Wafer Wet Cleaning System And Method

A technology for cleaning systems, wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

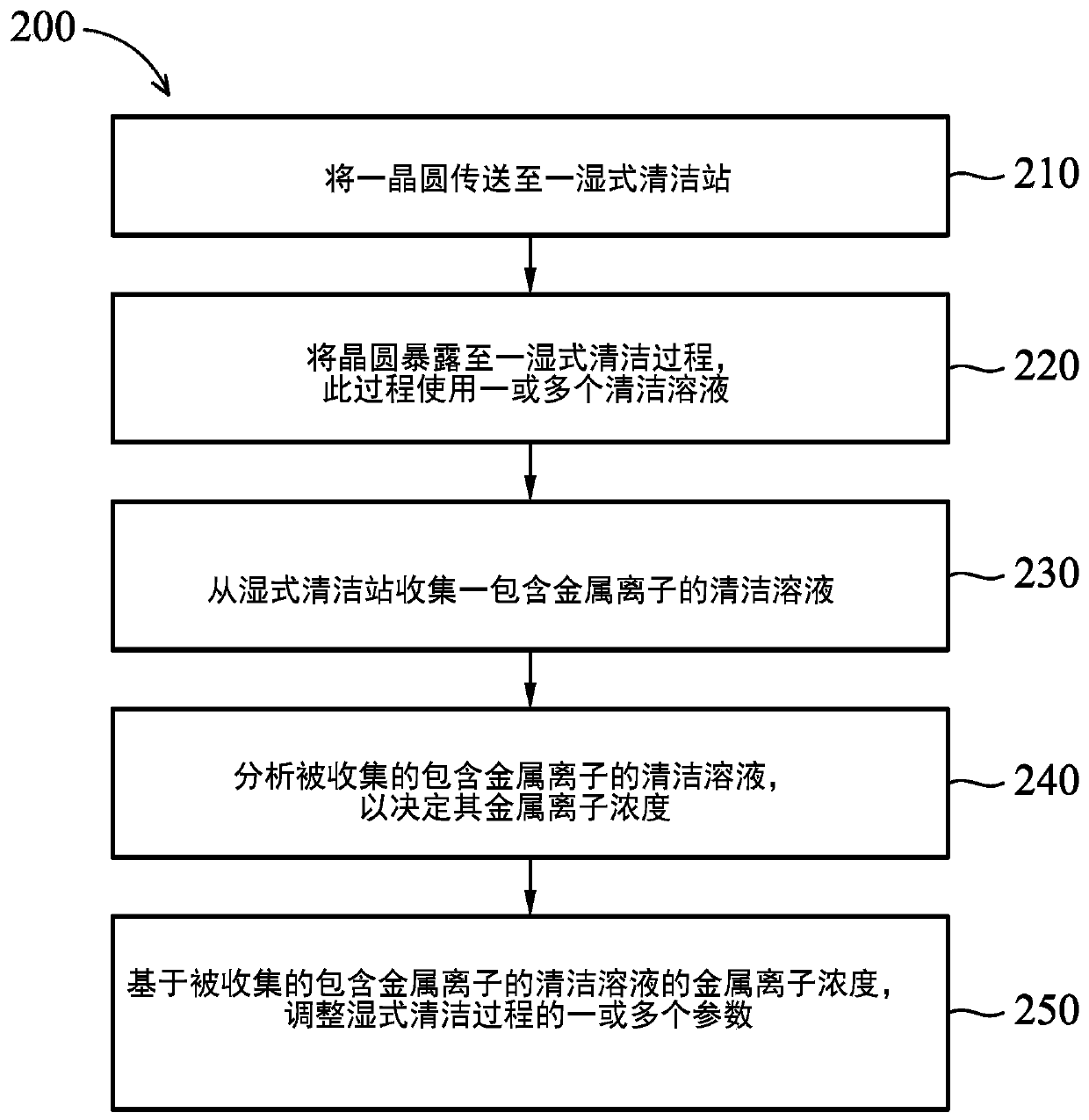

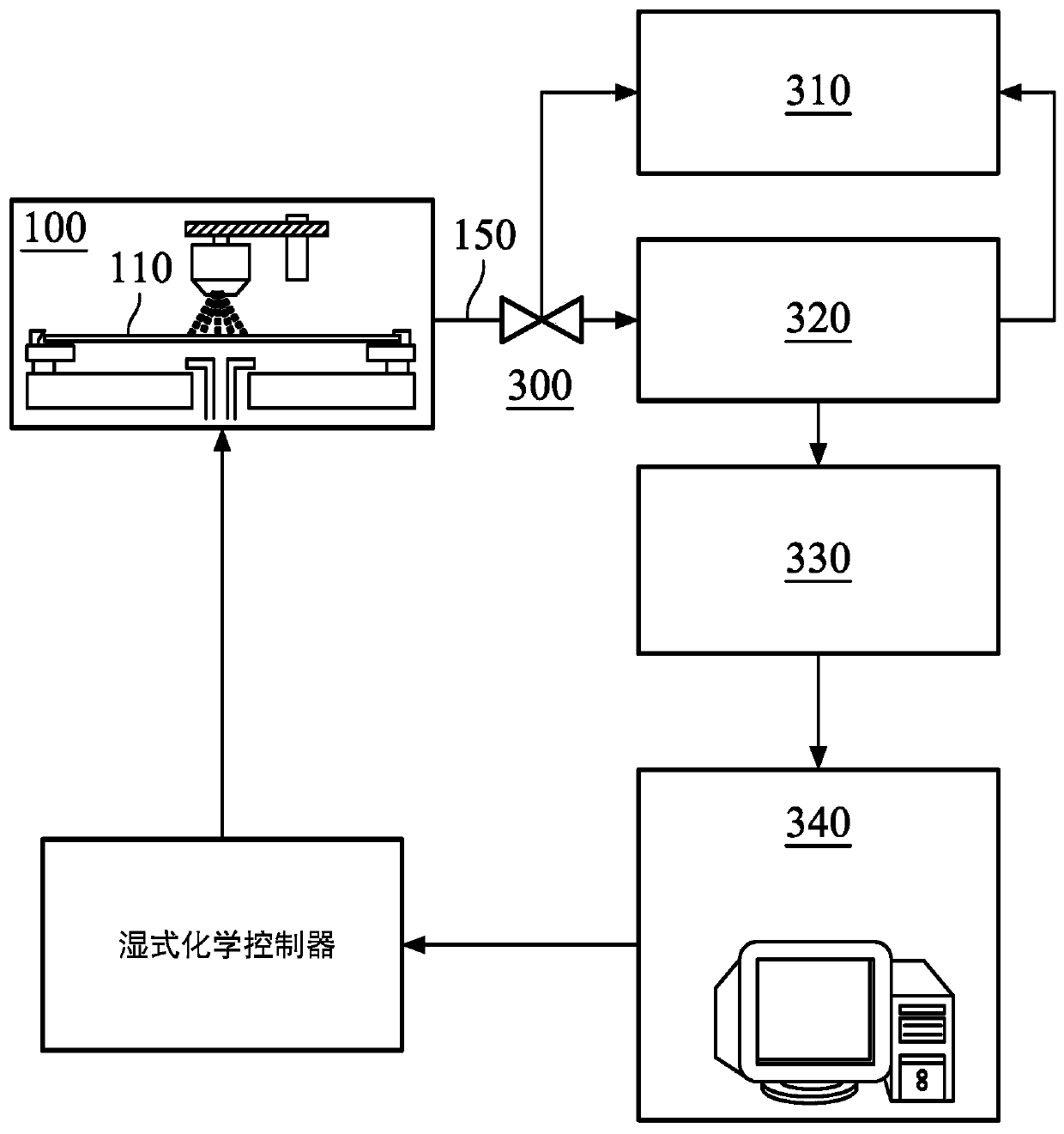

Method used

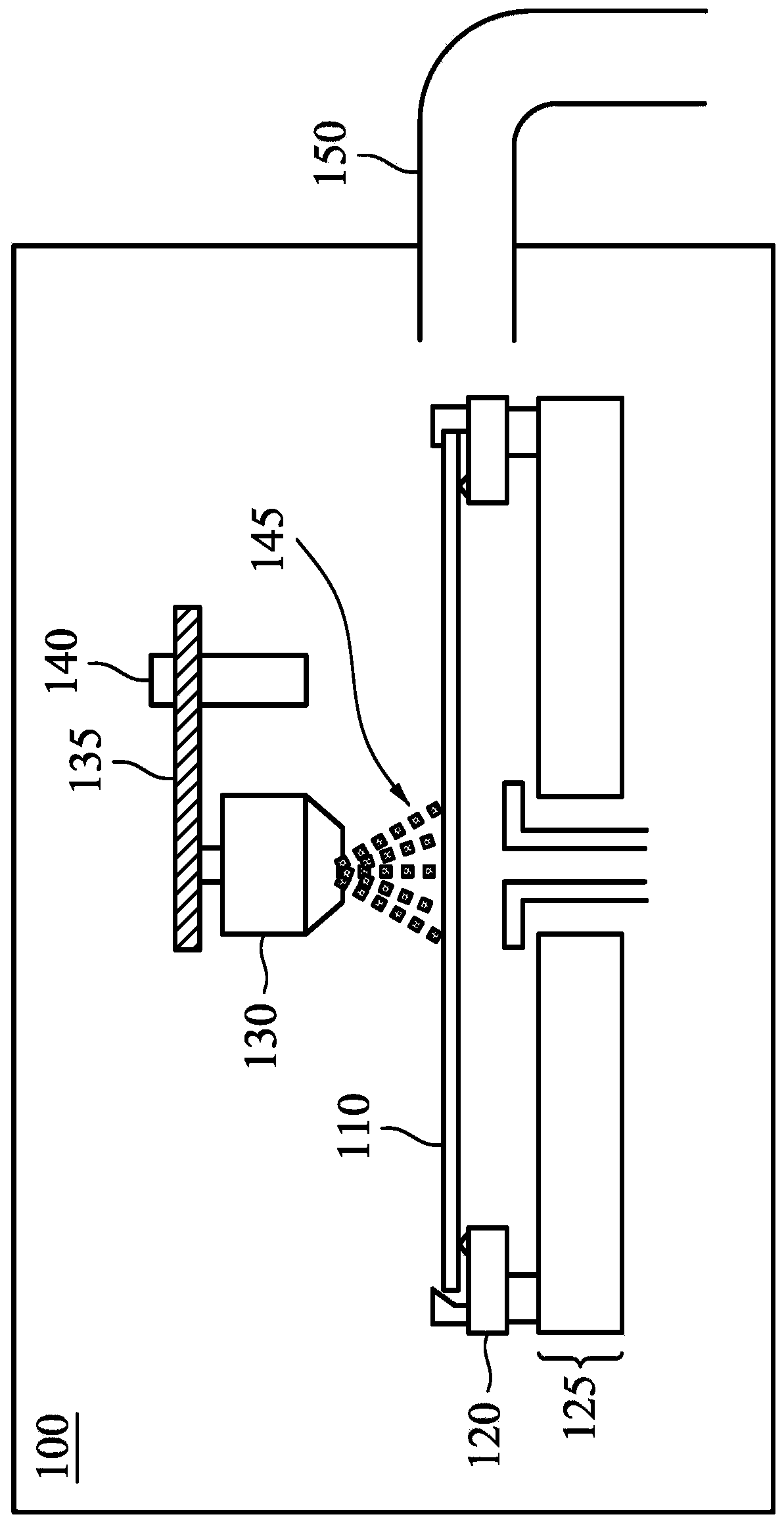

Image

Examples

Embodiment Construction

[0031] Many different implementation methods or examples are disclosed below to implement different features of the provided subject matter, and specific elements and embodiments of their arrangement are described below to illustrate the present disclosure. Of course, these examples are for illustration only, and should not be used to limit the scope of the present disclosure. For example, if it is mentioned in the description that the first characteristic component is formed on the second characteristic component, it may include the embodiment that the first characteristic component is in direct contact with the second characteristic component, and also includes the embodiment where the first characteristic component and the second characteristic component are in direct contact. Embodiments where there are additional features between the second features, ie, the first feature is not in direct contact with the second feature.

[0032] In addition, spatial terms such as "below"...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com