Parts supply process control method and system

A technology of process control and parts, applied in the field of logistics, can solve problems such as error-prone and time-consuming manual checks, and achieve the effects of preventing picking errors, improving delivery accuracy and operating efficiency, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

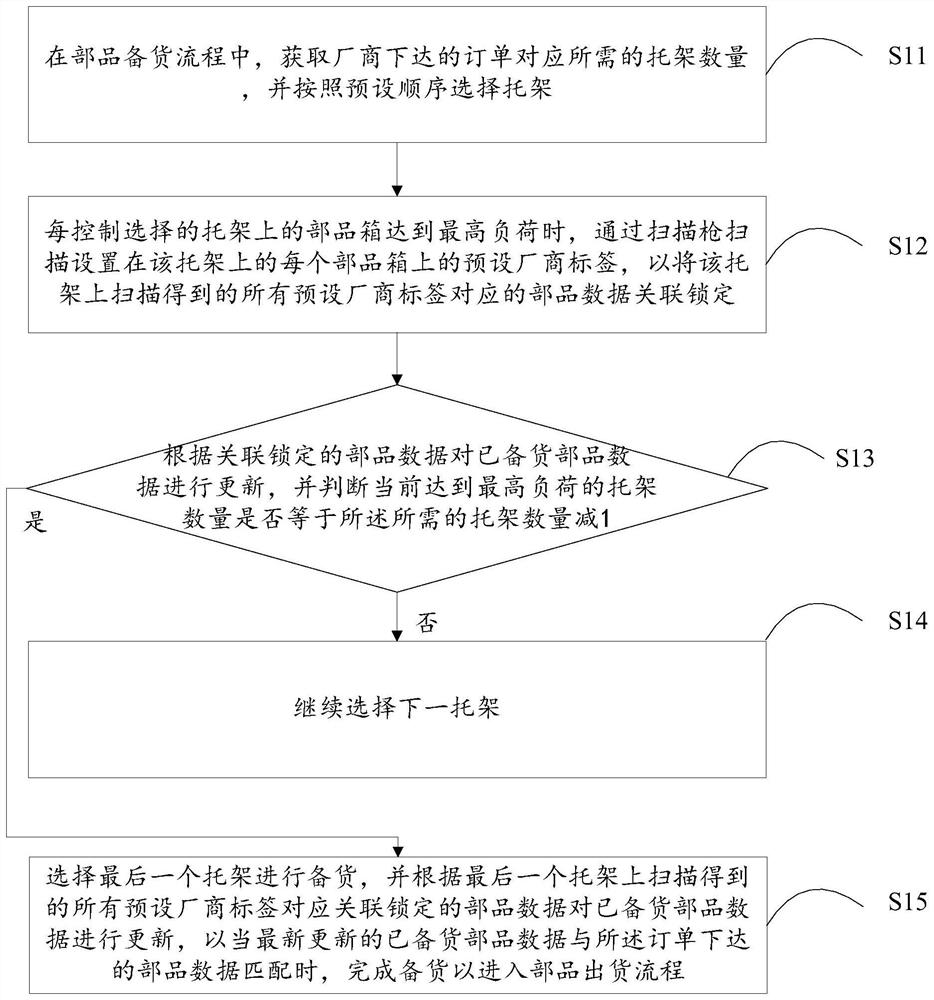

[0049] see figure 1 , in an embodiment of the method for controlling the parts supply process of the present invention, the method includes the steps of:

[0050] Step S11, in the parts stocking process, obtain the number of brackets required for the order placed by the manufacturer, and select the brackets according to the preset order;

[0051] Step S12, when the part box on the selected bracket reaches the highest load, scan the preset manufacturer label on each part box set on the bracket through the scanning gun, so as to scan all the parts obtained on the bracket. The part data corresponding to the default manufacturer label is locked;

[0052]Step S13, update the stocked parts data according to the associated locked parts data, and judge whether the current number of brackets with the highest load is equal to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com