A kind of high and low temperature resistant sealant and its preparation method and application

A high and low temperature resistant sealant technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem that sealants cannot meet market requirements, degumming, and cannot meet high and low temperature performance at the same time Questions such as requirements

Active Publication Date: 2021-06-18

湖南伟一新材料有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Most of the sealant products currently on the market cannot meet the performance requirements of high and low temperature at the same time, and the problem of degumming occurs in an environment with a wide range of temperature changes. Therefore, the current sealant cannot meet the requirements of the market. Therefore, it is urgent to develop a High and low temperature resistant sealant

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

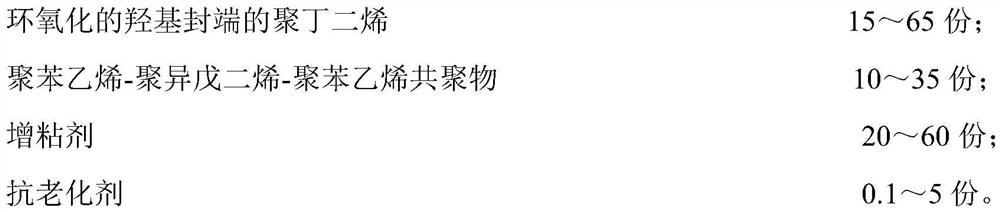

Embodiment 1

[0026]

[0027]

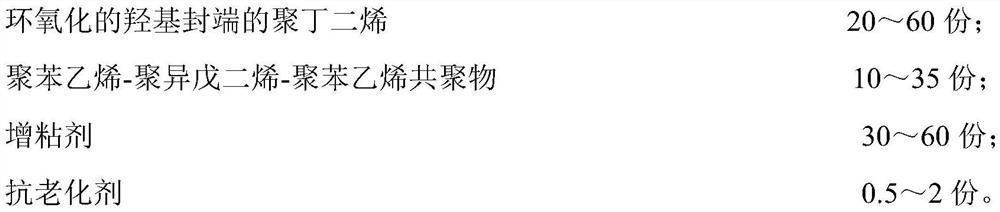

Embodiment 2

[0029]

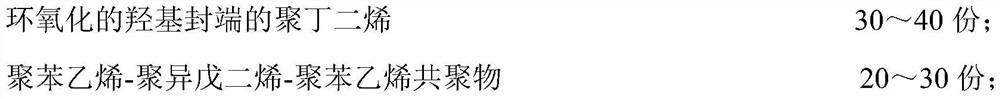

Embodiment 3

[0031]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a high and low temperature resistant sealant and its preparation method and application. The sealant comprises the following raw materials: epoxidized hydroxyl-terminated polybutadiene, polystyrene-polyisoprene-polystyrene Copolymer, tackifier and anti-aging agent. The sealant of the present invention can still maintain excellent viscosity in the temperature range of -30 to 80°C, and the 180° peeling force for PE materials is ≥ 22N / 25mm, and the 90° peeling force is ≥ 30N / 25mm; for EPDM materials 180° peeling force ≥ 9N / 25mm, 90° peeling force ≥ 16N / 25mm; 180° peeling force ≥ 35N / 25mm, 90° peeling force ≥ 28N / 25mm for painted doors, there will be no degumming phenomenon . The sealant of the invention is especially suitable for PE materials, EPDM materials, painted doors and plastic doors.

Description

technical field [0001] The invention relates to the field of glue, in particular to a high and low temperature resistant sealant and its preparation method and application. Background technique [0002] Sealant refers to a sealing material that is deformed due to the shape of the sealing surface, is not easy to flow, and has a certain degree of adhesion. According to different vulcanization methods, it can be divided into wet air vulcanization type sealant and chemical vulcanization type sealant; according to different forms, it can be divided into paste sealant, liquid elastomer sealant, hot melt sealant; according to the performance after construction, it can be divided into It is divided into curing type sealant and non-curing type sealant. The application range of sealant is very wide, and it can bond leather, glass, metal, doors and windows, plastics, textiles, etc. [0003] Most of the sealant products currently on the market cannot meet the performance requirements o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09J193/04C09J147/00C09J153/02C09J11/06C09J11/08

CPCC08L2201/08C08L2205/03C09J11/06C09J11/08C09J147/00C09J193/04C08L47/00C08L53/02C08K5/13C08L93/04

Inventor 吴国文龙旭李华

Owner 湖南伟一新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com