Method for determining design parameters of spring return type seat

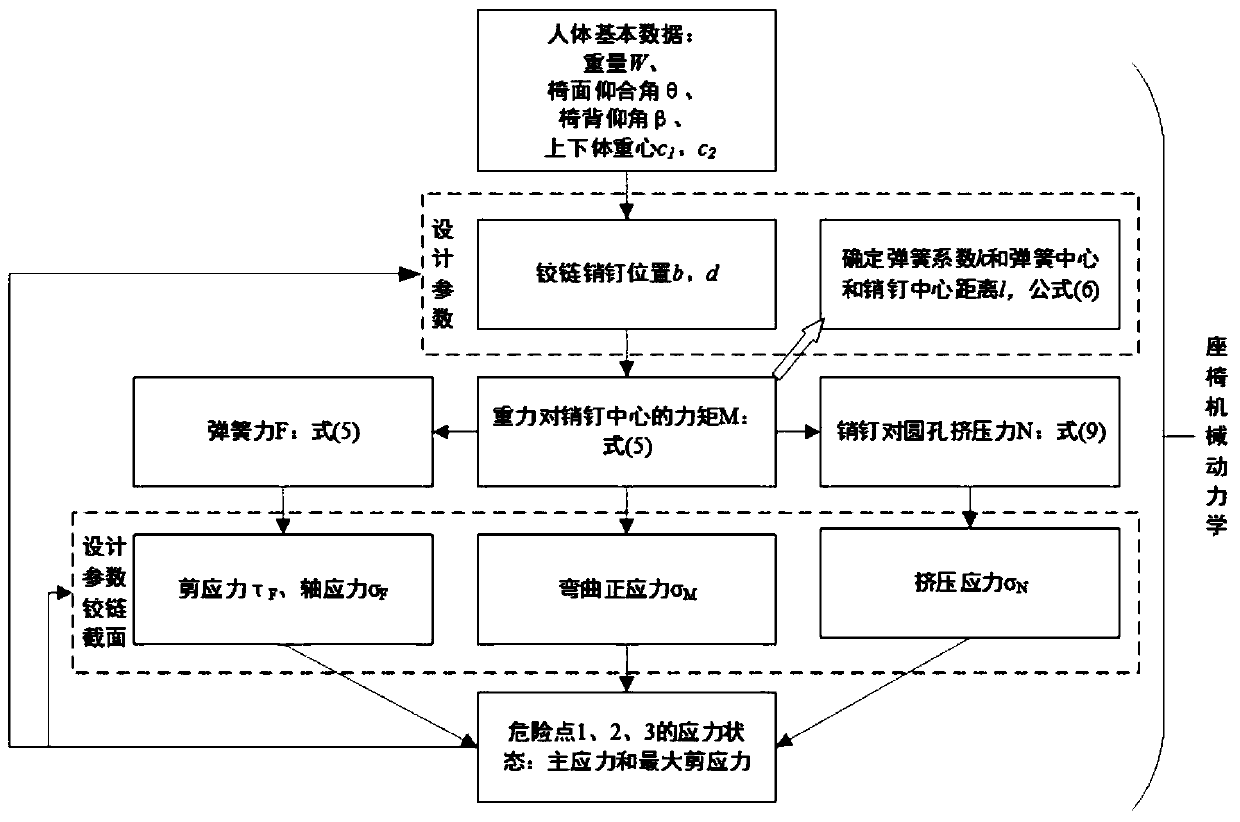

A technology for designing parameters and determining methods, applied in electrical digital data processing, instruments, geometric CAD, etc., to achieve the effect of simple calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be described in further detail below in conjunction with the accompanying drawings.

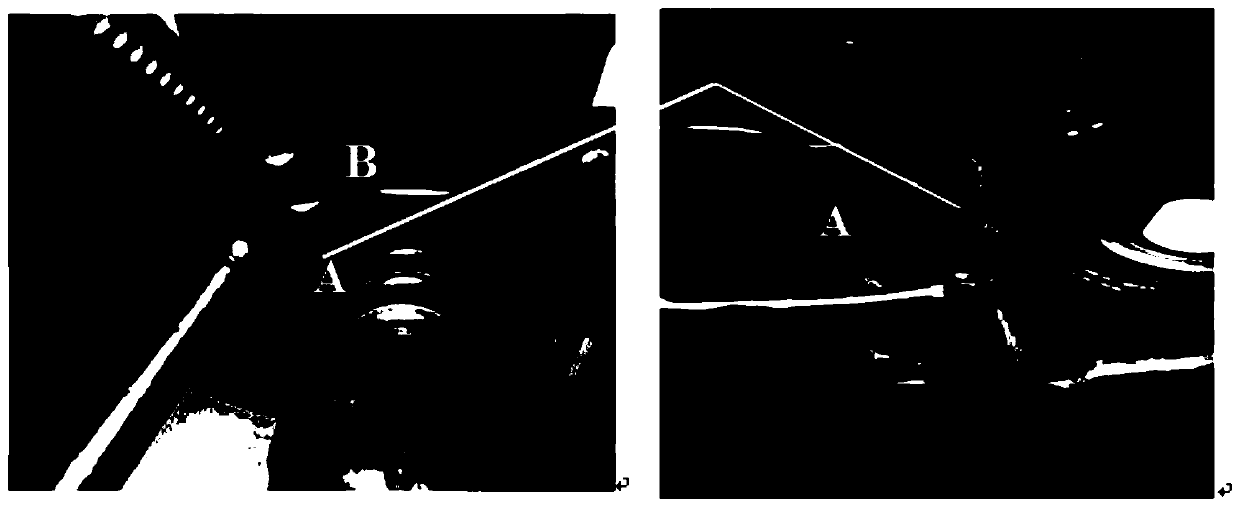

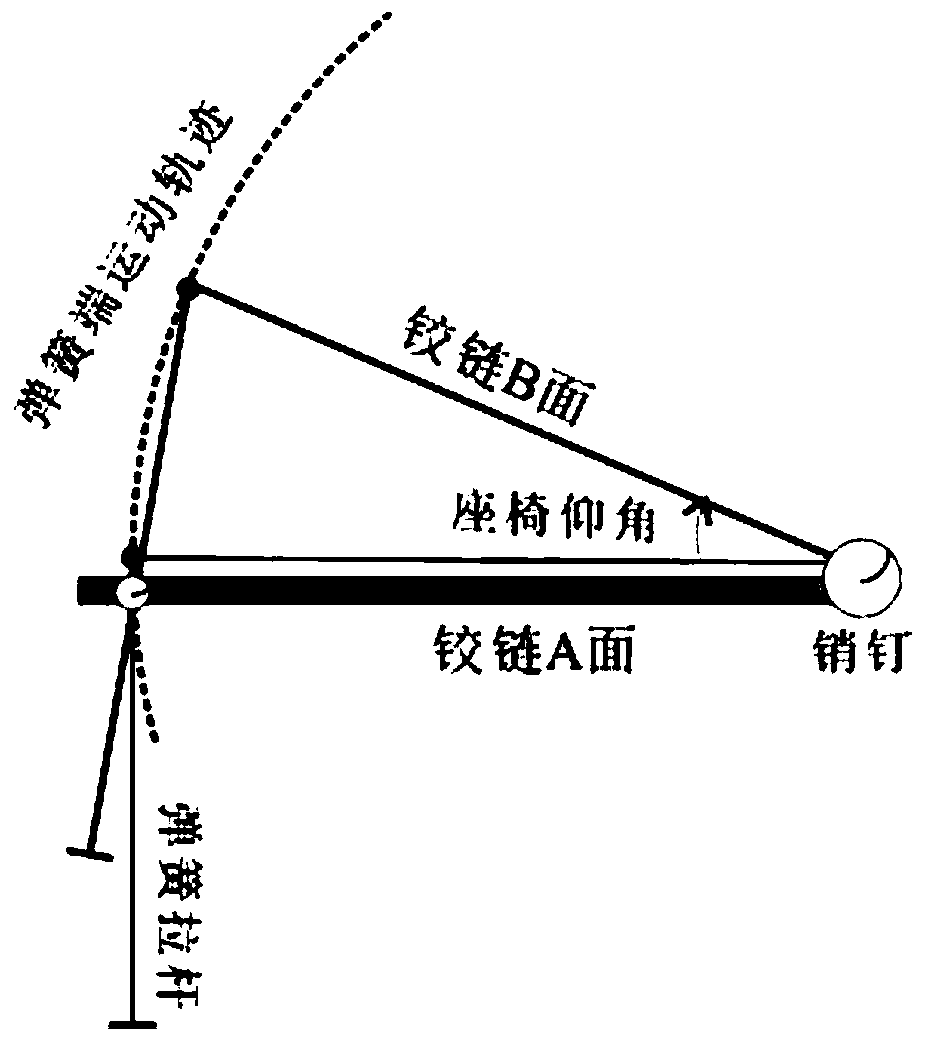

[0082] Such as Figures 1 to 11 , the present invention is applicable to the method for determining the design parameters of the movable mechanism of the spring return seat. The connection hinge and force application device (spring, pull rod) of the lower part of the chair surface are as follows: figure 2 shown. One side of the hinge, B, is fixed to the connecting plate at the seat surface, and the other side, A, is fixedly connected to the seat pillar, and the two are connected by a pin, thus forming a hinge; at the same time, there is a force spring at the lower part of the seat, and a spring is hinged on B. Pull rod, the other end of the pull rod is placed on A, and the pull rod is covered with a force spring. When the user sits on the chair, leans against the back of the chair, and leans back and forth, the spring provides the restoring force, and at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com