A uniform material distribution control method for reciprocating feeding and distributing cranes

A technology of uniform distribution and control method, which is applied in the conveyor control device, loading/unloading, conveyor and other directions, can solve the problem of inconsistent speed of materials relative to the discharge port, etc., to maintain stability, improve uniformity, and achieve obvious effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

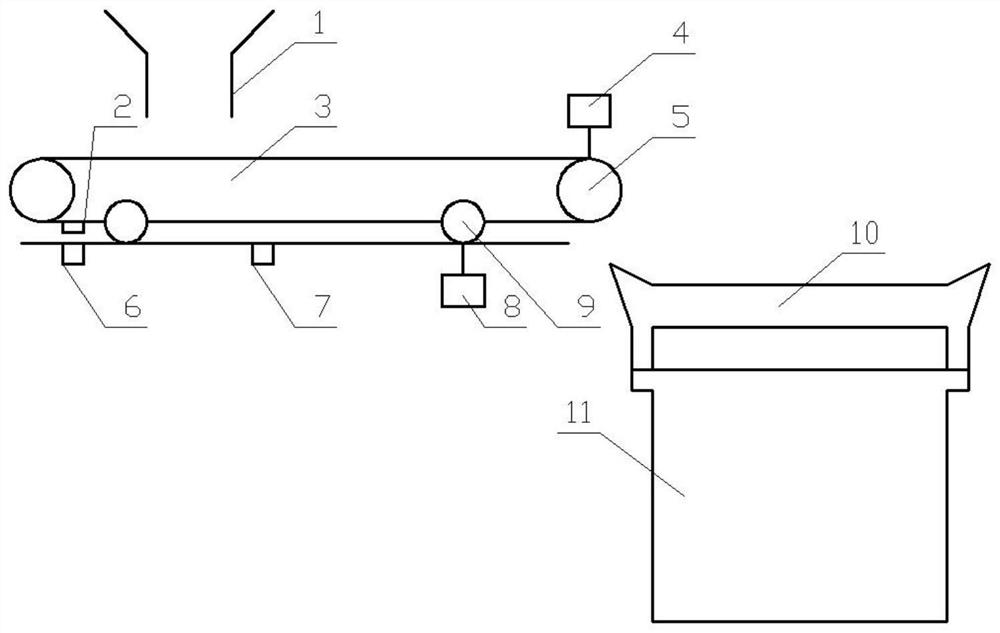

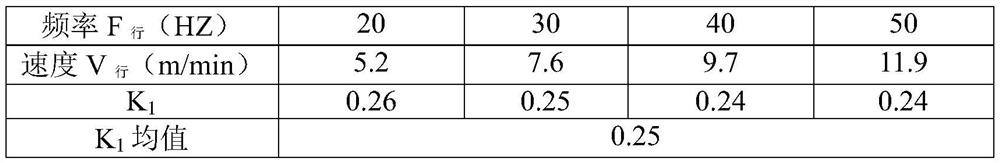

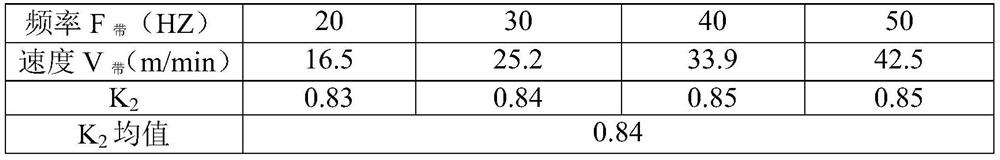

[0020] Such as figure 1 As shown, a method for uniform material distribution control of a reciprocating feed distribution crane, the device carrying the method includes a belt motor 5 and a travel motor 9 on the distribution crane 3, and the feeding mechanism of the feeder 11 is mainly composed of the distribution crane 3 and The laying crane 10 is composed of material passing through the upper conveyor belt from the discharge port 1 to the distribution crane 3, the belt motor 5 controls the speed through the belt frequency converter 4, the belt runs in a single direction to the material spreading crane 10, and the travel motor 9 passes through the travel frequency converter 8 control speed, carry out reciprocating operation on the top of the laying vehicle 10, the induction sheet 2 is arranged under the distribution vehicle 3 and the operatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com