Emulsion spraying device for cold rolling unit and spraying pipeline design method of emulsion spraying device

A spray device and pipeline design technology, which is applied in workpiece lubrication devices, metal rolling, metal rolling, etc., can solve the waste of emulsion at the edge, defects in the shape and surface quality of secondary cold-rolled products, and cannot be precisely controlled Strip steel and other problems to achieve the effect of improving the lubrication performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

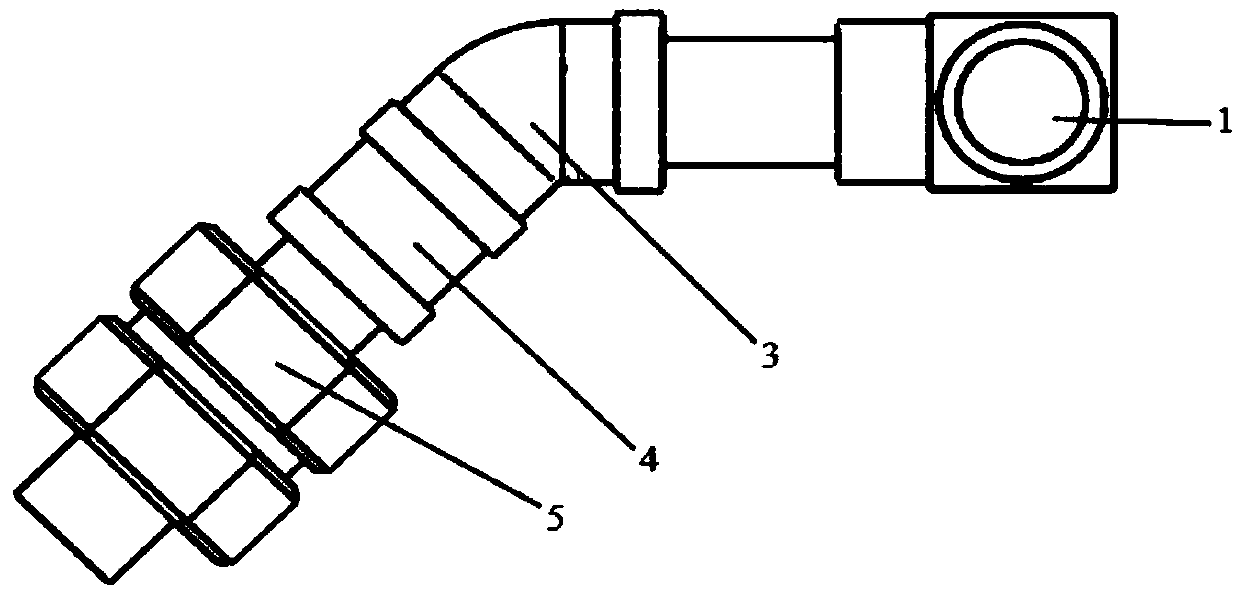

[0062] (1) Pipeline length selection, such as Figure 5 As shown, the specific process of pipeline length selection is as follows:

[0063] (a) Collect and calculate the required rolling lubrication process parameters, including: collect the equipment process parameters required for the design of spliced spray racks, including: nozzle spray height H = 150mm, nozzle spray direction angle α = 68°, nozzle spray angle θ = 50°.

[0064] (b) The maximum value S of the nozzle superposition area length max =50mm and minimum value S min =30mm, given the initial value of pipeline length L 0 =90mm and optimized step size ΔL=2mm. given l 1 = 10mm, l 2 = 40mm.

[0065] (c) Define the pipeline length search parameter i, and initialize i=1, the result record process parameter k, and initialize k=1, define the pipeline length L that meets the rolling lubrication requirements i , and its group number N, and initialize N=0.

[0066] (d) Calculate the spray width of a single nozzle: ...

Embodiment 2

[0088] (1) Pipeline length selection, such as Figure 5 :

[0089](a) Collect and calculate the required rolling lubrication process parameters, including: collect the equipment process parameters required for the design of spliced spray racks, including: nozzle spray height H = 200mm, nozzle spray direction angle α = 72°, nozzle spray angle θ = 58°.

[0090] (b) The maximum value S of the nozzle superposition area length max = 60mm and minimum S min =30mm, given the initial value of pipeline length L 0 = 150mm and optimized step size ΔL = 5mm. given l 1 = 15mm, l 2 = 60mm.

[0091] (c) Define the pipeline length search parameter i and initialize i=1, the result record process parameter k and initialize k=1, define the parameter L that satisfies the requirement of the length of the superposition area i and its group number N and initialize N=0.

[0092] (d) Calculate the spray width of a single nozzle:

[0093] (e) Calculate the pipeline length L i =L 0 +(i-1)Δ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com