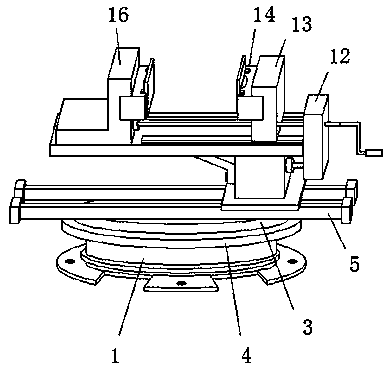

Bench work clamp device with automatic correction function for mold part machining

An automatic calibration and fixture device technology, applied in the field of fitters, can solve the problems of no automatic calibration of the position of the clamped object, inability to control the rotation speed well, and inconvenient operation for changing clamping molds, so as to improve convenience and application. Scope, time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

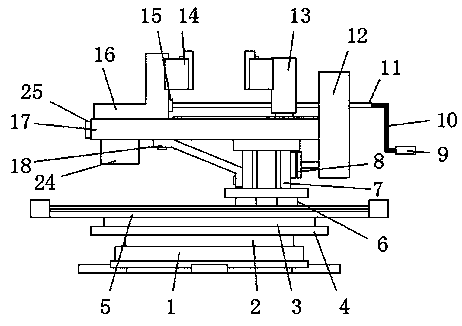

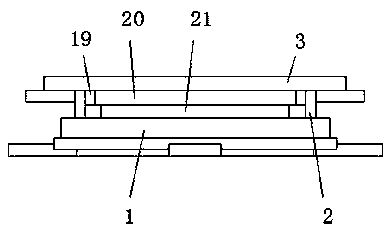

[0034] Example 1, such as Figure 5 , 6 : the motor 8 is controlled by the control panel 25, the output end of the motor 8 drives the first rotating rod 1206 to rotate, thereby driving the first gear 1201 to rotate, yes the first gear 1201 drives the second gear 1203 to rotate, and the second gear 1203 can rotate the The rotating speed is reduced by ten times, and the second gear 1203 drives the second rotating rod 1202 to rotate, thereby driving the third gear 1204 to rotate, and the third gear 1204 drives the fourth gear 1205 to rotate, and simultaneously the fourth gear 1205 reduces the rotating speed by ten times again. The four gears 1205 drive the screw rod 11 to rotate, through the screw thread between the screw rod 11 and the mobile table 13, the rotational torque is converted into the force that drives the mobile table 13 to move horizontally, so that the mobile table 13 moves, and the clamping structure 14 will be positioned at the mobile The mold between the table ...

Embodiment 2

[0035] Example 2, such as Figure 7 , 8 : The clamping structure 14 can be adjusted according to the shape of the mould. When the shape is a regular shape, it can be clamped directly through the splint 1404. When some arc-shaped molds need to be clamped, the splicing block 1403 and the splicing groove 1402 can be clamped. Separate, so that the splint 1404 is removed, and the arc-shaped mold is clamped through the arc-shaped groove 1405. When clamping some square molds, the clamping block 1406 can be pulled out from the inside of the square groove 23, and then the square mold is clamped. Set inside the square groove 23.

[0036] Working principle: Charge the battery before use, and the battery supplies power to the device during use. First, fix the base 1 at the designated position through the ear socket, and then fix the fitter fixture at the designated position. When the mold needs to be clamped, the mold can be placed Between the fixed platform 16 and the mobile platform 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com