising a first thread 1, a second thread 2 and a cloth seam 31, the first thread 1 and the second thread 2 are misplaced; wherein,

[0034]The first teeth 1 includes a first teeth body 11, a first teeth engagement head 12, and a first teeth engagement groove 13, and the first teeth engagement head 12 is arranged on the first teeth body 11 towards the width direction. On both sides, the first teeth engaging convex part 13 is formed; the concave part between the first teeth engaging head 12 and the first teeth body 11 is the first teeth engaging groove 14, and the first teeth engaging head 12 forms an arc-shaped structure with the first teeth meshing protrusion 13, and the first teeth teeth body 11 is also provided with a first wedge-shaped tail 15 near the cloth seam 31;

[0035] The second tooth 2 comprises a second tooth body 21, a second tooth engagement head 22, and a second tooth engagement groove 23, and the second tooth engagement he...

Embodiment 2

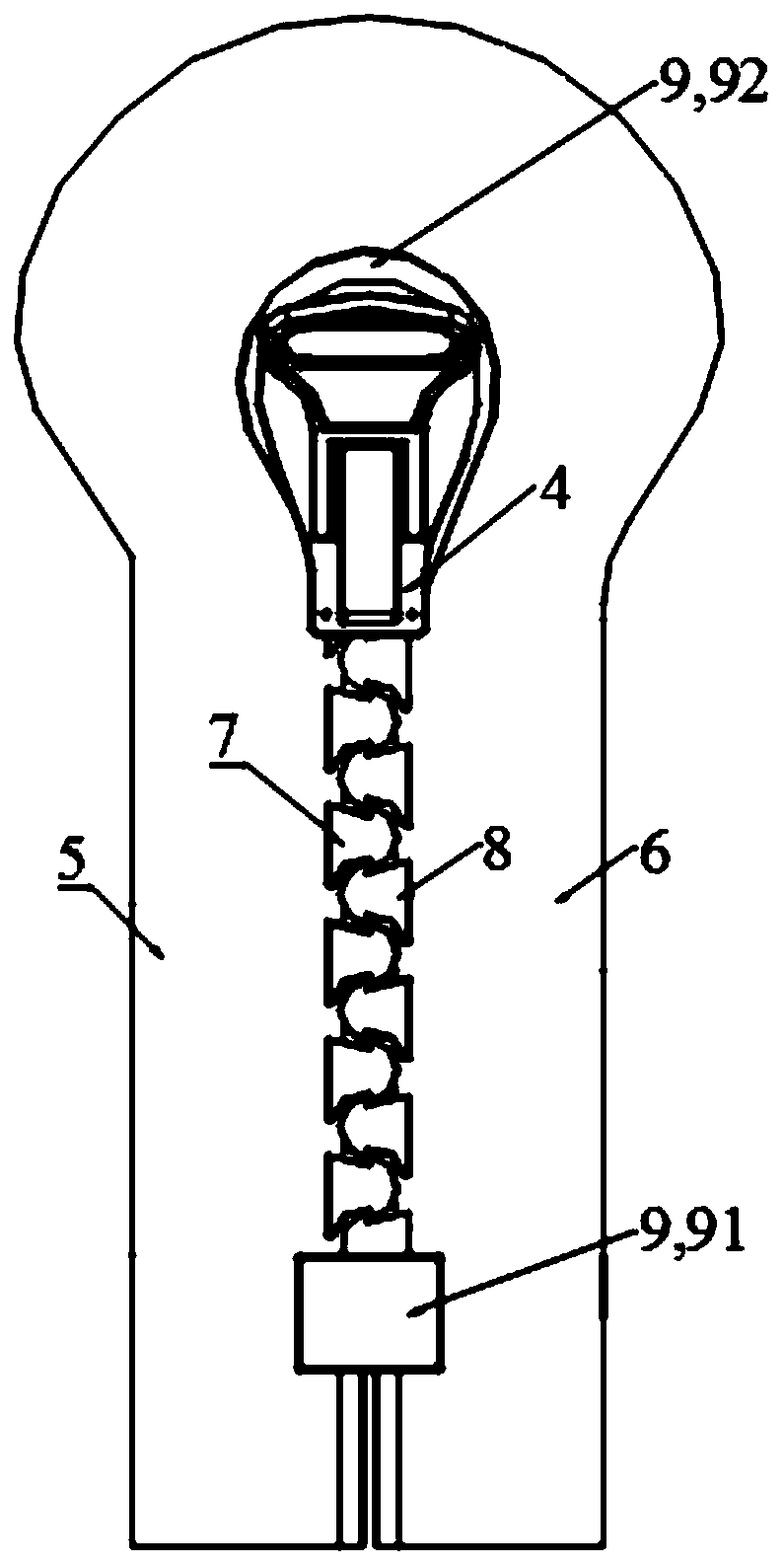

[0038] A closed shielding zipper, including a slider 4, a left cloth tape 5, a right cloth tape 6, a left chain element 7, a right chain element 8, and a locking member 9; the left chain element 7 and the right chain element 8 are Example 1 For the closed chain element, the left chain tooth 7 is clamped on the left cloth belt 5, and the right chain tooth 8 is clamped on the right cloth belt 6; the left chain tooth 7 and the right chain tooth 8 have the same shape; The setting positions of the fastener element 7 and the right fastener element 8 are dislocation and fixed connection of seamless meshing with each other, the left fastener element engaging protrusion 73 of the left fastener element 7 and the right fastener element engaging groove 84 of the right fastener element 8 engage with each other, and the The right chain element engagement protrusion 83 of the right chain element 8 engages with the left chain element engagement groove 74 of the left chain element 7;

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com